Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Single layer blown film extruders convert molten polyethylene into continuous tubular film by extruding polymer through an annular die, inflating a bubble and cooling it to form finished film suitable for bags, liners and other flexible packaging. This guide explains how single layer blown film extrusion works, what key components and process variables determine film quality, and why single-layer lines remain a cost-effective choice for many South African manufacturers seeking predictable performance and lower capital outlay. Manufacturers will learn how to evaluate machine features, estimate price ranges and return on investment, and match downstream equipment like bag-making and recycling systems to ensure a reliable production workflow. Practical sections cover energy and maintenance strategies that reduce operating costs, troubleshooting common film defects, and a buyer’s checklist for supplier evaluation and customization. The article also highlights related machines commonly paired with blown film lines so readers can plan integrated, efficient production setups.

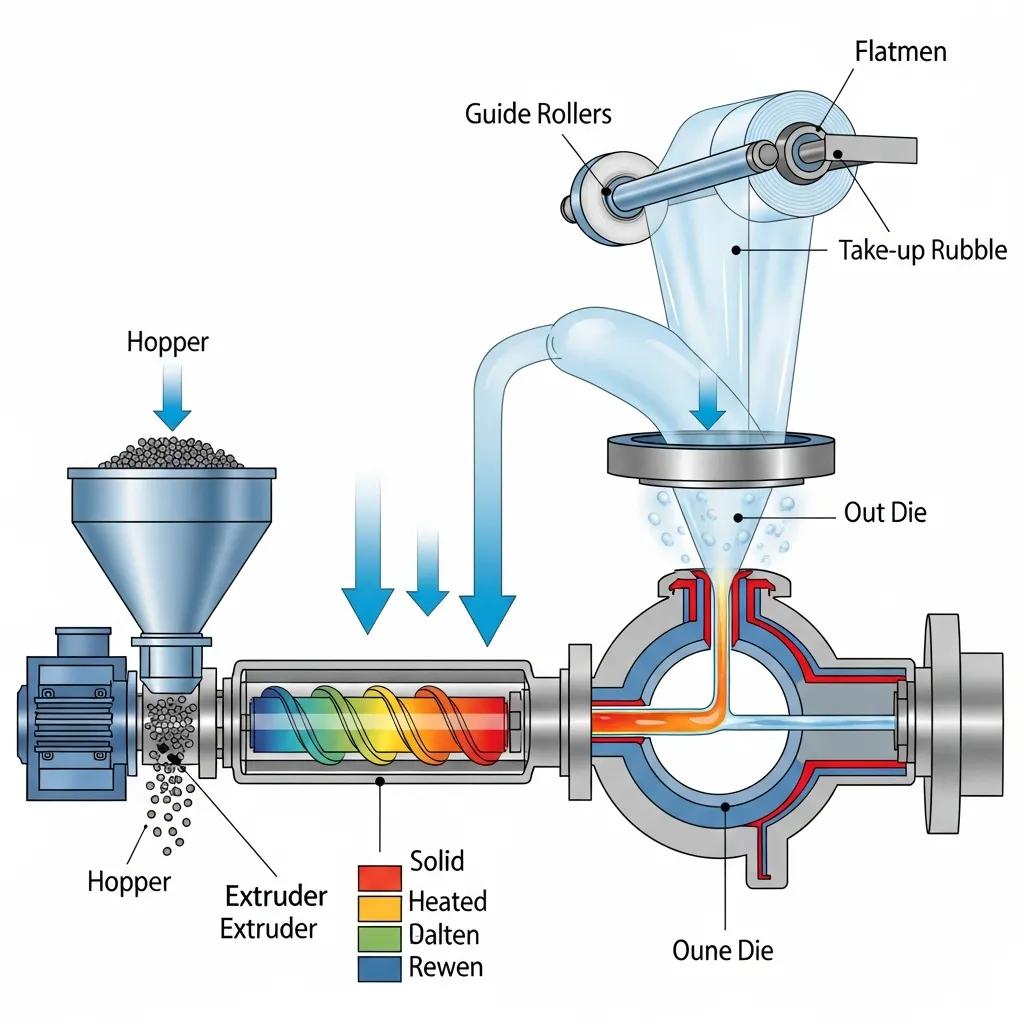

Single layer blown film extruders are film extrusion equipment that melt polymer resin and form a continuous tubular film through an annular die, using inflation and controlled cooling to set film gauge and properties. The mechanism combines extrusion pressure, die design, cooling rate and haul-off speed to produce film with targeted thickness, strength and clarity; the result is a versatile film suitable for HDPE, LDPE and LLDPE formulations. Understanding the basic flow from melt to wound roll is essential for choosing and operating a cost-efficient single layer film system, and it sets up practical considerations for component selection and process control discussed below.

Further research emphasizes the importance of understanding the entire extrusion train for optimizing LLDPE blown film production.

LLDPE Blown Film Extrusion: Process & Optimization

LLDPE blown film line, as described in general terms below. into an extruder along with plastic to produce rolls of film. The of the extrusion train to make a pound of film.

Blown Film Extrusion Optimization-Control and Screws, 1991

The blown film extrusion process begins with resin melting in the extruder screw, followed by pressurised flow through an annular die and controlled inflation to form a bubble. Critical process variables include melt temperature, blow-up ratio, frost line height and haul-off speed, all of which influence film thickness control, mechanical properties and optical finish. Properly managing these variables reduces film gauge variation and scrap, and leads into the next topic: the mechanical and control components that make those adjustments reliable.

The fundamental principles of the blown film process, whether single or multi-layered, rely on precise control of these parameters.

Single Layer Blown Film: Process Parameters

blown film process can be a single layer (monolayer) film structure or contain multiple layers. This section will describe some of the process parameters.

Blown film processing, 2017

A single layer blown film line comprises several ergonomic parts—extruder screw and barrel, die head, cooling ring, haul-off, winder and control panel—each affecting throughput and film quality. The extruder screw size and L/D ratio control melting and output; the die head design determines flow uniformity and bubble stability; the cooling ring and air management set the frost line and orientation. Below is a compact EAV-style table summarising typical component specs to help buyers compare machines quickly.

Introductory note: the table lists common component configurations and typical ranges to aid specification interpretation.

| Component | Typical Specification | Typical Range / Example |

|---|---|---|

| Extruder screw | Diameter / L:D | 45–120 mm; L/D 24:1–30:1 |

| Die head | Type / lip gap | Annular die; adjustable gap 0.5–3.0 mm |

| Cooling ring | Air flow control | Adjustable flow; uniform ring cooling |

| Haul-off | Drive type / speed | Servo or VFD; 0–60 m/min |

| Winder | Type / roll dia. | Surface/contact winder; up to 600 mm roll diameter |

This table clarifies how component choices affect capacity, film gauge control and capital cost, and prepares the reader to evaluate models and suppliers in the next section.

Choosing a cost-effective single layer blown film extruder requires balancing upfront capital, energy consumption, ease of maintenance and the ability to meet product specifications. Focus on key features that reduce operating cost and downtime, verify supplier after-sales support and spare parts availability, and confirm that automation and control options align with your production targets. The following checklist distils essential evaluation criteria into actionable items for procurement teams and plant managers.

When evaluating suppliers, consider warranty terms, local technical support, lead times and evidence of quality control; these factors materially influence total cost of ownership. In South Africa, distributor presence and capability to customise a line to local power and space constraints can reduce installation delays and commissioning expense, which is covered in the supplier evaluation checklist that follows.

Energy-efficient drives: Look for VFDs and efficient motors that lower kWh/kg film.

Serviceable screw and die designs: Simple maintenance reduces downtime and spare-part costs.

Robust automation: Closed-loop thickness control and recipe storage improve yield consistency.

Local support and spare parts: Verify how quickly critical parts can be sourced locally.

Flexible customization: Ability to match motor, gearbox and winder choices to product needs.

This checklist helps buyers prioritise technical attributes that yield long-term savings. Next we present a short guidance on supplier evaluation and customization questions to ask potential vendors.

Identify features that cut energy use and simplify maintenance while delivering consistent film gauge and strength. Efficient screw geometry and a well-designed die head reduce melt pressure and power consumption; automation such as closed-loop gauge control reduces operator dependency and scrap; durable bearings and accessible components shorten repair times. Selecting appropriate winder types and roll diameters for your bag-making downstream reduces rework and manual handling needs. These practical choices lead naturally into assessing suppliers for warranty, training and delivery capability.

When assessing vendors, ask for references, case studies and a clear outline of spare-part lead times and warranty coverage, especially for electrical and mechanical drive components. Check whether the supplier can adapt equipment to local electrical standards and provide operator training and commissioning support; evidence of final inspection and R&D expertise suggests reliable product quality. Plastic Bag Machine South Africa operates as a representative and distributor for Kingdom Machinery Co., Ltd., and offers one-stop customised products, experienced R&D engineers and a final inspection process; buyers can request tailored configuration and quotes based on capacity and automation needs. This supplier insight transitions into price expectations and financing considerations in the following section.

Typical price ranges for single layer blown film machines depend on output capacity, level of automation, and whether the line includes high-spec die heads or advanced winders; a concise summary helps set expectations early in procurement. Lower-capacity, semi-automatic single layer machines aimed at small manufacturers generally cost substantially less than industrial, fully automated lines, while higher-spec models with energy-efficient drives and advanced control systems command premium pricing. Key price drivers include motor and gearbox sizing, die head precision, automation level and any import logistics or installation work required for the South African market.

Below is a compact EAV comparison table to compare representative model classes by capacity and indicative price brackets to help buyers frame budgets.

Introductory note: the table below maps typical model categories to output and indicative price ranges to aid procurement planning.

| Model Class | Output Capacity | Indicative Price Range (ZAR-equivalent) |

|---|---|---|

| Small benchtop / lab line | <50 kg/day | Entry-level price range |

| Small production single layer | 50–300 kg/day | Lower-mid budget range |

| Industrial single layer line | 300–1500+ kg/day | Mid-to-high budget range |

This comparison helps teams prioritise required throughput and estimate total procurement costs. The next subsection explains the factors that most affect price and how financing or ROI calculations can validate investment.

Price is influenced by equipment capacity, customization, automation level, and logistics including import duties and installation. Higher output machines require larger screws, more powerful motors and sturdier winders, all increasing cost; advanced control systems and servo drives add capital but reduce operating expenses. Local distributor support and available spare part stocks also affect landed cost and time-to-production, making supplier selection as important as the headline equipment price. Understanding these drivers prepares manufacturers to model working capital needs and negotiate realistic lead times and installation packages.

Financing options include supplier offers, leasing and traditional bank finance; each route affects monthly cashflow and payback timing. A simple ROI approach compares incremental gross margin from produced film against monthly equipment finance and operating costs, using conservative yield and energy assumptions to estimate payback period. Manufacturers should include energy savings from efficient motors and reduced labour from automation when modelling ROI; a short payback strengthens a procurement case. For a tailored price range and financing guidance matched to required capacity and configuration, buyers may request a tailored quote from Plastic Bag Machine South Africa to get accurate figures and lead-time estimates.

Single layer film extrusion provides manufacturers with lower capital expenditure, simpler operation and easier maintenance compared with multilayer lines while still covering many common film applications. The straightforward construction reduces spare-part variety and technician training time, enabling faster start-up and simpler troubleshooting which benefits small and medium-sized operations focused on bags, liners and agricultural film. The next paragraphs explore energy and operational cost savings and the product versatility that make single-layer lines attractive for many producers.

Single layer lines can achieve meaningful energy and labour savings when configured with efficient screws and automation, and they integrate well with common downstream bag-making equipment; this combination supports predictable margins and quicker ROI as discussed earlier.

Energy efficiency in single layer blown film machines arises from optimized screw geometry, properly sized motors and effective thermal management to minimise heat losses. Incorporating VFD-driven motors and modern control panels reduces idle power draw, and operational practices—such as optimised start/stop sequences and reduced scrap—further lower kWh per kg of film. These measures result in lower operating cost per roll and improve payback timelines when compared to less efficient or older lines. Improved energy performance also makes single-layer lines more attractive where energy pricing and reliability vary, leading naturally into how single layer versatility affects application choice.

Single layer extruders can produce HDPE, LDPE and LLDPE films across a range of thicknesses suitable for shopping bags, refuse sacks, pallet covers and agricultural films, with trade-offs between clarity, strength and stretch depending on resin and process settings. For many bag-making and packaging uses, single-layer film meets strength and barrier requirements at a lower cost than multilayer constructions, especially when additives or co-extrusion are not required. When multilayer properties are necessary—for example higher barrier or sealability—alternatives should be evaluated, but for volume commodity products single-layer remains an efficient choice. After outlining these benefits, we present practical maintenance and operational guidance to sustain performance.

Research further explores how extrusion parameters specifically impact the properties of LLDPE-based monolayer films, contrasting them with multilayer structures.

Monolayer Blown Film Properties: Extrusion Parameters

In this work we investigated the effect of extrusion process parameters single-site PE in monolayer films and a five-layer coextruded blown film structure consisting of alternating layers

LLDPE‐based mono‐and multilayer blown films: Effect of processing parameters on properties, MA Huneault, 2005

Integration note: Plastic Bag Machine South Africa represents Kingdom Machinery Co., Ltd. and supplies blown film extrusion equipment and complementary production lines. Their value propositions include one-stop customised products, experienced R&D engineers, 100 percent final inspection, competitive pricing from large-scale production and fast delivery; buyers seeking quotes tailored to production targets can request a personalised estimate from the distributor. This supplier information complements the technical benefits above and leads into maintenance and operation best practices.

Consistent operation and preventative maintenance are essential to preserve film quality and minimise unplanned downtime; a defined daily and periodic maintenance routine keeps bearings, heaters, gearbox and control systems within specification. Operators should run daily checks on melt temperature stability, vacuum and air flows in cooling systems, winding tension and electrical drives, and should maintain a log to spot trends. Routine preventive actions reduce the likelihood of film breaks and gauge variation and link directly to earlier points about energy efficiency and ROI.

Below is a practical maintenance schedule table that maps tasks to frequency and notes for operations teams to implement.

Maintenance schedule note: the table presents common preventive tasks, suggested frequency and practical notes for shop-floor implementation.

| Task | Frequency | Notes / Time |

|---|---|---|

| Check screw/barrel wear | Monthly | Inspect for pitting; schedule rework if >10% wear |

| Clean die and calibrate gap | Weekly | Prevent frozen spots and gauge variation |

| Check cooling ring and air filters | Daily | Ensure uniform cooling and frost line stability |

| Inspect bearings/gearbox oil | Monthly | Top-up or change per manufacturer guidance |

This schedule helps operations teams plan spare parts and maintenance windows, reducing production interruptions and supporting predictable output. The next subsection provides a troubleshooting guide for common film defects and first-line corrective actions.

Daily procedures should include equipment pre-start checks, verification of recipe settings and a quick visual inspection of the bubble and winding quality. Preventative maintenance tasks such as cleaning the die face, checking heater band continuity, monitoring gearbox oil levels and confirming vacuum lines are unobstructed should be performed on consistent schedules. Maintain a small stock of critical spares—heater bands, thermocouples, bearing sets and die seals—to avoid extended outages. These daily habits reduce recurring faults and prepare operators to diagnose common issues described next.

Common problems include bubble instability, film gauge variation and film breaks; each symptom has a short list of likely causes and first-fix steps that operators can apply immediately. For example, bubble instability often stems from uneven cooling or inconsistent extrusion pressure and can be mitigated by checking ring airflow and melt pressure stability, while gauge variation can follow from haul-off speed fluctuations or die irregularities. If first-line fixes fail, escalate to supplier technical support with documented process logs to speed diagnosis. Proper troubleshooting reduces scrap and informs longer-term maintenance or component upgrades.

A complete film production workflow typically includes downstream bag-making machines, printing/finishing equipment and recycling systems to handle trim and post-industrial scrap. Matching capacities between blown film output and downstream bag makers is essential to avoid bottlenecks; integrating flexo printing or gusseting machines enables higher-value products and market diversification. The next subsections explain common complementary equipment types and how recycling can close material loops and improve cost and sustainability.

Bag-making machines convert film rolls into finished products using cut-and-seal, side-seal, or gusseting processes and must be matched to the film width, thickness and winding format to achieve target speeds. Capacity matching guidance: ensure film line output and winder roll diameters produce cores and roll diameters compatible with the bag maker to avoid frequent changeovers; typical coordination reduces manual handling and improves throughput. Quality control points between extruder and bag maker include consistent gauge, clean edges and correct winding tension to prevent slippage and misfeeds.

Integrating recycling equipment such as granulators, washing lines and pelletisers enables producers to reprocess trim, off-spec film and post-industrial scrap back into usable feedstock, supporting cost reduction and sustainability goals. Running recycled content on single-layer extruders requires attention to contamination control, melt-flow index adjustments and potential upgrades to filtration or venting systems; careful blending and testing secure consistent film properties. Producing circular film streams lowers raw material expenses and positions manufacturers to meet increasing sustainability expectations while maintaining efficient production.

Integration note: Plastic Bag Machine South Africa supplies a range of complementary machines for integrated film-to-bag workflows and can advise on matching blown film lines to bag-making and recycling equipment. Their distributor role and one-stop customised approach help manufacturers specify a coordinated package tailored to capacity and product mix.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.