Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Blown film extrusion is a continuous process that melts polymer, extrudes it through an annular die and inflates a tubular bubble that is cooled and collapsed into plastic film rolls, enabling production of bags, tubing and flexible packaging. This guide helps buyers in Soweto and greater Johannesburg understand how blown film extruders work, which machine types match specific applications, and what to consider when evaluating cost, energy use and integration with downstream equipment. Many manufacturers and converters face productivity gaps due to inconsistent gauge control or inadequate line automation; selecting the right extruder reduces material waste and improves finished film quality while boosting throughput. Below we explain the process mechanics, key components, and comparative machine classes, then outline practical buying options, cost guidance and how to integrate extruders with bag makers, flexo printers and recycling systems. Read on to learn technical selection criteria, typical applications in South Africa, and how local suppliers — including Plastic Bag Machine South Africa — support installation, training and aftermarket needs.

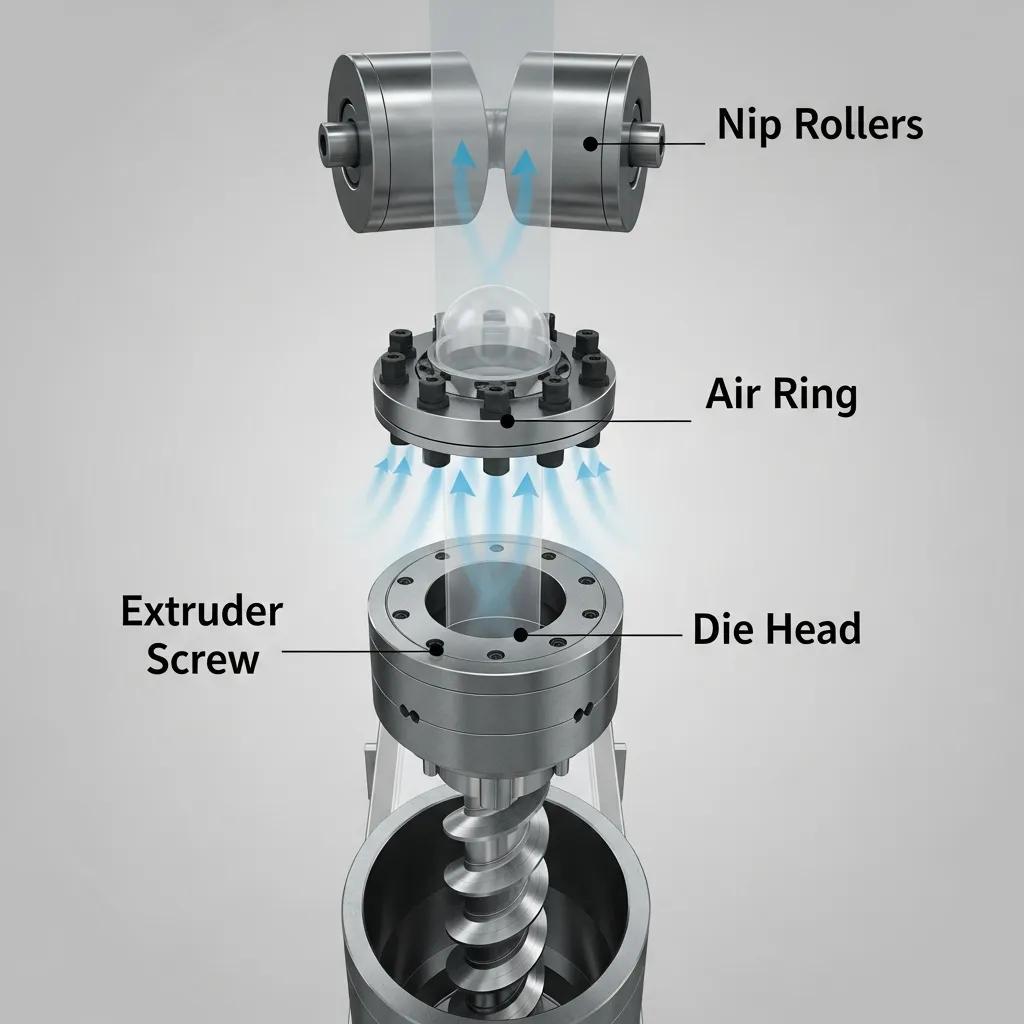

A blown film extruder is a plastic extrusion machine that converts polymer resin into a continuous tubular film by forcing molten polymer through an annular die and inflating the extrudate into a controlled bubble; the result is flexible film with tunable thickness and mechanical properties. The mechanism relies on coordinated control of melt temperature, die gap, air ring cooling and haul-off speed to set gauge, orientation and optical properties, producing film suitable for packaging or converting into bags. Buyers monitor performance through metrics such as output (kg/h), layer count, gauge stability and energy consumption because these determine operating cost and product consistency. Understanding these controls helps when comparing mono-layer and multi-layer lines, as multi-layer capability adds material engineering flexibility for barrier, strength and printable surfaces. The next subsection breaks the process into numbered steps to make the sequence clear and highlight key control points that affect film quality.

The advancements in blown film technology over the years have significantly refined the process, leading to improved film quality and efficiency.

Blown Film Extrusion Technology, Process Control & Materials

The manufacturing technology for blown plastics film has developed considerably in recent years. Advances have been made in die construction (often with computer aided design), in film cooling methods through internal bubble cooling and dual-lip air-rings, and in process control using microprocessor aided automatic systems. The improvements in machinery have increased film output rate, improved quality and reduced scrap while maintaining the inherent flexibility of the process. Additionally, its scientific principles have been studied, producing a greater knowledge of the rheology of film formation and the effects of processing conditions on film properties. The major tonnage of blown film remains in polyethylene, both high and low density, recently augmented by linear low density. Other blown film materials include PVC, EVA, ionomers and nylons. By blending or using co-extrusion, combinations of materials can confer advantageous properties to the resulting film.

Blown Film Production, 1982

The blown film process proceeds in a defined sequence that transforms resin pellets into finished rolls of film through melt, shaping, cooling and winding. First, polymer pellets are fed and melted in the extruder barrel, where screw design and temperature zones create a homogeneous melt ready for extrusion. Second, the melt is forced through an annular die to form a tubular parison; air is introduced through the die tip to initiate bubble formation and maintain internal bubble pressure. Third, an air ring cools and shapes the bubble while nip rollers collapse the bubble into a layflat film and a winder collects the roll; precise control of cooling and haul-off speed adjusts gauge and orientation. Common defects such as film wrinkles, gauge variation or gels relate to temperature fluctuation, unstable bubble inflation or contamination; addressing these points improves yield and consistency.

A standard blown film extruder comprises several ergonomic parts that together determine film quality and uptime: the extruder (screw and barrel), die head (annular die), air ring (cooling and shaping), nip rollers (haul-off), calibration cage and winder. The extruder screw profile and drive influence melt homogeneity and throughput and are critical for processing different polymers, while the die head determines bubble stability and gauge control. The air ring provides forced cooling and bubble shaping—its airflow uniformity directly affects film clarity and thickness uniformity—while the winder and nip system control tension and roll density for downstream converting. Regular maintenance of heaters, thermocouples and bearings reduces unplanned stoppages; choosing machines with accessible components and straightforward maintenance routines reduces downtime and simplifies operator training.

Blown film extruders available locally span mono-layer single-screw lines to multi-layer co-extrusion systems, with models designed for HDPE, LDPE and LLDPE processing and differing in throughput, automation and layer-count capability. Machine selection depends on target products—simple shopping bags often need cost-effective mono-layer lines, while barrier or laminated films call for 3-layer or more multi-layer co-extrusion lines to combine different polymers.

The table below summarizes machine types, typical output ranges and common polymer targets to help buyers compare options quickly before reviewing price and integration considerations.

This EAV table compares machine classes to typical applications and output bands.

| Machine Type | Typical Layers / Output (kg/h) | Typical Polymers / Applications |

|---|---|---|

| Mono-layer single-screw | 50–300 kg/h | LDPE/LLDPE for simple bags, liners and film |

| 3-layer co-extrusion | 150–800 kg/h | Combinations (LDPE/LLPE/HDPE) for barrier film and printed packaging |

| Twin-screw multi-layer | 200–1,200 kg/h | LLDPE blends, recycled-content films, technical films |

This comparison helps buyers map production scale to machine classes and clarifies when a multi-layer investment yields material or performance advantages.

The next subsections contrast mono-layer and multi-layer architectures and explain polymer-specific applications and processing adjustments.

Mono-layer lines extrude a single polymer layer and are typically simpler, lower-cost and easier to operate, making them suitable for commodity bags and lower-spec films. Multi-layer co-extrusion lines stack several polymer layers via multiple extruders and a co-extrusion die, enabling barrier layers, adhesive tie layers and surface layers optimized for printing or sealing. Advantages of multi-layer machines include improved barrier performance, better mechanical properties and material savings through layer engineering, while disadvantages include higher capital and maintenance complexity. For many converters, mono-layer remains cost-effective for unprinted retail bags, but multi-layer pays off when product differentiation, reduced raw material cost or recycled-content incorporation is required. Understanding these trade-offs informs whether to prioritise low capital outlay or long-term material efficiency.

Different polyolefins produce films with distinct mechanical and optical attributes and require tailored processing settings, so machine configuration and screw design must match the polymer. HDPE yields stiffer, higher-crystallinity films suited to heavy-duty sacks and carrier bags, while LDPE provides excellent clarity and sealability for grocery bags and shrink films; LLDPE combines strength and puncture resistance making it versatile across many bag types. Processing notes include higher melt temperatures and shear sensitivity differences—HDPE needs robust melt-handling and often higher torque drives, whereas LDPE benefits from gentle shear to retain clarity. Adjusting cooling, blow-up ratio and haul-off speed permits tuning of film stiffness and gauge to meet specific end-use requirements.

Further research delves into how specific process parameters directly influence the molecular structure and resulting properties of these polyethylene films.

Polyethylene Blown Film Properties & Process Parameter Effects

ABSTRACT: AbstractMolecular orientation and structure development during film blowing have a major effect on mechanical and physical properties of polyethylene films. In this work the structures and morphology of three different polyethylene blown films; linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), and high density polyethylene (HDPE) were studied. A series of blown films were produced at different process conditions. The orientation of lamellae and lamellar stacks and the morphology of the films were characterized by SEM, AFM and X-ray diffraction. SEM images of the film plane surface MT (Machine-Transverse) and cross section slices in TN (Transverse- Normal) and MN (Machine-Normal) planes were made and compared with AFM images. It was observed that the surface morphology reflects a continuation of the bulk morphology for the cases studied. Changes in the blown film process parameters, such as take up ratio (TUR), blow up ratio (BUR) and frost line height (FLH) have

Investigation on the structure and properties of different PE blown films, A Ajji, 2007

Plastic Bag Machine South Africa operates as a lead-generation partner for suppliers and works with manufacturers that provide blown film extruders and complementary equipment, positioning itself as a one-stop source for film production lines and after-sales support. The company highlights simple operation and easy maintenance as practical benefits that reduce training time, while emphasizing performance reliability and timely after-sales service to keep lines running in production environments. Buyers in Soweto benefit from localised support for installation and commissioning, access to spare parts and a supplier network capable of customization and R&D-led solutions for specific film formulations.

Machines offered through Plastic Bag Machine South Africa emphasize build quality and measurable performance attributes such as stable gauge control, reliable bubble management and energy-efficient drive options that lower operating cost per kilogram of film produced. Equipment often includes serviceable designs that simplify regular maintenance and spare parts replacement, while warranty elements—such as the noted two-year warranty on timer switches—provide buyers with a degree of quality assurance. Automation options such as PLC control and automatic gauge control reduce operator dependence and improve roll-to-roll consistency, which in turn increases yield and reduces scrap. Buyers should prioritise features that directly impact uptime and product consistency when comparing supplier offers.

Local service and after-sales support shorten response times for spare parts and technical assistance, enabling quicker restoration of production after faults and reducing prolonged downtime. Plastic Bag Machine South Africa and its manufacturing partners provide installation support, operator training and commissioning to ensure lines run to specification from first production, and they can supply replacement components and maintenance guidance when needed. Having a supplier network that offers customization and R&D capability helps converters adapt recipes and layer structures for local markets and recycling streams, improving product fit and cost-efficiency. These service benefits translate into faster start-up, more consistent film output and predictable maintenance cycles for Soweto-based operations.

Blown film extruders serve a wide range of South African industries by producing flexible packaging, retail bags, industrial liners and agricultural films; their versatility makes them foundational equipment for local converters and brand packagers. Film produced on blown lines can be used for printed retail bags, t-shirt bags, refuse sacks, shrink film, pallet wrap and heavy-duty liners, each requiring different gauges, layer structures and mechanical properties. Converters also add value through flexo printing and lamination to create branded retail packaging or multi-material structures tailored to shelf requirements. The following lists and examples show primary application categories and the production considerations that link product type to machine selection.

Blown film lines produce material for common packaging and industrial needs in South Africa:

These application clusters help manufacturers decide on gauge control, layer count and polymer selection, directing the next discussion to packaging-specific uses.

Blown film is the dominant method to produce numerous flexible packaging formats due to its cost-effectiveness, mechanical strength and ease of sealing, enabling high-speed bag making and printing. Manufacturers choose blown film for grocery bags, t-shirt bags, produce bags and lamination substrates where consistent gauge and good seal integrity are important, and many converters use flexo printing downstream to apply branding directly to film rolls. Typical gauge ranges vary by product—very thin retail films for carry bags versus thicker gauges for refuse bags—and film orientation and additive choices influence barrier and mechanical properties. Combining blown film lines with printing and bag-making allows converters to produce finished products in-line or near-line, reducing handling and improving turnaround.

Blown film extruders produce a broad set of industrial films including heavy-duty liners, pallet wrap, pond liners, mulch film and silo covers that demand durability, tear resistance and UV stability for outdoor or industrial use. Machines with higher output and multi-layer capability are preferable when producing thick films or when incorporating reinforcements and barrier layers, because layer engineering delivers the combination of mechanical strength and cost-effective raw material use. For agricultural applications, additives for UV resistance and increased thickness help extend field life, while industrial liners may require specific film chemistries for chemical resistance. Selecting the right extruder features—robust torque, good thickness control and reliable winding—ensures consistent production of high-performance industrial and agricultural films.

Estimated costs for blown film extruders in South Africa vary widely based on new vs used condition, layer count, automation and capacity, so buyers should use price bands as a starting point and request tailored quotes for exact specifications. New basic mono-layer single-screw lines typically start at lower capital levels, while multi-layer co-extrusion lines with higher automation and throughput command a premium; used or refurbished units offer lower upfront cost but require careful inspection and potentially higher maintenance risk. Financing, leasing and refurbished options allow converters to balance cash flow and capacity expansion, and evaluating total cost of ownership—including energy use, spare parts availability and expected uptime—is critical to calculating realistic payback periods.

Intro to price comparison table: this table gives indicative ranges and considerations for new, used and refurbished options.

| Option | Price Range (indicative) | Warranty / Lead Time |

|---|---|---|

| New mono-layer line | Mid-range capital cost | Manufacturer warranty; longer lead time |

| New multi-layer co-extrusion | Higher capital cost | Warranty; longer lead time due to customization |

| Used / Refurbished | Lower upfront cost | Shorter or limited warranty; shorter delivery time |

After reviewing these options, buyers should request a personalised quote and technical sheet to compare exact specs, rather than relying solely on indicative bands.

Price drivers include throughput (kg/h), number of layers, control and automation level, condition (new/used) and customization requirements; these variables create broad price bands rather than fixed prices. New mono-layer lines serve small converters affordably while multi-layer or high-output lines represent larger investments but deliver lower material cost per unit produced; used machines reduce capital cost but require careful inspection of screw condition, bearings and control systems. Buyers should request on-site inspections or remote technical audits for used equipment, confirm spare-parts availability and verify any warranty terms. To obtain precise pricing and financing options, Soweto buyers are encouraged to contact local suppliers and request tailored quotes that reflect their expected throughput and product mix.

At the end of this section, consider formal quote requests and financing: Plastic Bag Machine South Africa can facilitate quotes, discuss new versus used options and outline potential financing pathways to match budget and production goals.

ROI evaluation requires calculation of payback period using inputs such as capital cost, expected throughput (kg/day), product margin, energy cost per kWh, and anticipated yield improvements from better gauge control and reduced scrap. A simple ROI formula is: Payback (years) = Capital Cost / (Annual Net Benefit), where Annual Net Benefit = (Additional annual profit from increased throughput and yield) + (energy and labour savings) − (additional operating costs). Energy-efficiency features—such as energy-efficient motors and optimized screw profiles—reduce cost per kilogram and shorten payback, making them important selection criteria for long-term operations. Collecting realistic production data and running scenario analyses for throughput, scrap reduction and energy savings offers a clear path to compare machine options on total cost of ownership rather than purchase price alone.

Integrating blown film extruders with downstream bag-making, flexo printing and recycling equipment creates efficient production lines that reduce handling, improve production continuity and enable higher-value finished products. Successful integration requires matching web speeds, tension control, winding specifications and electrical/automation interfaces so that extruder output aligns with bag makers and printers; mechanical and control compatibility is essential for in-line or near-line configurations.

The table below outlines common machine pairings, their role in the line and interface considerations to help planners design cohesive production workflows and evaluate vendor compatibility before purchase.

| Machine | Role in Line | Required Interfaces / Notes |

|---|---|---|

| Plastic bag making machine | Converts film into bags/packaging | Requires consistent web width, tension and roll diameter control |

| Flexo printing machine | Applies graphics / branding | Needs synchronized web speed and tension control for registration |

| Plastic recycling machine | Reprocesses trim and regrind | Requires pelletizing or compatibilizer handling and consistent feedstock |

These integration notes guide procurement teams when specifying electrical, mechanical and automation compatibility to ensure smooth inline operation.

The next subsections discuss practical benefits of pairing extrusion with bag makers and the value added by printing and recycling.

Pairing blown film extruders directly with bag making equipment reduces material handling, shortens production lead times and lowers labor costs, as rolls can be transferred directly or when configured in-line can feed the bag-maker continuously. Integrated lines improve traceability and reduce risk of contamination or damage during transport between processes, yielding higher first-pass quality and less scrap. Options range from semi-automatic near-line setups for mid-scale operations to fully integrated continuous lines for high-volume converters, and the right choice depends on target throughput and capital constraints. Implementing integrated lines also simplifies workflow planning and inventory control, which supports predictable scheduling and improved overall equipment effectiveness.

Flexo printing integrated with blown film lines enables brand differentiation and higher margins by allowing on-roll graphics and variable print runs that align with market demand, but it requires synchronization of web speed and precise tension control for accurate color registration. Incorporating recycling—either through regrinding trim for direct refeed or using dedicated recycling machines to produce reclaim pellets—reduces raw material cost and supports sustainability goals, though it demands attention to contamination control and compatibilization to maintain film properties. Coordinating printing and recycling with extrusion requires process engineering to preserve film quality and prevent contamination; when done correctly, these integrations add commercial value, reduce waste and enable production of recycled-content films that meet evolving customer and regulatory expectations.

These steps help manufacturers structure investments that produce measurable improvements in throughput and product value.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.