Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Blown film extrusion machines convert polymer resins into continuous plastic film suitable for bags, packaging, and agricultural films, offering Soweto manufacturers a productive route to in-house film production and lower material costs. This guide explains how blown film extrusion works, which machine types are common in Gauteng and Soweto, material compatibility, and how extruders integrate with downstream plastic bag making and printing equipment to create finished products. Many small and medium producers face procurement decisions about output capacity, layer structure, and service support; understanding machine components, process variables, and local supplier channels helps reduce downtime and match equipment to production goals. The article covers core process steps and components, compares monolayer and co-extrusion options, outlines material and recyclate considerations, and explains where to source equipment and what to verify before purchase. Throughout we reference practical buyer criteria, EAV comparison tables, and local service realities so you can evaluate blown film extrusion machines for sale in Soweto with confidence.

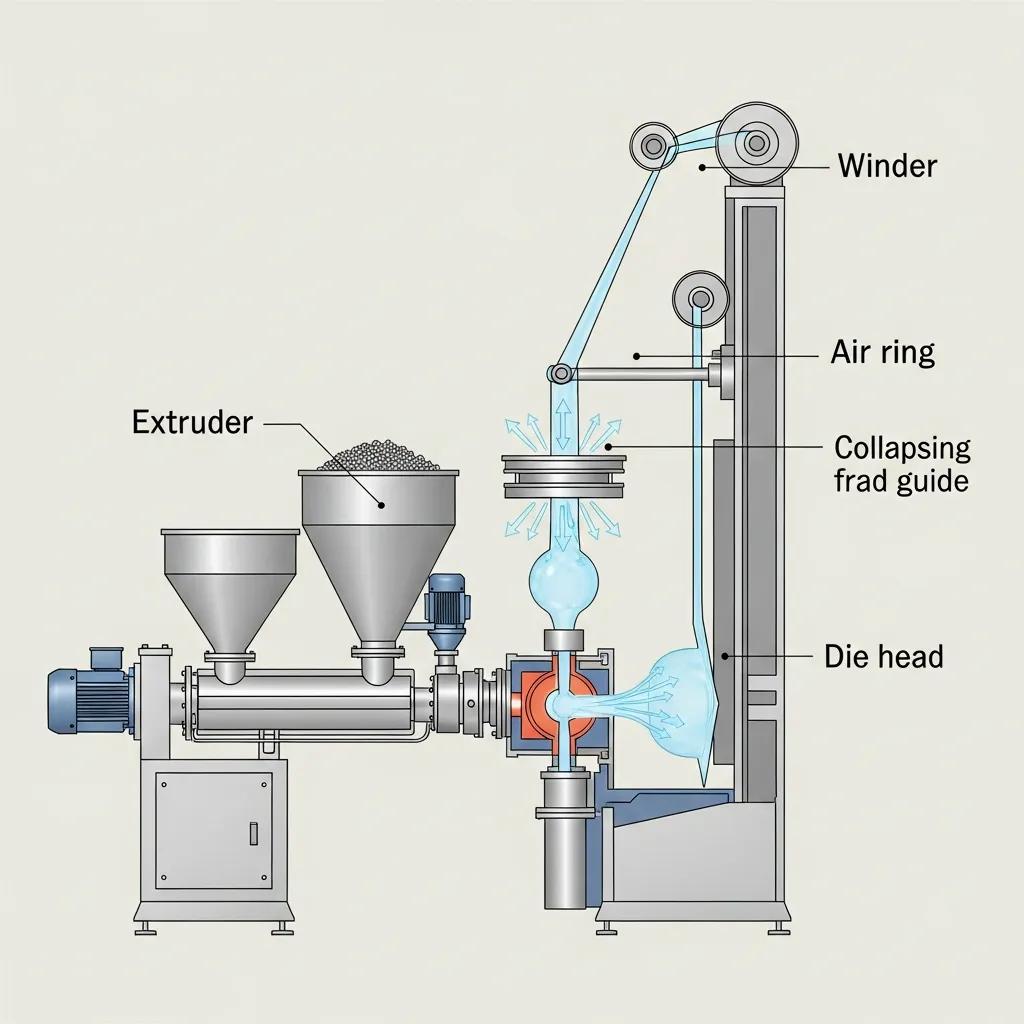

Blown film extrusion machines are plastic extrusion systems that melt polymer resin and form it into a thin tubular film by forcing molten melt through a circular die and inflating the extruded tube with air to create a bubble; this process produces continuous film rolls for conversion into bags or laminates. The mechanism combines controlled melt extrusion, bubble inflation using an air ring, cooling, nip flattening, and winding so that film properties like thickness, clarity, and mechanical strength result from screw design, blow-up ratio, and cooling efficiency. Understanding the process helps buyers specify screw diameter, L/D ratio, and die geometry to meet output and film-quality targets, and it sets the stage for comparing monolayer and co-extrusion solutions. The following subsections break the process into operational steps and describe the main machine components so you can match equipment features to production requirements.

The blown film process begins with raw resin feeding, melt extrusion through a screw, die formation into a tubular melt, inflation into a bubble, cooling, flattening, and winding; each stage influences film gauge, strength, and optical properties. Process variables include temperature zone settings, screw speed and L/D ratio, blow-up ratio (diameter of bubble vs die), and haul-off tension, and controlling these variables optimizes properties needed for grocery bags, garbage bags, or agricultural film. Common operational tips for South African conditions include correct drying of hygroscopic resins, staged temperature profiling for LDPE/LLDPE vs HDPE, and stable air ring control to avoid bubble collapse or gauge variation. Mastering these steps improves yield and reduces scrap, which leads naturally to attention on specific machine components that enable this control.

A typical blown film line includes the extruder and screw, die head and air ring, haul-off/ nip rollers, and a winder with tension control; advanced lines add co-extrusion feeds, corona treatment, and film gauging systems for precision. The extruder screw controls melt homogeneity and throughput, where attributes like screw diameter and L/D ratio determine output and melt stability, while the die head and air ring shape and cool the bubble to set film thickness and surface properties. Winder systems and control panels maintain roll quality and tension to prevent wrinkles and gauge variation, and buyer notes should focus on serviceability of these components and availability of spare parts. With components understood, manufacturers can select appropriate machine types and configurations for their product mix and downstream bag making needs.

Blown film extrusion machines in Gauteng and Soweto range from simple monolayer lines for basic films to multi-layer co-extrusion lines that combine functional layers for barrier or mechanical performance, and the right choice depends on product requirements and budget. Monolayer lines are cost-effective and simpler to operate, while co-extrusion lines enable combinations like sealant layers, barrier layers, or CaCO3-filled cost reducers; choosing between HDPE-focused and LDPE/LLDPE-focused machines depends on film stiffness and flexibility needs. Below is a comparison table to clarify machine types, typical outputs, materials, and practical advantages so buyers can map production targets to capacity and layer structure requirements.

Introductory table showing typical machine types and selection guidance:

| Machine Type | Materials | Typical Applications | Output Range (kg/h) |

|---|---|---|---|

| Monolayer blown film extruder | LDPE, LLDPE, HDPE | Shopping bags, simple packaging films | 50–400 |

| Co-extrusion multi-layer line | LDPE/LLDPE + barrier/functional layers | Barrier film, laminated packaging, printed film | 100–1,200 |

| HDPE film blowing machine | HDPE blends | Stiffer carrier bags, retail sacks | 80–600 |

This table helps buyers match product type, material, and expected output when evaluating machines, and the next subsection explains monolayer vs co-extrusion tradeoffs in more depth.

Monolayer machines extrude a single polymer melt and are prized for simplicity, lower capital cost, and easier maintenance; they suit basic bag and film products where single-material properties suffice. Co-extrusion lines feed multiple extruders into a multilayer die to produce films with functional layers for improved barrier, sealability, or mechanical performance, making them ideal for applications requiring laminated structures or filler inclusion like CaCO3. The tradeoff is higher complexity and control requirements—co-extrusion needs more sophisticated control panels, layer thickness monitoring, and synchronization between extruders—so buyers should weigh long-term product flexibility against initial capital and operator skill availability.

HDPE film blowing machines produce stiffer, higher-modulus films used for grocery bags, heavy-duty carrier sacks, and applications needing tear resistance, while LDPE/LLPE equipment yields more flexible, clear films suitable for shopping bags, shrink films, and soft packaging. Key distinguishing features include screw design tuned to melt index, die lip geometry for edge properties, and cooling strategy to balance clarity against orientation; HDPE lines often require higher processing torque and careful temperature profiling. Selecting between HDPE and LDPE/LLPE lines depends on end-use requirements such as stiffness, seal strength, and clarity, and connects directly to downstream bag making equipment choices.

Blown film extruders supply continuous film that downstream plastic bag making machines convert into finished bags through printing, cutting, sealing, and perforation, and efficient integration between extruder and bag maker is critical for consistent production. Production lines for shopping bags or garbage bags typically include corona treatment and flexo printing upstream of the bag cutter/sealer, and synchronization of line speeds, tension control, and registration ensures correct print alignment and consistent bag dimensions. This section outlines integration points, common pitfalls when linking extruders to bag makers, and recommendations for achieving stable production with minimal waste.

Before listing integration tasks, here are core integration steps that link extrusion to finished bag production:

These integration steps form the basis for designing a reliable production line and lead into specifics about how film output is transformed into bags and the equipment cooperation required.

Film from the extruder is flattened, printed, and sent to bag making machines where slitting, cutting, sealing, and handle attachment occur; print registration and tension control are primary technical challenges during integration. Synchronization requires feedback between the extruder winder and the bag maker’s unwind station so that roll diameter changes and line speed shifts do not upset registration or cause web breaks, and practical recommendations include phase-locked speed control and inline thickness gauging. Proper integration reduces scrap, ensures print alignment for flexo printing, and enables higher overall throughput while allowing simultaneous operation of multiple downstream machines. Addressing these operational linkages naturally leads to considerations for full extrusion lines designed for larger packaging and agricultural film outputs.

Larger industrial extrusion lines combine high-output extruders, multi-manifold co-extrusion dies, wide-width winders, and advanced cooling systems to produce films for packaging, lamination, and agriculture; these lines emphasize uniform gauge across wide widths and robustness for long production runs. Design considerations include wider die lips, higher extrusion torque, multi-lane winding, and sometimes slitters or inline printing modules to support roll sizes demanded by converters and agricultural users. Recommended capacities depend on end use—packaging converters often require stable mid-to-high outputs with excellent surface finish for printing, while agricultural films prioritize UV stability and thickness uniformity. Understanding line configuration at this scale helps buyers plan factory layout and power/service needs before committing to equipment.

Buyers choosing a supplier value quality assurance, local support, customization options, and clear delivery timelines, and Plastic Bag Machine South Africa positions its offering around these buyer concerns. The company operates as a local presence for a larger manufacturer, emphasizes simple operation and easy maintenance, and claims local after-sales service across major South African cities; these attributes address operational risk, spare parts access, and training needs that matter to Soweto manufacturers. Below is the required business statement followed by how the stated product offerings map to common buyer needs.

Plastic Bag Machine South Africa operates as a local presence for Kingdom Machinery Co., Ltd. The company emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service, with a presence in Gqeberha, Soweto, Cape Town, and Johannesburg. Primary products include Blown Film Extrusion Machines, Plastic Bag Making Machines, Flexo Printing Machines, and Plastic Recycling Machines. Stated unique value propositions: comprehensive product range, 100 percent final inspection during production, two-year warranty on timer switches, strong R&D capabilities, one-stop customization service, competitive pricing due to large-scale production, and fast delivery (25-30 days for standard machines). The website is organized by product categories and includes solutions, about us, news, and FAQs.

The stated 100 percent final inspection during production addresses quality control expectations by asserting a manufacturing check before shipment, while a targeted two-year warranty on timer switches highlights a specific component guarantee that may reduce early operational risk. Local support and after-sales service availability in major South African centers responds to common buyer concerns about maintenance and spare parts lead times, and R&D capabilities and customization services potentially shorten time to market for product variants. Evaluating these claims against documented evidence—inspection reports, spare parts lists, and service SLAs—helps ensure the supplier’s promises translate into reliable field performance and sets up the next discussion on delivery and customization timelines.

Customization options and a one-stop service model mean buyers can specify layer counts, film widths, and integration packages for extruder plus bag maker and printing lines, which simplifies procurement compared with sourcing separate vendors. Fast delivery for standard machines (reported as 25–30 days) is advantageous for reducing lead time, but buyers should confirm production schedules and shipping terms before ordering to align with factory readiness and installation windows. Local after-sales presence supports commissioning, operator training, and rapid spare part dispatch—factors that materially reduce downtime and total cost of ownership—so prospective buyers should request detailed delivery and service plans during quoting.

Blown film extrusion machines process a range of polyolefins and specialty blends, commonly including HDPE, LDPE, LLDPE, and increasingly biodegradable polymers and recyclate blends; each material has processing nuances that affect equipment choice and line settings. Processing notes include melt index ranges, drying needs for certain polymers, and expected impacts on clarity, sealability, and mechanical properties; understanding these material behaviors helps select screw geometry, die design, and cooling strategies. The table below summarizes material compatibility, recommended processing notes, and typical products so manufacturers can map material decisions to target applications.

| Material | Processing Notes | % Recyclate Compatibility | Typical Products |

|---|---|---|---|

| HDPE | Requires higher torque and cooler profiles for stiffness retention | 0–30% typical without compounding | Carrier bags, retail sacks |

| LDPE/LLDPE | Wide processing window, good sealability and clarity | 10–40% depending on quality | Flexible shopping bags, liners |

| Recycled polyolefin | Pre-drying, filtration; monitor melt strength and contamination | Variable; blends often used to reduce cost | Low-grade packaging, refuse sacks |

| Biodegradable polymers | Require specific temperature profiles and may need isolation | Low; sensitive to contamination | Compostable bags (limited use) |

| CaCO3-filled compounds | Improve stiffness and reduce cost; increase abrasion | Limited unless compatibilized | Cost-effective agricultural and liners |

This comparison clarifies tradeoffs between material cost, performance, and processability and leads into specific guidance on processing each class of material.

HDPE is processed at higher shear and yields stiffer films suited for robust carrier bags, while LDPE and LLDPE provide flexibility and sealability for retail and garbage bags; screw design and temperature control must match the resin’s melt index for stable extrusion. Biodegradable polymers need careful moisture control and are less tolerant of recyclate contamination, which can limit recyclate percentages and require equipment isolation to avoid cross-contamination. Choosing the right material also connects to downstream requirements like printing and sealing, so material selection should be coordinated with converter needs and end-use standards to ensure functional performance.

Blending recyclate or CaCO3 fillers alters melt strength, clarity, and stiffness—recyclate can reduce clarity and melt strength while CaCO3 increases stiffness and lowers material cost—so recommended best practices include incremental blending trials, suitable screw metallurgy, and filtration to handle contaminants. Typical blending ratios depend on quality goals: moderate recyclate loads preserve functional properties while higher filler levels reduce material cost but require optimized screw and die designs to manage dispersion. Proper testing and compatibility checks prevent downstream sealing and printing problems, and manufacturers should expect to adjust process parameters and possibly install inline filtration or melt pumps when processing high recyclate or filled compounds.

Buyers typically locate blown film extrusion equipment through direct manufacturer channels, local agents or distributors, and used-equipment brokers; each channel presents different tradeoffs in warranty coverage, customization, and service response. The following required business statement is provided as lead-in to local purchase options and pathways, after which practical verification steps and comparison tips help buyers evaluate offers.

Plastic Bag Machine South Africa operates as a local presence for Kingdom Machinery Co., Ltd. The company emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service, with a presence in Gqeberha, Soweto, Cape Town, and Johannesburg. Primary products include Blown Film Extrusion Machines, Plastic Bag Making Machines, Flexo Printing Machines, and Plastic Recycling Machines. Stated unique value propositions: comprehensive product range, 100 percent final inspection during production, two-year warranty on timer switches, strong R&D capabilities, one-stop customization service, competitive pricing due to large-scale production, and fast delivery (25-30 days for standard machines). The website is organized by product categories and includes solutions, about us, news, and FAQs.

Below is a supplier evaluation checklist to use when comparing machines and channels.

Summary paragraph: Applying this checklist when soliciting quotes ensures you compare like-for-like offers and highlight service and warranty differences that materially affect long-term ownership costs, which prepares you to request full spec sheets and demonstrations.

Local suppliers include direct manufacturer representatives, specialized distributors, and equipment brokers; when evaluating any local partner, verify their technical support footprint, spare parts availability, and references for installation and commissioning. Important verification steps include asking for documented inspection and test reports, clarity on lead times for spare parts, and whether on-site training and startup assistance are included in the purchase. These checks reduce the risk of prolonged downtime and ensure that the selected partner can support production scale-up, which leads to cost and specification comparisons you should perform next.

Price drivers include number of layers, screw diameter and output capacity, automation level, and included downstream equipment such as winders or corona treaters, and buyers should request full specification sheets and EAV comparison tables to make objective choices. Use the comparison checklist below to focus negotiations and ensure delivered equipment meets performance targets.

Summary paragraph: Following this approach helps you request EAV tables and full spec sheets, compare total installed cost, and verify delivery and installation charges before awarding purchase orders to ensure alignment with factory timelines and budgets.

Plastic Bag Machine South Africa operates as a local presence for Kingdom Machinery Co., Ltd. The company emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service, with a presence in Gqeberha, Soweto, Cape Town, and Johannesburg. Primary products include Blown Film Extrusion Machines, Plastic Bag Making Machines, Flexo Printing Machines, and Plastic Recycling Machines. Stated unique value propositions: comprehensive product range, 100 percent final inspection during production, two-year warranty on timer switches, strong R&D capabilities, one-stop customization service, competitive pricing due to large-scale production, and fast delivery (25-30 days for standard machines). The website is organized by product categories and includes solutions, about us, news, and FAQs.

Request a quote or contact sales to schedule a demonstration and discuss customization, delivery times, and local installation options.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.