Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

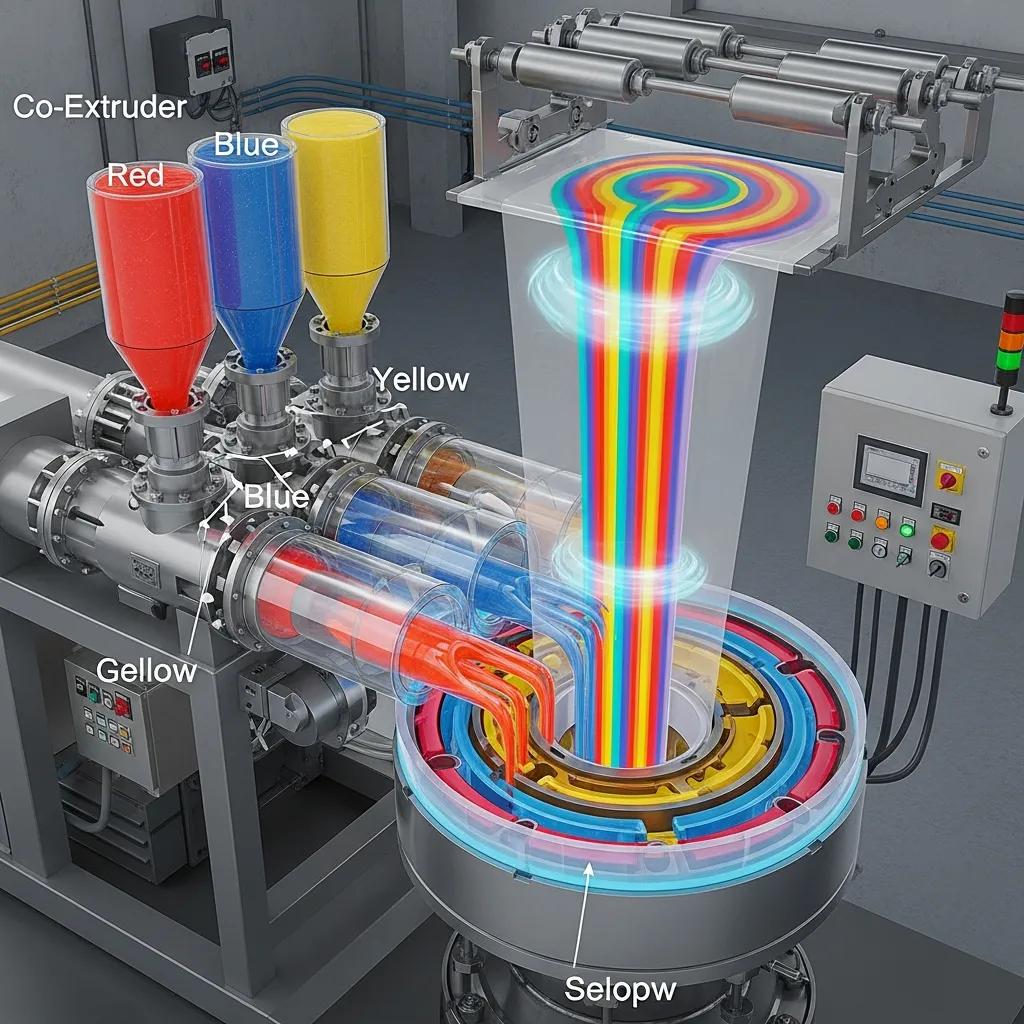

Multi layer blown film extrusion produces composite plastic films by co-extruding two or more polymer melts through a single die to form a concentric bubble, enabling tailored combinations of barrier, mechanical strength, and sealability in a single production step. This guide explains the core mechanics, common polymers, and the features buyers should prioritise when selecting a high-performance blown film extruder, with practical insights for South African manufacturers and converters. Readers will learn how co-extrusion die heads and internal bubble cooling work together to control gauge and optical properties, why gravimetric dosing and automatic winders improve yield and efficiency, and how different layer counts (3-, 5- and 7-layer) map to specific applications. The article also covers sustainability options—using recyclates, biodegradable layers, and energy-saving drives—and provides an actionable vendor checklist to evaluate equipment offerings. Throughout, we reference local support and supply considerations relevant to leading representatives in South Africa while keeping technical decision-making front and centre.

Multi layer blown film extrusion is a co-extrusion process where multiple extruders feed distinct polymer melts into a concentric die head that forms a single bubble, producing laminated films with layer-specific functions. The mechanism uses synchronized screw speed and melt pressure control to maintain consistent layer ratios while a cooling system and nip/winder regulate bubble size and film gauge, producing films with tailored barrier, seal, and mechanical properties. Benefits include targeted material placement that reduces overall resin cost, improved barrier performance without lamination, and flexibility to combine virgin, filler, or recycled resins for specific end-use needs. For manufacturers choosing equipment, multi-layer systems are ideal when product performance requires discrete layer roles such as a tough outer skin, a puncture-resistant core, and a sealable inner layer; this capability underpins modern packaging, courier film, and industrial liners.

Plastic Bag Machine South Africa represents multi-layer blown film extrusion lines in the local market and offers machine classes suitable for 3-, 5- and 7-layer co-extrusion lines, with options that accommodate different factory layouts and production targets. This local representation provides a practical channel for sourcing co-extrusion die heads and configured lines tailored to specific film widths and throughput requirements. For technical teams, evaluating die head design and extruder compatibility is the first decision; the following subsections explain co-extrusion mechanics and polymer choices that define multilayer film properties.

Co-extrusion technology uses multiple extruders that each melt and meter a distinct polymer formulation, delivering those melts into a multi-manifold die head that stacks the layers concentrically before inflation into a bubble. The die head design determines layer uniformity and achievable layer counts—simpler tandem heads produce ABA-type 3-layer constructions while more complex gear or spiral mandrel heads enable stable 5- and 7-layer arrangements with thin functional layers. Layer sequencing is chosen to place barrier or tie layers centrally, with outer skins providing mechanical protection and the innermost layer ensuring sealability; this sequencing reduces the need for secondary lamination. Practical examples include ABA structures for cost-effective strength and ABC constructions that include a thin EVOH or adhesive layer sandwiched inside to provide oxygen-barrier performance without sacrificing surface properties.

The intricate process of designing these multi-manifold die heads is crucial for achieving optimal film properties, as highlighted by research into advanced extrusion die optimization.

Advanced Extrusion Die Design & Optimization for Plastic Films

This report deals with design of dies used in the plastic extrusion industry. The design methodology for extrusion dies has evolved over the years with advancement of computing technology. However, the design process is still heavily dependent on the experience of the die designer, and hence is still considered to be more of an art than science. In this report, a proprietary optimization code for extrusion dies, .developed by Plastic Flow LLC, was tested and shown to be advantageous over manual methods of flow balancing which are still being applied in the industry.

Design features and optimization of profile extrusion dies, 2016

Different die head geometries and melt channeling strategies influence layer homogeneity and melt temperature management, making die selection and thermal profiling critical aspects of high-performance multilayer lines. The next subsection explains which polymer families are commonly used to build these layered films and why their rheological compatibilities matter for stable co-extrusion.

Common polymers used in multi-layer blown film production include LDPE, LLDPE, HDPE, PP, and EVA, each selected for properties such as toughness, elongation, sealing window, and processability. LLDPE and LDPE are frequently used in skin and core layers for good toughness and drawdown; EVA or modified polyolefins are chosen as sealant layers for low temperature heat-sealability, while HDPE and PP provide stiffness and high-temperature performance where required. Processing considerations include melt temperature windows, melt flow index compatibility, and potential need for tie layers or compatibilizers when blending polyolefins with barrier materials like EVOH or nylons; mismatch in viscosity or thermal profiles can lead to layer distortion or processing instability. Understanding these material choices and compatibilization strategies informs extruder screw selection, barrel heating zones, and the need for gravimetric dosing to maintain layer ratios precisely.

To clarify typical layer roles and properties, the table below summarises common layer assignments and their functional attributes.

Different polymer layers contribute distinct functions within a multi-layer film and must be selected to meet performance targets.

| Layer Role | Typical Polymers | Primary Functional Value |

|---|---|---|

| Outer skin | LLDPE, LDPE, HDPE | Mechanical protection, printability, abrasion resistance |

| Core layer | LLDPE, HDPE, recycled blends | Puncture resistance, tensile strength, cost-structure |

| Barrier layer | EVOH, PA (nylon) | Oxygen and aroma barrier to extend shelf life |

| Sealant/inner | EVA, LDPE, modified PE | Low-temperature heat sealability and good hot-tack |

| Tie/adhesive | Modified PE, tie-resins | Interlayer adhesion between incompatible polymers |

High-performance blown film extruders integrate precision metering, advanced cooling, and automation to deliver consistent gauge, high line speeds, and reduced scrap—features that directly lower cost per kilogram of film produced. Key features include internal bubble cooling (IBC) for tighter optical and thickness control, automatic thickness control systems that use profilometry and closed-loop feedback to reduce gauge variation, and gravimetric dosing systems that precisely weigh and feed resins and masterbatches for repeatable layer ratios. Automation through PLCs and servo-driven winders minimises downtime during roll changes and improves roll quality, while energy-efficient drives and modern screw/barrel designs reduce specific energy consumption. Understanding how these elements interact is essential when comparing lines: IBC stabilises the cooling profile and bubble shape, gravimetric dosing limits material variance, and automatic winders ensure consistent roll formation for downstream converting.

Below is a comparison table that maps key features to operational benefits, offering quantitative or qualitative impact estimates to aid purchasing decisions.

High-performance features translate into measurable benefits that affect yield, quality, and operating cost.

| Feature | Benefit | Typical Impact |

|---|---|---|

| Internal Bubble Cooling (IBC) | Stabilises film cooling and reduces gauge variation | Lower scrap, improved clarity |

| Automatic Thickness Control | Real-time gauge feedback and corrective control | ± tolerance reduction, fewer rejects |

| Gravimetric Dosing | Accurate resin/blend feed by weight | Material savings, consistent layer ratio |

| Automatic Winder | Precise roll tension and lay-flat winding | Faster job changeovers, improved roll quality |

| Energy-efficient Drives | Reduced motor energy draw and heat loss | Lower kWh/kg produced |

Internal Bubble Cooling (IBC) uses chilled air or controlled internal flow to homogenise the bubble’s temperature profile, which improves film clarity, reduces surface irregularities, and tightens thickness distribution across the web. Automatic thickness control systems couple non-contact gauges or laser/infrared profilometers with PLCs to adjust haul-off speed or die lip gap dynamically, reducing gauge bands and off-spec production. The combined effect of IBC plus closed-loop thickness control is a substantial reduction in scrap rates and improved conversion yields because downstream printing and bag-making processes receive consistent, dimensionally stable film. These systems also support faster ramp-up to target gauge after web breaks or recipe changes, shortening production downtime and increasing effective throughput.

The next subsection explains how gravimetric dosing and advanced winding systems support line-level efficiency and cost control.

Gravimetric dosing measures and controls resin and additive feed rates by weight, delivering precise layer compositions and minimising raw material overuse; compared to volumetric feeders, gravimetric systems typically reduce variance and can decrease material waste and off-spec runs. Automatic winders with programmable tension control and roll-build algorithms maintain consistent roll diameter and lay-flat characteristics, reducing manual handling and speeding roll changes—this translates to higher effective line uptime and more predictable downstream converting. Together, these systems reduce labour touchpoints and improve product traceability through consistent batch recipes, especially important when using recycled content or colour masterbatches. Suppliers often quantify improvements as percentage reductions in scrap or increases in net output per shift, and buyers should request case metrics or trial data when evaluating claims.

To illustrate how these features affect specification choices, the next section compares multi-layer configurations and their primary applications.

Multi layer blown film systems are commonly configured as 3-layer, 5-layer, or 7-layer lines, each offering trade-offs between cost, performance, and production complexity. Three-layer machines provide cost-effective strength and simple co-extrusion control suitable for shopping bags, refuse sacks, and basic liner films. Five-layer systems enable the inclusion of thin functional or tie layers to balance mechanical properties with barrier performance for applications like food packaging, courier sacks and shrink films. Seven-layer solutions allow ultra-thin barrier or adhesive layers sandwiched between protective skins, delivering the highest performance for specialised packaging where oxygen/moisture control or reduced lamination is required. Below is a compact comparison designed to capture these choices for quick buyer reference and featured-snippet style clarity.

Purchase decisions hinge on application needs: cost-sensitive consumer films often use 3-layer lines, while food-grade and high-barrier applications benefit from 5- or 7-layer constructions to avoid secondary laminations.

| Layer Configuration | Primary Applications | Typical Film Properties / Advantages |

|---|---|---|

| 3-layer (ABA/ABC) | Shopping bags, refuse bags, liners | Cost-effective strength, easy conversion |

| 5-layer | Food packaging, courier films, agricultural films | Balanced barrier and mechanical performance |

| 7-layer | High-barrier packaging, specialised films | Enhanced barrier, thin functional layers, fewer laminations |

Three-layer blown film machines are often configured as ABA or ABC constructions to combine an engineered core with protective skins; this structure offers a balance of mechanical strength and surface properties at lower capital and operating complexity. Common products produced on 3-layer lines include retail carrier bags, refuse sacks, pallet wrap, and industrial liners where high barrier performance is not essential but tensile strength and tear resistance are required. These machines are typically simpler to operate and maintain, making them attractive for converters needing reliable throughput and easy recipe changes; they are also straightforward to integrate with plastic bag making machines for inline conversion. For buyers focused on value, 3-layer lines often provide the quickest payback while enabling upgrades such as gravimetric dosing or thicker cores for puncture resistance.

Understanding 3-layer economics leads naturally to why more layers are chosen when barrier or shelf-life becomes critical.

Five-layer and seven-layer systems place thin barrier or tie layers centrally where they contribute disproportionately to film performance without large increases in resin cost, enabling oxygen and moisture control through materials like EVOH or PA. In a 5-layer construction, a central barrier layer protected by inner and outer polyolefin skins can extend shelf life and reduce the need for adhesive laminations, while 7-layer systems allow even thinner functional layers and complex tie-layer strategies to combine incompatible polymers effectively. The commercial benefits include reduced material usage for equivalent barrier performance, elimination of secondary laminating steps in many cases, and improved hot-tack or seal integrity through dedicated sealant layers. These options increase equipment complexity and require tighter process control, but they can unlock higher-margin packaging products that command premium pricing.

Choosing between configurations depends on product specifications, regulatory packaging requirements, and cost trade-offs between line complexity and finished goods value.

Multi layer blown film extrusion supports sustainable packaging by enabling the selective use of recycled content in non-critical layers, lightweighting through engineered layer placement, and energy-saving process features that lower the carbon intensity per kilogram of film produced. By placing recyclate in a core layer while retaining virgin sealant skins, co-extrusion preserves surface properties and seal performance while increasing circularity. Lightweighting strategies replace thick homogeneous films with multi-layer constructions that maintain strength at lower overall gauge, reducing resin usage and logistics emissions. Process technologies such as IBC, energy-efficient drives, and optimized screw/barrel designs reduce specific energy consumption, further decreasing operating carbon footprint while improving economics.

These sustainability paths require careful material selection and compatibilization; the next subsections outline recyclate strategies and energy-efficiency features buyers should request.

Using recycled materials and biodegradable layers offers lower embodied carbon and the ability to meet regulatory or customer sustainability targets, but success depends on processability and final product quality. Typical practical strategies place up to moderate percentages of post-consumer recyclate in inner core layers where contamination risk is lower while keeping outer skins and sealant layers virgin or compatibilized to preserve printability and sealing. Compatibilizers or tie layers may be required to blend polyolefin recyclates with virgin polymers, and buyers should expect validation of mechanical properties and barrier performance when recyclates are used. In practice, specifying maximum recyclate content, testing through accelerated ageing, and documenting supplier quality will help converters achieve sustainability without sacrificing performance.

Scaling recyclate use naturally leads to process-focused energy savings, which are covered in the next subsection.

Energy efficiency features such as modern AC inverter drives, optimised screw geometries, and internal bubble cooling reduce electricity consumption per kilogram of film produced and improve thermal management across the line. Industry benchmarks typically show that retrofitting or selecting lines with high-efficiency drives and process recovery systems can lower specific energy use by a measurable percentage versus older equipment, translating directly into reduced operating cost and lower CO2-equivalent emissions per tonne. Buyers should request kWh/kg figures from suppliers and consider total cost of ownership metrics that include energy, scrap, and maintenance; these figures make the business case for slightly higher capital expenditure on more efficient systems. Combining energy-efficient hardware with operational best practices—such as scheduled screw cleaning and reduced idle times—maximises savings and supports sustainable production goals.

The next section explains why local representation and service are important when procuring and commissioning complex co-extrusion lines.

Plastic Bag Machine South Africa operates as a local representative for Kingdom Machinery Co., Ltd. and offers access to multi-layer blown film extrusion machines, plastic bag making machines, flexo printing machines, and plastic recycling machines while emphasising simple operation and perfect performance. Their local proposition highlights easy maintenance and timely after-sales service along with a market presence across Gqeberha, Soweto, Cape Town, and Johannesburg to support installation and spare parts logistics. The company positions its offering as cost-effective machinery providing low investment with high quality and durability, plus flexible customization for factory layouts, which can be especially valuable for converters planning line integration. For buyers, this local representation shortens response time for technical support and provides a practical contact point for specifying die heads, IBC systems, and downstream winders.

The following table summarises core value propositions and how they benefit South African buyers.

Below is a concise mapping of vendor value propositions to buyer benefits to support procurement conversations.

| Proposition | Supplier Offering | Buyer Benefit |

|---|---|---|

| Simple operation and perfect performance | Pre-configured machine controls and user-friendly HMI | Shorter operator training, consistent output |

| Easy maintenance and timely after-sales service | Local support network in major cities | Reduced downtime, local spare parts availability |

| Cost-effective machinery | Competitive equipment options, flexible layouts | Lower CAPEX and predictable OPEX |

| Flexible customization | Tailored line layouts and layer counts | Fit-to-factory installations and product-specific specs |

Plastic Bag Machine South Africa emphasises flexible customization for factory layouts, enabling specification of layer counts, film widths, and integration with plastic bag making or flexo printing equipment. After-sales offerings include access to spare parts, technical service coordination, and commissioning support through their local presence; this service package helps maintain uptime and ensures the line runs to design parameters. Typical customization examples include adapting die heads for narrow web or wide web production, adding gravimetric dosing modules for tight recipe control, and specifying automatic winders with particular roll-build algorithms for downstream converting. Buyers should request service-level details and spare-parts lead-time commitments during procurement conversations to ensure operational continuity.

A market presence in Johannesburg, Cape Town, and Gqeberha reduces logistics friction for installation, spare parts delivery, and on-site commissioning, and it shortens travel time for field engineers attending to line issues. Proximity to major manufacturing hubs translates to faster spare-parts turnaround and more predictable scheduling for preventative maintenance visits, minimising downtime and improving supply chain reliability. Local representation also facilitates demonstrations, pilot trials, and plant visits so technical teams can validate film properties and production metrics before committing to full-scale installations. These benefits support a smoother transition from purchase to production and provide converters with a practical channel for ongoing technical dialogue and iterative upgrades.

Prospective buyers frequently ask about return on investment, maintenance schedules, installation timelines, and typical throughput—these concerns drive specification choices and supplier comparisons. Calculating ROI requires combining equipment CAPEX with expected operating savings from reduced scrap, material savings through gravimetric dosing, and energy reductions; including conservative estimates for downtime and maintenance ensures realistic payback projections. Maintenance and serviceability affect long-term performance, so buyers should prioritise accessible wear parts, clear maintenance intervals, and local support arrangements. The following subsections answer two of the most common technical and commercial questions succinctly to assist procurement teams in building evaluation criteria.

ROI for blown film lines is calculated by comparing the total cost of ownership—capital cost plus operating expenses—with the net revenue or cost savings generated over a payback period; key inputs include line throughput (kg/hr), yield (net usable film per kg input), scrap rate, material cost per kg, energy cost per kWh, and labour costs. A simple ROI framework begins with estimating incremental benefits from features: gravimetric dosing might reduce resin variance and give a measurable percentage reduction in material cost, automatic thickness control reduces scrap rates, and efficient drives lower energy per kg—these savings roll into annual OPEX reductions which are compared to CAPEX to determine payback years. Buyers should request supplier-provided case studies or performance guarantees showing kWh/kg and scrap reduction figures and then run scenario analyses using conservative estimates. This approach produces a defensible payback estimate to support investment decisions.

Clarifying ROI connects directly to maintainability and uptime, which are covered in the next subsection.

Consistent preventative maintenance is essential for long-term performance and includes daily checks on die and nip cooling, weekly inspection of screws and barrel wear, monthly calibration of thickness gauges, and scheduled replacement of common wear items like cutter blades, bearings, and heater bands. Keeping an inventory of critical spare parts—such as die seals, heater cartridges, and winding components—reduces downtime when failures occur and supports rapid restoration to production. Recommended practices include documented shift handovers, torque-checked fasteners during monthly maintenance, and planned screw cleaning intervals to prevent polymer build-up; these steps combined with local after-sales support ensure consistent output. Implementing a preventative maintenance schedule and tracking key performance indicators like mean time between failures (MTBF) helps manufacturers move from reactive to proactive maintenance strategies and protects equipment ROI.

For sales inquiries and to request a tailored equipment specification or quote, contact Plastic Bag Machine South Africa to arrange technical consultations, demonstrations, or quotation requests with local service support and line configuration options.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.