Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

High-precision gravure printing machines are industrial rotogravure presses engineered to reproduce high-fidelity images and consistent solids across long production runs for flexible packaging and plastic film substrates. These machines use engraved cylinders to transfer controlled volumes of ink through an intaglio process, delivering superior tonal range and repeatable color stability that packaging manufacturers depend on for brand-critical printing. This article explains how gravure/rotogravure works, identifies core components and quality controls, and compares gravure to alternative technologies so technical buyers can make informed equipment decisions. You will also find detailed technical specifications, customization pathways, and practical maintenance and troubleshooting guidance tailored to South African production environments. Practical sections cover model-level attributes, comparison tables for procurement decisions, and local sourcing guidance that includes supplier capabilities and after-sales considerations. Read on to learn how gravure printing achieves photographic quality on BOPP, PET, PE and related substrates, when gravure is the sensible choice over flexo, and how to maintain uptime through best-practice workflows and sensor-enabled predictive maintenance.

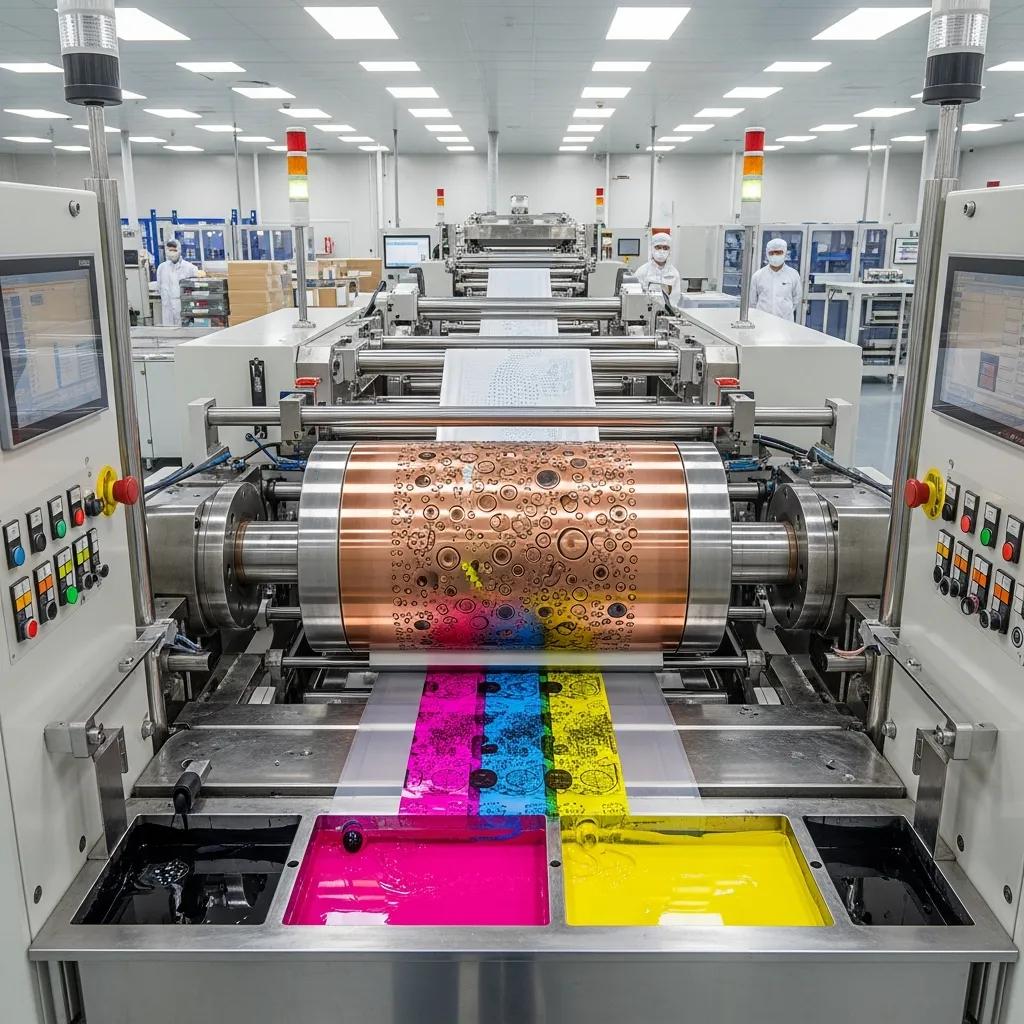

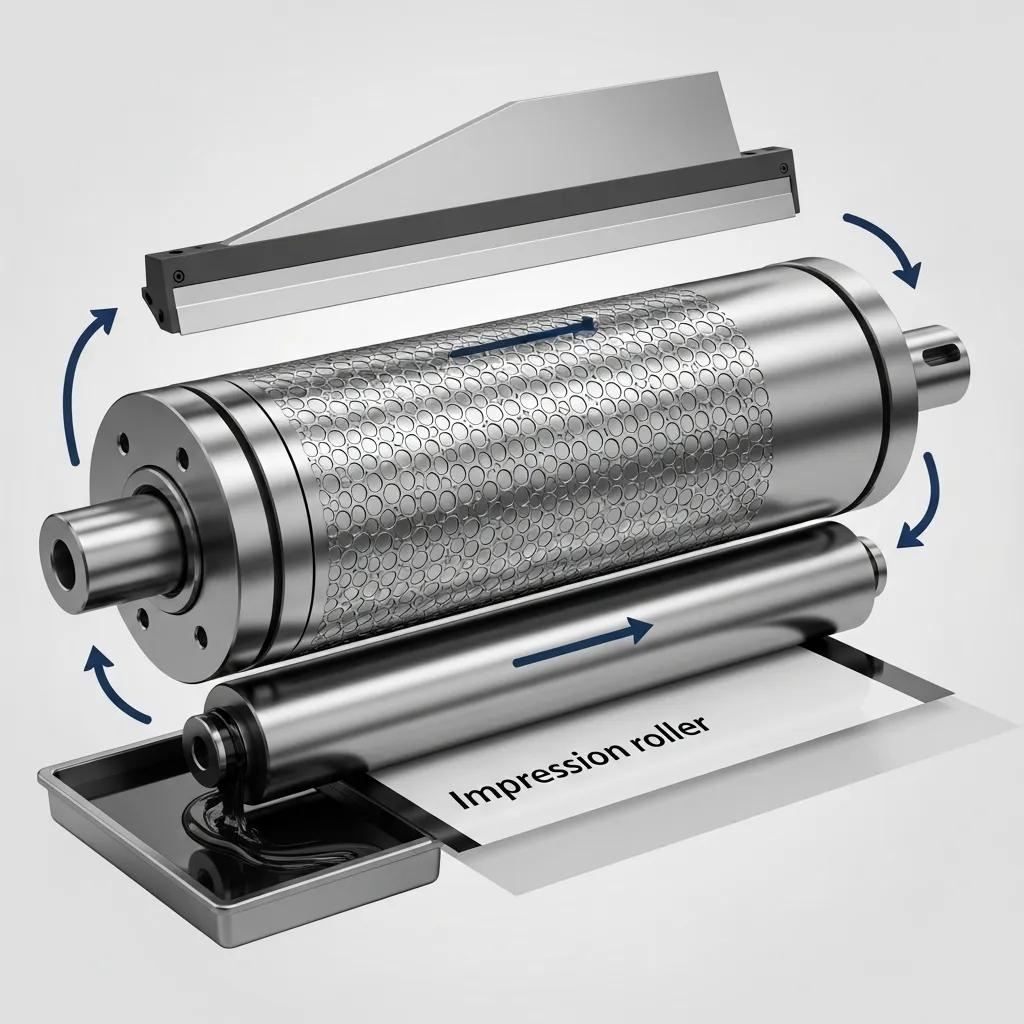

High-precision gravure printing machines operate by transferring ink from recessed cells engraved into a rotating cylinder onto a substrate using a controlled contact and drying sequence, which yields extremely consistent ink laydown and fine tonal graduation. The mechanism relies on precise engraving (cell depth and geometry), an ink fountain and doctor blade to meter excess ink, an impression roller to press substrate into the engraved cells, followed by staged drying units that fix the ink film; this sequence produces high-resolution images and uniform solids across long runs. Gravure excels on flexible packaging because the engraved cells provide controlled volume per unit area, minimizing dot gain and ensuring repeatability between repeats. Understanding component roles—cylinder engraving, metering, registration and drying—helps explain why gravure is preferred for long-run, high-quality packaging work. The next subsections detail rotogravure principles and list the machine components that make precision possible.

Rotogravure is an intaglio printing method where image cells engraved into a metal cylinder carry ink that is transferred to substrate, and its defining features include deep tonal range, continuous tone reproduction and stable repeatability. Engraving methods vary—mechanical diamond tool engraving and laser engraving are common—and cell geometry (shape, depth, and area) directly controls ink volume and tonal value, enabling photographic gradients and crisp solids. Typical industrial gravure presses operate at high web speeds while maintaining repeat accuracy due to robust cylinder construction and precise registration systems, making them cost-effective for long production runs. These attributes translate into lower unit costs on high volumes, consistent brand color fidelity, and superior print quality compared with many alternative technologies. Appreciating these features leads naturally into examining the machine components that implement the rotogravure process.

A gravure printing machine consists of a set of distinct subsystems that together control image transfer, ink management, web handling, and curing—each is critical to print quality and uptime. Core meronyms include the engraved printing cylinder (image carrier), doctor blade and ink pan (metering system), impression roller (transfer interface), drying units (thermal or IR drying), tension control system (web stability), and registration control (servo or electronic line shaft). Each part contributes specific functional attributes: cylinders determine image fidelity, doctor blades set wipe quality, drying systems fix ink quickly, and tension/registration systems preserve alignment at speed. Proper integration of these components enables the consistent, high-precision output demanded by flexible-packaging converters and prepares the ground for understanding machine selection criteria and customization options.

Key rotogravure components explained:

High-precision gravure presses deliver measurable advantages for packaging producers who require photographic imagery, stable color matching, and low unit costs on long runs, and industrial gravure machines are optimized to meet those needs through mechanical accuracy and robust process controls. The core value propositions include superior image fidelity from high-quality engraving, ease of operation and maintenance that reduce downtime, and consistent color repeatability enabled by precise metering and registration systems. For converters targeting flexible packaging markets—such as food packaging, laminates, and multi-color films—gravure provides long-run efficiency and predictable output quality that protect brand appearance and reduce waste. Below is a concise set of production benefits and buyer-focused attributes to help evaluators prioritize gravure when quality and volume align.

Production and operational benefits of high-precision gravure presses:

Gravure print quality stems from precise engraving, accurate doctor blade action, and advanced registration and tension control; together these systems regulate ink volume, dot shape, and substrate contact for consistent results. High-resolution engraving creates cells with exact volume and edge definition, while doctor blades and metering systems maintain a uniform ink layer on the cylinder surface to prevent streaking and banding. Closed-loop registration—via servo drives or electronic line shafts—and tension control preserve lateral and longitudinal alignment at high speeds, which reduces waste and rework. Process controls often include color measurement and inline spectrophotometers to monitor density and make automatic corrections, supporting tight tolerances necessary for brand-critical printing. With these systems in place, gravure presses produce repeatable, high-resolution output suited to flexible packaging production.

Gravure printing supports a broad range of flexible substrates commonly used in packaging, including BOPP, PET, PE (LDPE/LLDPE), PVC film, metallized foils, coated papers, and laminated structures; each substrate presents distinct ink adhesion and drying considerations. For non-polar substrates like polyethylene, surface treatment (corona or plasma) and appropriate solvent- or water-based inks improve ink wetting and adhesion, while PET and BOPP often require optimized drying profiles to prevent blocking or wrinkling. Metallized substrates and aluminum foils need careful ink formulation and thinner films to avoid thermal distortion during drying. Understanding substrate-specific pre-treatment and ink/drying matching reduces rejects and enables the press to maintain quality across mixed production runs. These compatibility considerations lead into detailed technical specifications and available customization options for gravure presses.

Technical specifications determine suitability for particular production profiles: speed (meters per minute), web width, number of color stations, drying system type, and registration accuracy are principal decision variables that buyers must consider. Typical high-speed gravure configurations vary by intended throughput and substrate: wide-web presses for large film rolls prioritize throughput, while specialty narrow-web presses emphasize quick job changeovers and precision. Customization options commonly include shaftless drive systems, in-line laminators, slitting and rewinding modules, upgraded drying systems (IR/air/UV), and advanced automation for registration and color control. The table below compares representative model families by those key attributes to help buyers align machine capabilities with production targets.

Introductory table explaining model comparison and selection guidance:

| Model Family | Typical Web Width | Max Speed (m/min) | Colour Stations | Drying Type |

|---|---|---|---|---|

| High-Speed Wide-Web | 1200–1800 mm | 200–400 | 6–12 | Multi-stage IR + hot air |

| Mid-Speed Flexible | 800–1200 mm | 100–250 | 4–8 | IR + convection |

| Specialty Narrow-Web | 400–800 mm | 80–180 | 2–6 | Compact IR or UV option |

This table helps manufacturers match model families to expected production volumes and substrate widths; next we summarize customization routes and logistics.

Customization often follows a standard R&D and configuration workflow where press width, number of color stations, and in-line modules are specified against production targets, and options such as automatic plate/cylinder changers, servo registration, and advanced drying are added to optimize performance. Plastic Bag Machine South Africa / Kingdom Machinery Co., Ltd. emphasizes R&D and customization capabilities—presenting ONE STOP SERVICE—to tailor presses for specific workflows, and they support ordering logistics including inspection and warranty protocols. When selecting custom features, prioritize web handling and drying upgrades where substrate heat sensitivity or high-speed runs are anticipated, as these choices directly affect throughput and yield. The following subsection lists model selection points and the types of customizations typically requested.

Model choices depend on production volume, repeat length and the substrate mix; high-speed families emphasize throughput and multiple color stations, while specialty models trade speed for flexibility and faster job changeover. High-speed wide-web machines are suited to large film reels and continuous packaging lines, offering many color stations and extensive drying capacity; mid-speed models balance speed with modular add-ons like in-line lamination or cold-seal applicators, and narrow-web presses excel at shorter runs with fine register control. Feature sets commonly include servo-driven registration, automated tension control, high-precision cylinder chucks, and modular in-line finishing units to reduce floor footprint while expanding capability. Choosing the right family involves matching expected run lengths, the number of colors needed, and whether in-line finishing will reduce downstream operations, which informs procurement and ROI calculations.

Customization pathways address capacity (web width and speed), process integration (in-line laminators, slitting, and rewinders), and automation (servo registration, remote diagnostics, recipe management) to fit specific production requirements. Examples include adding an in-line laminator and slitter for ready-to-ship substrates, upgrading drying capacity to handle high-solids inks on heat-sensitive films, or implementing shaftless drives for faster job changes and lower maintenance. Plastic Bag Machine South Africa / Kingdom Machinery Co., Ltd. reports strong R&D capabilities that support bespoke configurations through a ONE STOP SERVICE model, enabling converters to procure tailored presses with specified lead times and inspection protocols. When planning customization, define target throughput, substrate handling needs, and desired degree of automation to ensure R&D efforts focus on the highest-value adaptations.

| Customization Area | Typical Options | Production Benefit |

|---|---|---|

| Web Handling | Shaftless drives, tension control | Faster changeovers, reduced web breaks |

| Drying | IR, hot air, UV | Improved cure speed and substrate compatibility |

| In-line Finishing | Laminators, slitters | Reduced downstream operations, better throughput |

This table summarizes common customization areas, and the next section compares gravure with competing printing technologies to guide technology selection.

Gravure and flexo represent two leading industrial printing approaches for flexible packaging, and the optimal choice depends on run length, image complexity, substrate, and cost structure. Gravure delivers superior continuous-tone reproduction and unmatched consistency for very long runs, while flexo offers lower setup costs and faster job turnaround suitable for shorter runs and packaging where photographic reproduction is less critical. Key trade-offs include higher initial cylinder engraving cost and longer make-ready for gravure versus faster plate changes and lower tooling costs for flexo. To assist procurement decisions, the comparison table below contrasts fundamental attributes important to converters and brand owners.

| Attribute | Gravure | Flexo |

|---|---|---|

| Print Quality | Very high: photographic tones & smooth gradients | High: strong solids & good halftones with appropriate plates |

| Ideal Run Length | Very long runs (cost amortized over high volume) | Short to medium runs (quick job changes) |

| Setup Cost | Higher (engraved cylinders) | Lower (flexible plates) |

| Unit Cost for Long Runs | Low | Higher than gravure for very long runs |

| Substrate Compatibility | Excellent for many films, foils, laminates | Very good, especially with modern plate tech |

Gravure advantages include superior tone reproduction, excellent consistency across long runs, and predictable unit costs at scale; limitations are higher tooling costs, longer setup times, and a greater initial capital outlay for cylinders and engraving. Flexo advantages include lower initial setup cost, faster plate changes, and increasing image capability with modern plate technologies; its limitations are that it can struggle to match gravure’s continuous-tone fidelity for photographic images and may require extra screens or process work to approach similar tonal results. Production scenarios help guide decisions: very long, multi-color film runs with photographic art favor gravure, while frequent short runs with many SKU changes often favor flexo. Understanding these trade-offs enables converters to align technology with commercial targets and production cadence.

Quick list summarizing choice factors:

These choice factors naturally direct readers to the types of applications where gravure is most effective.

Gravure is especially well suited for high-volume food packaging, multi-layer laminates, decorative films, and products requiring photographic-quality branding and precise color matching across extended production runs. Applications that benefit most include snack food wrappers, laminated pouches with detailed imagery, metallized film packaging, and any flexible package where brand fidelity and color consistency justify the gravure tooling cost. Gravure also serves markets where long production runs enable tooling amortization and where downstream finishing benefits from high-quality, consistent printed substrates. These application insights lead directly into maintenance and troubleshooting considerations critical to preserving gravure’s performance advantage.

Effective maintenance for gravure presses focuses on preserving cylinder condition, doctor blade integrity, drying performance, and registration/tension systems to prevent common defects such as banding, streaks, or color shift. A structured maintenance schedule that includes daily cleaning, weekly inspections, and monthly preventive checks minimizes unexpected downtime and extends component life. Incorporating IoT sensors for vibration, temperature, and load monitoring enables predictive maintenance workflows that identify wear patterns before they become failures and reduce unplanned stoppages. The table below provides a quick troubleshooting EAV reference for common component-level faults and recommended corrective actions.

| Component | Common Issue | Recommended Action |

|---|---|---|

| Printing cylinder | Banding or inconsistent tone | Check engraving balance, clean and inspect cylinder, verify cell volume uniformity |

| Doctor blade | Streaking or smearing | Inspect blade wear, replace/resharpen, adjust blade angle and pressure |

| Drying system | Incomplete cure or blocking | Adjust temperature profile, check airflow, verify lamp output or heater performance |

| Tension control | Wrinkling or register drift | Calibrate tension sensors, verify web path alignment, inspect rollers for wear |

This troubleshooting table gives operators a concise reference to resolve common faults quickly; next we provide maintenance best practices and IoT deployment guidance.

Routine cylinder care includes regular cleaning with appropriate solvents, inspection for corrosion or wear, accurate storage to prevent deformation, and controlled handling during installation to preserve cell geometry; these practices maintain engraving fidelity and print consistency. Doctor blade maintenance requires daily inspection for nicks or uneven wear, correct blade tensioning to avoid chatter, and scheduled replacement intervals based on run length and substrate abrasiveness. Implementing standardized changeover checklists—covering cylinder flanges, chucks, blade seating, and impression roller settings—reduces setup variability and improves first-run quality. Proper handling techniques and consumables management extend component life, which reduces long-term operating costs and preserves the press’s ability to deliver high-precision output.

Maintenance checklist overview:

These maintenance rhythms tie into how modern sensors can further reduce downtime through predictive alerts.

IoT sensors complement routine maintenance by continuously monitoring parameters such as vibration signatures, bearing temperatures, motor load, and tension stability to detect anomalies that precede failures, enabling condition-based servicing rather than calendar-based interventions. Data from vibration and temperature sensors can identify bearing wear or motor overload early, while load cell and tension sensors detect drifting web tension that causes register issues; analytics platforms flag trends and trigger maintenance actions before quality is impacted. Pilot deployments often show measurable reductions in unplanned downtime and maintenance cost, and small-scale sensor retrofits are recommended to validate ROI before full-scale rollout. Integrating sensor data into operator dashboards and maintenance workflows institutionalizes predictive maintenance and enhances overall press reliability.

South African manufacturers sourcing gravure equipment should evaluate suppliers on technical capability, customization and R&D support, quality assurances, lead times, and local service presence to ensure long-term operational success. Key procurement questions include: What inspection and warranty processes are in place? What are sample and bulk delivery lead times? Is there local technical support, spare parts availability, and training for operators and maintenance teams? Comparing supplier claims against demonstrable inspection reports, references, and logistics timelines helps reduce purchase risk and supports business continuity planning. The following subsections describe how Plastic Bag Machine South Africa / Kingdom Machinery Co., Ltd. serves local manufacturers and how prospective buyers can request case-specific information.

Plastic Bag Machine South Africa is a South African-focused platform for Kingdom Machinery Co., Ltd., a Chinese manufacturer established in 2005. The company specializes in a comprehensive range of plastic bag production machinery including high-precision gravure printing machines, blown film extrusion, flexo printing machines, and plastic recycling machinery. Machines are described as having simple operation, perfect performance, easy maintenance, and timely after-sales service. Quality assurances listed include 100 percent final inspection and a two-year warranty on timer switches. Company claims competitive pricing and fast delivery (samples within 3 days, bulk within 15-20 days for standard machines). They offer strong R&D and customization (‘ONE STOP SERVICE’) and report over 1700 machines installed worldwide. The SERP mentions a specific focus on serving the South African market in cities such as Johannesburg, Cape Town, Gqeberha, and Soweto.

While specific client-identifying case studies are typically shared on request, an effective case-study format for gravure procurement follows a Problem → Solution → Results template that highlights throughput improvements, yield gains, and quality metrics after installation. For example, a hypothetical case summary would present the production challenge (e.g., inconsistent color and high scrap), the selected machine and custom features (e.g., upgraded drying and servo registration), and quantifiable outcomes (reduced scrap rates, improved line speed, and higher first-pass yield). Prospective buyers are encouraged to request supplier-provided case studies and production data to verify performance claims and to arrange sample trials. Asking suppliers for repeatability reports, on-site commissioning plans, and training offerings helps ensure the selected machine meets local production and quality requirements.

Items to request from suppliers when evaluating case histories:

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.