Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Blown film extruders convert polymer resin into continuous plastic film through a controlled extrusion and bubble-inflation process, providing efficient production of bags, shrink film, and packaging film for local manufacturers. This guide explains which blown film extrusion machines are available for sale in Gqeberha, how the process works, and which machine types best match South African packaging needs, helping you evaluate throughput, layer count, and material compatibility. Many buyers in Gqeberha prioritize reliable local support, total cost of ownership, and the ability to run PE and PP resins with consistent film properties; this article maps those requirements to mono- and multi-layer architectures, typical material choices (HDPE, LDPE, LLDPE, PP), and practical inspection tips for used machines. You will find stepwise process explanations, comparative EAV tables for models and machine types, price-driver breakdowns, and a pragmatic approach to sourcing new or refurbished lines. Throughout, targeted terms like blown film extrusion, plastic film blowing machine, and blown film extruders for sale are used to help you compare options and request accurate quotes from suppliers serving Gqeberha.

The local context of blown film extrusion is further underscored by academic research conducted within South Africa, focusing on the evaluation of film blower performance.

South African Research on Film Blower Evaluation

ABSTRACT: Govender, Morgan.University of Pretoria (South Africa) ProQuest Dissertations & Theses, 2003. 30716223.

Evaluation of Commercial Purge Compounds on a Laboratory Film Blower, 2003

Blown film extruders available to manufacturers in Gqeberha range from single-screw mono-layer lines suited for basic bag production to co-extrusion multi-layer systems designed for barrier and shrink films; each class balances cost, complexity, and film performance. Buyers should evaluate machines by layer count, output (kg/h), motor power, and supported resins to align capacity with product targets such as grocery bags, carrier bags, or high-clarity shrink film. The following table compares representative new and used model families commonly supplied to South African converters, illustrating typical attributes to consider when shortlisting machines.

Representative blown film extruders available near Gqeberha

| Line Family | Layer Count / Output | Motor Power | Materials Supported |

|---|---|---|---|

| New 3-Layer Coex | 3-layer / 300 kg/h | 55 kW | PE, PP (co-extrusion for barrier or shrink) |

| New Mono 1-Layer | Mono-layer / 150 kg/h | 30 kW | LDPE, LLDPE (flexible bags, simple film) |

| Refurbished HDPE Line | 2-layer / 250 kg/h | 45 kW | HDPE, recycled PE blends |

This comparison highlights how multi-layer families increase functionality for barrier or printed film, while mono-layer lines reduce capital and maintenance complexity. Understanding these trade-offs helps you shortlist machines that meet your intended product mix and throughput targets.

New blown film extruder families sold into the South African market include mono-layer single-screw lines and co-extrusion systems for 3- to 7-layer film production that handle PE and PP grades for bags and shrink applications. New lines typically offer modern PLC controls, improved screw and die geometries for melt homogenization, and configurations that support printing and lamination downstream, which improves inline productivity and reduces manual handling. When choosing a new machine, match rated output to expected run rates and consider automation level for consistent film thickness, which affects packaging quality and scrap rates. New equipment is ideal when you need warranty-backed performance, high uptime, and the capacity to introduce multi-layer barrier structures for premium film products.

Sourcing used blown film extruders in Gqeberha commonly involves direct dealer listings, equipment brokers, and refurbished line suppliers who provide inspection reports and limited guarantees; local inspection and documented refurbishment history are essential. An inspection checklist should cover screw wear, gearbox condition, die head integrity, electrical control functionality, and availability of spare parts to ensure continued operability. When evaluating used equipment, request documentation on previous operating throughput and replacement parts installed during refurbishment, and plan for transport, reinstallation, and on-site commissioning costs. Refurbished lines can offer lower capital outlay, but ensure the seller provides transparent condition reports and a warranty or service agreement to reduce risk.

Inspection checklist for used extruders:

This checklist reduces purchasing risk and helps estimate refurbish-and-install budgets before finalizing a used-line purchase.

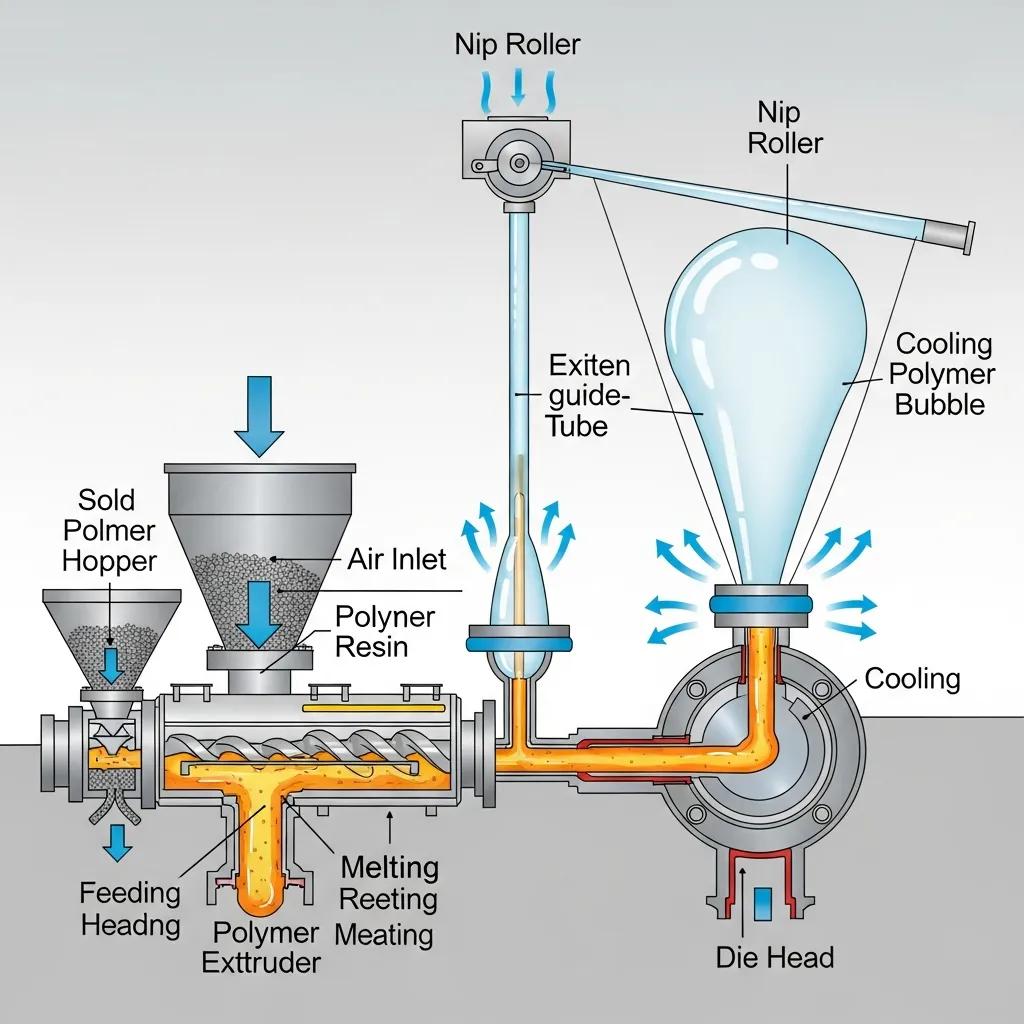

A blown film extruder melts and homogenizes polymer resin, forces the melt through an annular die to form a tubular film, inflates that film into a bubble using controlled air, cools the bubble with an air ring, collapses the bubble into flat film, and finishes by cooling and winding the roll. The core mechanism—melt generation, annular die shaping, bubble inflation, and controlled cooling—determines film thickness, clarity, and mechanical properties, so precise screw design, die configuration, and air-ring control are crucial for consistent output. Key machine meronyms include the extruder screw, die head/annular die, air ring, haul-off unit, and winder; each contributes to film uniformity and throughput. Understanding this chain of operations helps buyers assess how machine components influence final film properties and production efficiency.

The blown film extrusion process in concise steps:

Further emphasizing the fundamental steps, external research highlights the continuous nature of film extrusion and its direct application in bag manufacturing.

Blown Film Extrusion Process & Bag Production

Blown film is extruded as a continuous tube which is air cooled, collapsed, and wound onto a roll as a double layer of film. Such film, if heat sealed and perforated, makes a roll of bags. There are many factors that affect blown film extrusion.

Expert system for blown film extrusion, 1991

Blown film extrusion starts with a feed of polymer pellets that are heated and pushed forward by a rotating extruder screw; the screw’s design determines melting, homogenization, and melt pressure. The molten polymer exits through an annular die that shapes the melt into a thin tube; an air ring inflates the tube into a bubble whose diameter and cooling rate control film thickness and crystallinity. The haul-off unit pulls the bubble at a controlled speed while nip rollers collapse the bubble into flat film, which is then wound; process parameters such as frost line position, blow-up ratio, and take-off speed are adjusted to tune mechanical and optical film properties. Monitoring these stages allows converters to balance gauge control, output, and film performance for intended applications.

Common materials for blown film extrusion include low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and polypropylene (PP), each offering different film stiffness, sealability, and barrier attributes. LDPE and LLDPE are favored for flexible bags and films due to their softness and sealability, while HDPE provides stiffness and puncture resistance for heavier sacks and carrier bags; PP can be used for clearer, higher-temperature applications like shrink film with appropriate adjustments. Recycled resin blends are increasingly used to reduce cost and environmental impact, but they require careful melt management and potential equipment modifications to handle contaminants and inconsistent melt indices. Matching resin choice to product performance, processing temperature, and downstream printing or lamination needs is essential for consistent production.

Academic studies further delve into how the molecular structure and processing parameters of various polyethylene types directly influence the final properties of blown films.

Polyethylene Blown Film Properties & Process Parameters

Molecular orientation and structure development during film blowing have a major effect on mechanical and physical properties of polyethylene films. In this work the structures and morphology of three different polyethylene blown films; linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), and high density polyethylene (HDPE) were studied.

Investigation on the structure and properties of different PE blown films, A Ajji, 2007

Selecting the right blown film extruder for South African packaging depends on product type, production scale, and material choice; small-scale converters may prefer mono-layer mono-screw lines for simplicity, while larger operations producing barrier or printed film benefit from multi-layer co-extrusion to combine functionality and printability. Multi-layer systems enable tailored layer structures—such as a recycled core, a barrier middle layer, and a heat-seal outer layer—to meet product requirements without compromising performance. Scale considerations also govern support systems: larger lines typically require more robust haul-off and winding units, closed-loop thickness control, and greater spare-parts planning.

Machine types mapped to South African packaging needs

| Type | Best for | Value |

|---|---|---|

| Mono-layer | Simple flexible bags, low-cost film | Lower capital cost, easier maintenance |

| 3-layer co-extrusion | Shrink film, printed film, improved mechanical properties | Balanced performance and investment |

| Multi-layer (5+ layers) | Barrier films, high-performance packaging | Higher capability, increased complexity |

This mapping shows mono-layer lines suit basic bag makers, while multi-layer co-extrusion addresses higher-value packaging demands where barrier, printability, or mechanical profiles are required.

Mono-layer blown film extruders use a single melt stream and are simpler to operate, cost less to buy and maintain, and typically consume fewer spare parts, which makes them attractive for basic bag manufacturing and lower complexity operations. By contrast, multi-layer co-extrusion lines combine several extruders and a feedblock or die to create layered film structures that deliver enhanced barrier properties, improved mechanical strength, and better printability; these advantages come with higher capital investment and more complex maintenance regimes. Deciding between the two depends on product requirements—if barrier, seal strength, or environmental performance is critical, multi-layer lines are often justified; for commodity carrier bags and low-thickness film, mono-layer machines offer reliable, lower-cost production.

Key operational trade-offs between mono- and multi-layer systems:

These trade-offs guide whether a converter prioritizes low TCO or advanced film functionality for market differentiation.

HDPE-focused blown film lines are set up to process higher-density resins at slightly different temperatures and screw geometry to achieve films with stiffness, toughness, and puncture resistance preferred for heavy-duty sacks and rigid-feeling carrier bags. LDPE and LLDPE lines are tuned for lower melt viscosity and deliver films with greater flexibility, sealability, and softer hand—qualities important for grocery bags, cling film, and flexible packaging. Processing parameters differ: HDPE typically requires higher shear and cooling strategies to control crystallization, while LDPE benefits from controlled cooling and lower blow-up ratios for elasticity. Choosing between HDPE and LDPE lines depends on end-use performance requirements, recyclability goals, and downstream converting processes such as printing or lamination.

Plastic Bag Machine South Africa operates as Kingdom Machinery Co., Ltd., and supplies blown film extrusion equipment alongside a suite of complementary machines for plastic production, positioning itself as a one-stop provider for converters in Gqeberha and the broader South African market. The company’s value proposition, as presented in supplier materials, emphasises simple operation, perfect performance, easy maintenance, timely after-sales service, a two-year warranty, strong R&D, one-stop service, robust production capacity, competitive pricing, and fast delivery. For buyers evaluating suppliers, these attributes reduce procurement friction: documented after-sales responsiveness and warranty terms can lower operational risk, while integrated offerings for printing and recycling support vertical workflows from extrusion to finished bags.

Buyers who prioritize predictable uptime and local support benefit from supplier attributes such as simple operation and easy maintenance, which reduce operator training time and spare-parts complexity. Perfect performance and robust production capacity, as stated by the supplier, indicate engineering emphasis on consistent throughput and repeatable gauge control—key for maintaining film quality across shifts. The two-year warranty and timely after-sales service help mitigate downtime exposure, while strong R&D and one-stop service enable integrated solutions that combine blown film lines with downstream printing or bag making equipment. Competitive pricing and fast delivery address procurement constraints for Gqeberha converters seeking timely ramp-up without prolonged lead times.

Local after-sales service reduces total cost of ownership by shortening response times for spare parts, simplifying installation and commissioning, and providing operator training that preserves throughput and product consistency. On-site support for installation and commissioning ensures correct alignment of the die, air ring, and haul-off settings, which directly impacts film gauge control and waste rates. Regular maintenance training and availability of critical spares prevent extended stoppages and improve mean time between failures; warranty coverage further lowers repair cost risk during early production. Prioritizing suppliers that offer local service agreements and documented service response protocols enhances long-term reliability and production planning.

Machine pricing in Gqeberha is influenced primarily by whether the line is new or used, layer count, automation level, brand and R&D backing, shipping and installation, and included spare parts or commissioning support; these drivers determine both upfront capital and lifecycle costs. Typical purchase decisions consider total landed cost—including transport, installation, training, and initial spare kits—rather than nominal machine price alone. The table below clarifies how condition and configuration influence price drivers to help you frame realistic quote requests.

Price drivers for blown film extruders in Gqeberha

| Condition | Price drivers | Value |

|---|---|---|

| New | Brand, layer count, automation, warranty, export packing | Higher capital cost, lower near-term risk |

| Used / Refurbished | Age, refurbishment quality, spare parts installed, inspection results | Lower purchase price, variable refurbishment cost |

| Extras | Installation, training, spare kits, control upgrades | Add to landed cost but reduce startup risk |

Typical purchase decisions consider total landed cost—including transport, installation, training, and initial spare kits—rather than nominal machine price alone. The table below clarifies how condition and configuration influence price drivers to help you frame realistic quote requests.

Several concrete factors drive price and lifecycle cost for blown film lines: the machine brand and its engineering pedigree; number of layers and extruders in co-extrusion systems; level of automation and closed-loop gauge controls; condition and refurbishment level for used lines; inclusion of downstream equipment like winders and printing stations; and logistical costs for transport and on-site commissioning. Additionally, warranty length and local after-sales coverage reduce predicted repair costs and thus affect the effective purchase decision. Evaluating machines by total cost of ownership—capital plus expected maintenance and downtime—enables a comparative purchase decision rather than focusing solely on sticker price.

Primary price drivers explained:

Understanding each driver helps frame targeted RFQs that produce comparable offers.

Competitive pricing channels include direct manufacturer quotations for new lines, local dealers offering stock or refurbished machines, and used-equipment marketplaces that list lines for immediate purchase; trade events and industry networks can also surface timely opportunities. When comparing offers, require itemized quotes that separate machine price, packing, shipping, customs handling, on-site installation, training, and spare parts to evaluate total landed cost. Negotiate service terms and warranty conditions and consider requesting trial runs or factory acceptance tests where feasible to confirm performance before shipment. For a localized quote or demonstration tailored to your production needs, contact Plastic Bag Machine South Africa (operating as Kingdom Machinery Co., Ltd.) to discuss available blown film extrusion lines and on-site service options.

For manufacturers exploring integrated production lines or converting to higher-value films, Plastic Bag Machine South Africa also supports complementary equipment including plastic bag making machines, flexo printing machine, and plastic recycling machine—contact the supplier to request quotes and arrange demos or site visits for detailed evaluation of blown film extruders and associated converting equipment.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.