Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

High-speed t-shirt bag making machines are industrial systems that convert rolled film into finished t-shirt (vest) bags at high throughput, designed for manufacturers, converters, and packaging operations seeking reliable volume production. This guide explains how modern automatic t-shirt bag making machines work, highlights the technical features that drive speed and quality, compares material compatibility including HDPE, LDPE and biodegradable blends, and outlines buying and ROI considerations specific to South Africa. Manufacturers facing rising demand, tighter retailer specifications, and pressure to offer eco-friendly options will find concrete guidance on machine selection, production planning, and how automation affects unit costs. The article maps key machine features, material handling and process settings, business benefits for South African operations, technical specifications and model comparisons, sourcing options within the country, and pricing/ROI considerations to support a purchase decision. Read on to learn which machine attributes matter most for throughput, quality, and long-term operational efficiency.

Plastic Bag Machine South Africa supplies a range of plastic bag production machinery — including blown film extrusion, plastic bag making machines, flexo printing machines, and plastic recycling machines — and operates as Kingdom Machinery Co., Ltd. in South Africa. Their local presence emphasizes simple operation, easy maintenance, timely after-sales service, competitive pricing from large-scale production, and delivery speed with samples and bulk timelines noted in supplier materials. If you need equipment guidance or want to discuss production capacity for t-shirt bags, their one-stop service model can connect blown-film extrusion and bag-making options into an integrated production line. This supplier positioning clarifies how procurement and after-sales support can reduce time-to-market while keeping maintenance overhead predictable for South African manufacturers.

High-speed automatic t-shirt bag making machines combine precise motion control, fast cutting and sealing, and intelligent automation to turn film into finished bags quickly and consistently. These systems use synchronized drives and inline sensors to maintain bag length tolerance, optimize seal integrity, and reduce film waste, delivering predictable throughput and lower scrap rates. In practice, feature selection influences production speed, changeover time, and operator requirements, so understanding each core capability helps choose the right model for your output targets and product mix. The next section lists the most important features buyers should weigh when comparing high-speed t-shirt bag machines.

The five core features that define modern high-speed t-shirt bag machines are:

These features combine to increase yield and lower per-bag cost while keeping operator time predictable, and understanding servo and hot-cut mechanics leads naturally into a deeper look at those components.

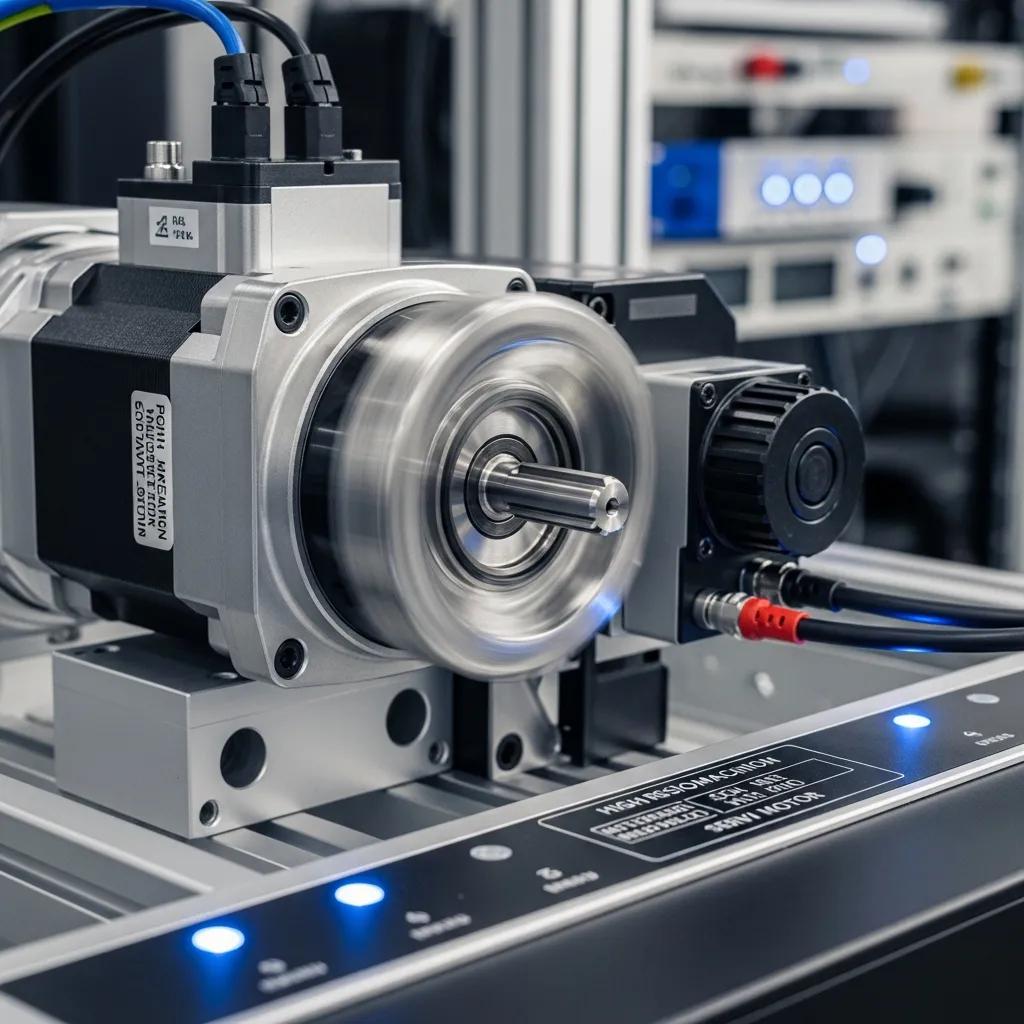

Advanced servo motor technology provides closed-loop control of film advance and cutter position, which directly translates to consistent bag length and repeatable cuts on high-speed lines. Closed-loop feedback reduces cumulative length error, lowers film waste by eliminating overfeed, and permits rapid acceleration and deceleration without losing registration, which is essential for multi-line or high-gauge film applications. Energy efficiency is another advantage: servo drives consume power only when moving, cutting overall energy use compared with constant-speed motors and reducing bearing wear from smoother motion profiles. Understanding servo synchronization clarifies why modern high-speed lines sustain throughput while maintaining tight tolerances and minimal scrap.

Servo-driven systems also simplify changeovers because position presets can be recalled from the PLC, so switching bag lengths or seam settings requires fewer manual adjustments. That quick recipe recall shortens downtime and reduces operator variability, which benefits facilities moving between sizes or materials frequently. These operational advantages lead to improved overall equipment effectiveness (OEE) and make servo technology a key investment for manufacturers targeting consistent high-speed output.

A hot-cut system melts and seals the film edges at the moment of cut, creating a fused seal that is both clean and strong compared with cold-cut, pressure-seal methods that may require secondary trimming. Hot-cut seals reduce post-processing by producing finished edges that meet retail and consumer expectations for appearance and tensile strength, especially important for printed or high-clarity films where edge finish affects perceived quality. Heat settings and knife dwell vary by material — HDPE needs different temperature and contact profiles than PLA/PBAT blends — so hot-cut systems must be adjustable and monitored to avoid film scorching or weak seals. Regular maintenance, including knife inspection and scheduled replacement, preserves seal consistency and prevents line-induced defects.

Choosing an appropriate hot-cut configuration affects aesthetic quality and throughput because faster lines require rapid knife cooling cycles and precise temperature control to avoid fused film buildup. Reliable hot-cut designs also minimize dust and particulate formation that can interfere with printing or downstream packing, improving final product reliability and brand acceptance.

High-speed t-shirt bag machines are compatible with a range of blown-film materials including HDPE, LDPE, and biodegradable polymers like PLA and PBAT blends, with each material class requiring tailored processing parameters. Compatibility depends on film melt strength, gauge, and sealing characteristics; machines with adjustable tension control, temperature-regulated sealing, and flexible handling settings can accommodate these differences while maintaining high throughput. Selecting the right film gauge and machine settings reduces scrap, prevents film deformation at high speeds, and optimizes bag durability for end-use. The table below summarizes material-specific guidance to help match material choice with machine settings and expected outcomes.

Different film types require distinct machine settings and handling approaches:

| Material | Compatibility & Required Settings | Typical Film Gauge / Recommendation |

|---|---|---|

| HDPE | High stiffness, tolerates faster line speeds; requires higher sealing force and lower dwell temp than LDPE | 10–30 µm typical for grocery/vest bags; increase tension control for clarity |

| LDPE | More flexible film that needs softer tension control and slightly higher sealing temperature to prevent wrinkles | 15–35 µm typical; adjust drive torque and web guide sensitivity |

| PLA / PBAT (biodegradable) | Sensitive to heat; requires precise temperature control and gentle handling to avoid brittleness or micro-tearing | 20–40 µm depending on blend; use lower seal temperature and controlled acceleration |

This material guidance clarifies trade-offs between speed, clarity, and seal strength and leads into specific production adjustments for each material category.

HDPE films are stiffer and generally allow faster line speeds with less tendency to wrinkle, but they need different sealing profiles and higher shear resistance in rollers to avoid slippage. LDPE offers greater flexibility and better clarity for printed bags but can require tuned tension control and slower acceleration profiles to prevent web tracking issues at high speeds. Biodegradable films such as PLA and PBAT blends demand precise thermal management and gentler mechanical handling to avoid heat-induced brittleness or seal failures, often lowering maximum practical running speed. Understanding these characteristics helps production planners set realistic throughput targets and select optional machine features like specialized rollers or enhanced cooling for biodegradable processing.

Material-driven adjustments also influence waste rates: improperly tuned systems produce wrinkles, inconsistent seals, or pinholes that increase scrap and reduce effective throughput. Investing time in material trials and establishing stable recipes in the PLC mitigates these risks and unlocks the machine’s full performance potential.

Producing biodegradable t-shirt bags opens access to eco-conscious retail segments and can help align packaging offerings with local regulations and buyer requirements, giving manufacturers a competitive advantage in sustainability-focused markets. At the machine level, handling biodegradable films often requires optional upgrades — such as refined temperature controllers, softer sealing profiles, and gentler winding systems — that preserve film integrity while maintaining acceptable throughput. While material costs for biodegradable resins tend to be higher, many buyers accept a price premium for certified compostable or home-compostable bags, which can offset raw material expense. Investing in compatible machines positions manufacturers for product diversification and improves resilience to regulatory change favoring degradable materials.

From an operational perspective, retrofittable machine options let existing t-shirt bag production lines run biodegradable films without a full-capacity rebuild, enabling gradual market testing and scaling while maintaining core production capabilities.

Adopting automated industrial t-shirt bag production lines increases throughput, reduces labor dependency, and improves product consistency, enabling South African manufacturers to meet bulk orders and retailer specifications efficiently. Automation converts variable manual tasks into repeatable mechanical processes, lowering unit labor cost, minimizing human error, and improving shift-to-shift reliability. Faster changeovers and recipe-driven PLC control let converters respond quickly to varied bag sizes, printed orders, or biodegradable requests, which supports broader product ranges and customer requirements. The following list summarizes the primary business benefits local manufacturers can expect.

Key business benefits include:

These operational gains improve margin control and customer satisfaction, which naturally leads into how automation translates into concrete operator and cost reductions.

Automation increases output by enabling continuous, high-speed operation with minimal manual intervention; a single operator can oversee multiple production lanes or machines using PLC-driven controls and automated feeders. Typical labor-to-output ratios shift favorably because machine uptime and consistent cycle times replace stop-start manual workflows, allowing fewer staff to manage higher tonnage. Automation also reduces variability-driven rejects, which lowers effective material consumption and rework expenses that would otherwise require extra labor. Training time is concentrated on a small number of operators who monitor HMI dashboards and perform scheduled maintenance, rather than relying on many operators for manual cutting, sealing, or stacking.

Because automation centralizes process control, management can plan shifts and maintenance windows precisely, reducing overtime and enabling stable production schedules that scale with demand expectations.

Consistent high-quality bag production protects brand reputation and simplifies B2B procurement because retailers and corporate buyers require reliable, specification-compliant products and predictable delivery windows. Fewer returns and reduced complaints lower the administrative and logistical costs associated with corrective shipments, while consistent bag strength, seal integrity, and print registration support retailer shelf presentation and consumer acceptance. Achieving repeatable quality also enables manufacturers to secure longer-term contracts and negotiate better pricing terms with large customers who value supply stability. Maintaining consistency requires both the right machinery (servo-control, hot-cut sealing, PLC recipes) and disciplined process controls, which together make scaling profitable and defensible.

Delivering reliable product quality thus becomes a commercial asset; it enables pricing leverage, repeat orders, and entry into higher-margin channels.

High-speed t-shirt bag machines vary by throughput (single-line vs. two-line), film gauge range, power requirements, and optional add-ons such as printing registration, bottom patching, or biodegradable-handling kits. Specifications to compare include maximum bags per minute, supported film thickness, PLC/HMI features, footprint, and required electrical power. Selecting the correct model depends on desired capacity, available floor space, and whether integration with blown-film extrusion or flexo printing is required. The table below provides an example EAV comparison to illustrate how buyers typically compare models and select the right machine for their needs.

Below is a sample model-to-spec comparison to show typical attributes buyers evaluate:

| Model | Attribute (Production Capacity, Film Thickness, Power, Footprint) | Value / Typical Range |

|---|---|---|

| Model A (single-line) | Capacity up to 300 bags/min; film 10–30 µm; power 7–12 kW; compact footprint | Good for medium-volume shops with limited floor space |

| Model B (two-line) | Capacity up to 600 bags/min; film 12–35 µm; power 15–25 kW; larger footprint | Suited for high-volume production and multi-shift operations |

| Model C (biodegradable-ready) | Capacity up to 400 bags/min; film 20–40 µm; power 10–18 kW; adjustable sealing systems | Designed for PLA/PBAT blends and mixed product lines |

Understanding these specifications helps match production goals to machine capabilities, and the next subsections explain capacity and control-system impacts in detail.

Typical production capacity ranges reflect machine architecture: single-line machines commonly produce up to ~300 bags per minute under optimal conditions, while two-line high-speed configurations can reach up to ~600 bags per minute depending on film gauge and bag size. Bag width and length capabilities vary with jaw stroke and film unwind capacity; common vest bag widths range from small produce sizes to wide retail grocery formats, and longer bags reduce maximum achievable cycles per minute. Film gauge strongly influences capacity — thinner films allow higher nominal speeds but require tighter tension and control to avoid defects. These capacity considerations determine expected tonnage per shift and feed directly into ROI calculations.

Selecting the right configuration requires balancing desired bags/minute against material type and anticipated typical bag dimensions for your customer base.

PLC control systems with user-friendly HMI panels store production recipes, enable quick changeovers, and provide live diagnostics that reduce troubleshooting time and maintain uptime. Recipe storage preserves optimal servo settings, sealing temperatures, and cutting parameters for each bag type so operators can switch products with minimal manual fine-tuning. Built-in error logging and remote connectivity options allow technicians to analyze fault trends and provide timely support, decreasing mean time to repair. Intuitive interfaces lower training time for operators and reduce configuration errors that can lead to scrap, enabling consistent quality across shifts.

Effective PLC integration therefore improves overall equipment effectiveness by making process parameters repeatable and transparent, which supports continuous improvement programs.

South African buyers can source full production lines and standalone t-shirt bag machines from suppliers that offer integration with blown-film extrusion, flexo printing, and recycling equipment, supporting end-to-end manufacturing. When evaluating suppliers, consider local stock availability, lead times for samples and bulk orders, warranty terms, and the supplier’s ability to provide installation and after-sales support. An effective buying checklist helps prioritize supplier capabilities and ensures alignment with production targets. The list below suggests practical procurement criteria for South African manufacturers.

Procurement checklist for buyers:

Plastic Bag Machine South Africa (operating as Kingdom Machinery Co., Ltd. in South Africa) positions itself as a supplier offering one-stop solutions from film extrusion to printing and recycling, competitive pricing from large-scale manufacturing, 100% final inspection before shipment, a two-year warranty on timer switches, and timely after-sales service with local presence references in Gqeberha, Soweto, Cape Town, and Johannesburg. These supplier strengths address core procurement concerns and help minimize installation and ramp-up risk.

Plastic Bag Machine South Africa emphasizes simple operation, robust performance, and ease of maintenance, qualities that lower the barrier to achieving stable production. Their one-stop approach — supplying blown-film extrusion, bag-making, flexo printing, and recycling equipment — enables integrated lines that minimize compatibility issues and shorten project timelines. Competitive pricing from large-scale production, fast delivery options, and a 100% final inspection policy aim to reduce supply uncertainty and early-life defects, improving confidence during commissioning. These supplier capabilities are particularly relevant for South African manufacturers seeking local coordination and predictable after-sales service.

After-sales support practices include 100% final inspection prior to shipment, a specified two-year warranty on timer switches, and commitments to timely service response as stated in supplier materials, which together reduce early operational risk. Practical support items to confirm with any supplier are availability of spare parts, remote diagnostic capability, installation and operator training at commissioning, and warranty claim procedures; these elements minimize downtime and sustain throughput. Local service presence in major South African cities helps shorten parts lead times and enables faster on-site troubleshooting compared with solely offshore support models. Verifying these support commitments during procurement helps ensure predictable lifecycle costs and stronger operational resilience.

Confirming service scope and spare parts logistics before purchase enables realistic planning for maintenance intervals and repair budgets.

Estimating pricing and ROI requires comparing upfront machine cost, operating expenses (material, labor, energy), and expected production output to calculate payback period and cost-per-bag metrics. A simple ROI framework divides annual net benefit (reduced labor + increased throughput + lower scrap) by total investment to estimate payback years; sensitivity to material price and utilization rates makes scenario analysis essential. Financing options in South Africa typically include equipment finance, leasing, or supplier payment plans, each with different cash-flow implications. The table below offers a sample ROI snapshot to illustrate how buyers evaluate investments and prioritize models during procurement.

Intro to ROI table: the values below show how capital and operating factors interplay to determine expected returns.

| Item | Attribute (Upfront Cost, Ongoing Cost, Production Output) | Estimated Value / Example |

|---|---|---|

| Machine Purchase | Upfront capital requirement for mid-range model | Example: relative mid-range baseline (varies by supplier and options) |

| Operating Costs | Material, energy, labor per month | Example: material cost major driver; labor reduced by automation |

| Production Output | Bags per month (utilization dependent) | Example: 300–600 bags/min scaled to monthly tonnage |

This table illustrates that ROI sensitivity is primarily driven by achieved utilization and material costs; accurate production modeling is essential for reliable payback estimates.

Machine cost must be balanced against efficiency gains such as increased throughput, lower labor input, and reduced scrap; a mid-range high-speed model can shorten payback when running multiple shifts or securing large-volume contracts. A simple cost-per-bag calculation divides total monthly cost (amortized machine cost + operating costs) by units produced; as throughput and utilization rise, cost-per-bag falls steeply, improving margins. Assumptions such as running hours per shift, scrap percentage, and resin price sensitivity heavily influence the payback period, so realistic scenarios using trial runs or supplier-provided performance data produce more accurate projections. Evaluating worst-case and best-case scenarios helps mitigate financing risk and supports negotiation on price or support terms.

These comparative calculations emphasize the importance of matching machine capability to expected production profiles and sales contracts.

Common financing approaches include equipment finance (term loans secured against the machine), leasing arrangements that preserve working capital, and supplier-led payment plans or staged payments tied to milestones; each approach affects cash flow differently. Equipment finance may offer predictable monthly payments, while leasing can include maintenance in the contract but may carry higher long-term costs; supplier payment plans sometimes offer favorable terms tied to installation or acceptance. When evaluating options, consider interest rates, term length, local currency exposure, and import duties where applicable, and assess whether after-sales service or spare parts are included in the financing package. A short checklist — compare total cost over term, flexibility of early repayment, and inclusion of service — helps select the most appropriate financing route.

Careful financing selection combined with conservative production estimates reduces the likelihood of stretched payback periods and supports sustainable expansion.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.