Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Eco-friendly biodegradable blown film machines are specialized blown film extrusion systems designed to process biodegradable polymers into flexible films for packaging, compostable bags and agricultural uses. These machines combine tailored screw and barrel geometries, precise temperature control, and optimized air ring cooling to form films from PLA, PBAT and starch-based biopolymers while preserving material properties and compostability. Readers will learn how these systems differ from conventional PE/PP lines, which biodegradable resins they handle, and what production and sustainability advantages they enable for converters and brand owners. The article maps the blown film extrusion process, quantifies benefits such as reduced post-consumer waste and regulatory alignment, compares machine configurations including monolayer and multi-layer co-extrusion, and outlines real-world applications from compostable retail bags to biodegradable mulch films. Throughout, we integrate practical vendor considerations for South African manufacturers and show how one-stop suppliers can simplify the transition to sustainable plastic film production.

Eco-friendly biodegradable blown film machines are blown film extrusion equipment purpose-built or configured to process biodegradable polymers into continuous tubular film, providing compostable and degradable alternatives to conventional plastic films. These systems differ from standard blown film lines by incorporating features that manage polymer sensitivity—such as gentle screw designs, precise heating zones, and enhanced melt filtration—to preserve mechanical and compostability properties. They are used to produce films for compostable bags, food-contact packaging and agricultural films where end-of-life biodegradation or industrial compostability is required. Understanding the material set and process adaptations is essential before selecting a production line, because polymer chemistry, moisture sensitivity and required barrier performance drive both machine selection and downstream converting choices.

Kingdom Machinery Co., Ltd. (Operating as Plastic Bag Machine South Africa) supplies relevant equipment categories that match these needs, including blown film extrusion machinery and bio bag machines, offering one-stop solutions that can be configured for PLA, PBAT and starch-based processing. Their production capabilities and service offerings position them as an example of a supplier able to support converters transitioning to biodegradable film production. This practical vendor context helps converters evaluate machine readiness while remaining focused on process fundamentals that determine film quality.

Biodegradable blown film lines commonly process three material families: polylactic acid (PLA), PBAT blends and starch-based biopolymers. PLA derives from fermented plant sugars and yields clear, stiff films with good sealability; it requires narrow processing temperatures and effective moisture control to avoid hydrolytic degradation. PBAT is a flexible, aliphatic-aromatic co-polyester used to impart toughness and elongation in blends and is more tolerant of melt processing but benefits from precise temperature profiling to maintain molecular integrity. Starch-based films use thermoplastic starch or starch-filled blends to reduce fossil content and cost; they typically need compatibilizers and careful handling to maintain mechanical properties. Selecting the right polymer or blend depends on target film attributes—clarity, tensile strength, sealability and compostability—so machine features must align with material-specific processing windows and pre-drying requirements.

Understanding these polymer distinctions leads naturally to the next topic: how the blown film extrusion process must be adapted for biodegradable polymers to protect their functional and end-of-life properties.

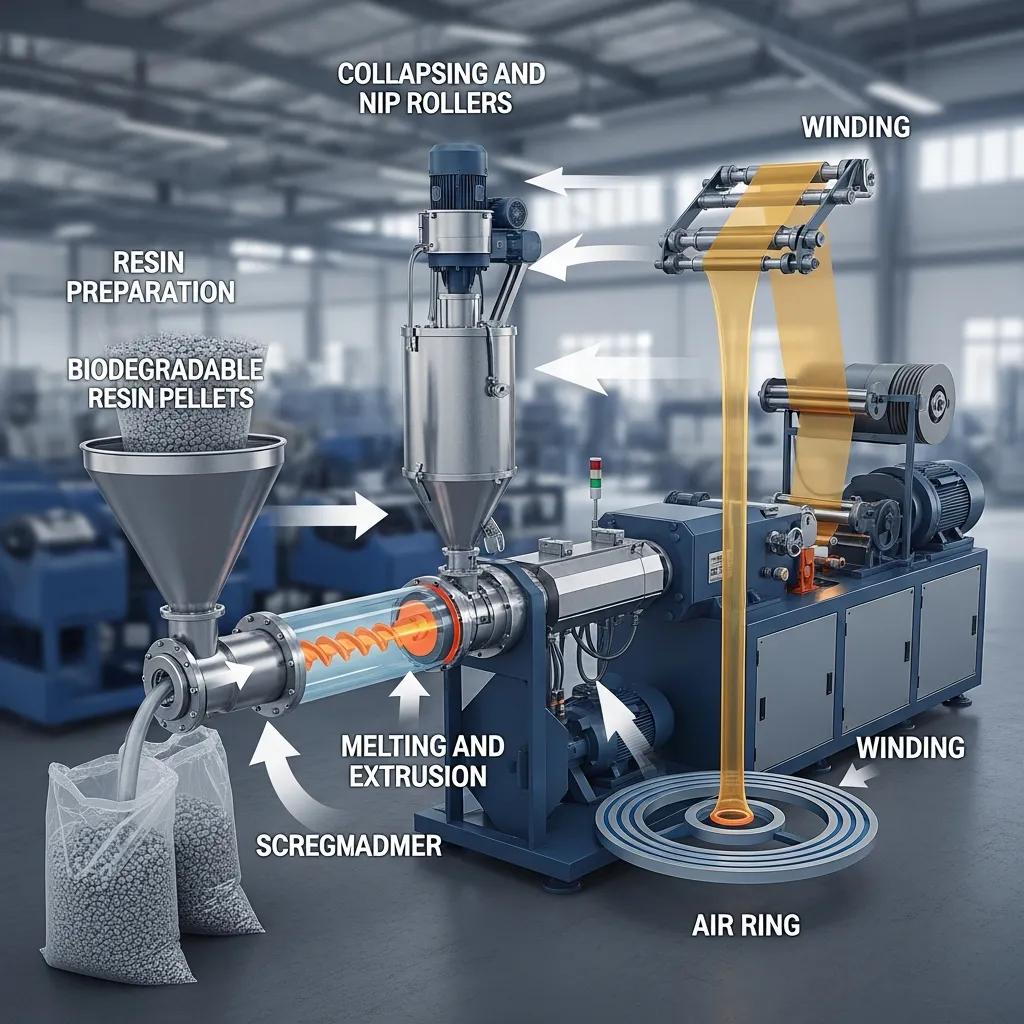

The blown film extrusion process for biodegradable films follows the same core steps as conventional film blowing but places tighter control on melt quality, moisture management and cooling. First, resin is metered and thoroughly dried to reduce hydrolytic degradation risk; then a screw extruder melts and pressurizes the polymer for extrusion through a circular die. An air ring forms a controlled bubble that determines bubble stability and film orientation, while precise haul-off and winding systems set film thickness and layflat consistency. Critical controls for biopolymers include segmented barrel temperature zones, gentle screw geometry to limit shear, and in-line filtration or degassing to remove volatiles—measures that preserve mechanical performance and compostability. Proper process control ensures the film meets application requirements and regulatory compostability standards, so converters must match machine capability to the polymer’s sensitivities.

To show the core steps clearly for operators and technical buyers, the process can be summarized in an actionable step list.

These steps demonstrate how machine mechanics translate into film attributes and lead into a discussion of why investing in the right equipment yields measurable benefits.

Biodegradable blown film machines deliver environmental, regulatory and market-facing advantages by enabling the production of compostable and biodegradable films that reduce reliance on fossil-based polymers and align with evolving packaging mandates. They help brands meet compostability standards and consumer demand for sustainable packaging while creating new product lines such as certified compostable bags and mulch films. Operationally, modern biodegradable-capable lines offer energy-efficient drives and process controls that can reduce per-ton energy consumption compared with older equipment, and they integrate with downstream converting and printing systems for a streamlined workflow. For manufacturers evaluating ROI, benefits include access to premium market segments, reduced end-of-life waste for customers, and the ability to produce differentiated, certified products that support sustainability claims.

The practical business outcomes of these benefits can be summarized in a compact EAV-style table that maps benefit to metric and business impact.

The following table compares key business and environmental benefits of adopting biodegradable film extrusion capability:

| Benefit | Metric | Business outcome |

|---|---|---|

| Regulatory alignment | Compostability standards compliance (e.g., EN 13432) | Enables market access where compostable packaging is required |

| Waste reduction | Reduced persistent plastic in end-of-life streams | Strengthens sustainability claims and CSR reporting |

| Market differentiation | Ability to supply compostable/biodegradable films | Access to premium customers and new channels |

| Operational efficiency | Energy-efficient drives and optimized controls | Lower per-ton production cost and improved margins |

This EAV comparison clarifies how technical upgrades translate into measurable business value and prepares manufacturers to weigh capital and operating trade-offs.

Biodegradable blown film lines enable production of films that can meet recognized compostability and biodegradability standards, which is essential for regulatory compliance and procurement requirements. By using certified biodegradable polymers and controlling processing to maintain compostable properties, manufacturers can supply films and bags that decompose under industrial composting conditions, reducing the persistence of plastic waste in landfills and the environment. Additionally, switching to biodegradable materials for disposable applications like shopping bags or mulch film lowers the long-term environmental burden and supports circularity initiatives when combined with appropriate collection and composting infrastructure. Machine-level features—such as low-shear screws, moisture-controlled drying, and melt filtration—ensure that end products retain the polymer chemistry required to meet labelling and verification protocols.

Investing in biodegradable blown film machinery brings both near-term and long-term financial implications: initial capital for upgraded extrusion and downstream converting is offset by margin expansion in premium sustainable product lines, potential energy savings from modern drives, and reduced material costs when blending biopolymers with fillers. Typical ROI considerations include raw material pricing volatility, product yield and waste reduction during processing, and conversion profitability for compostable bags or specialty films. Maintenance and warranty terms also affect total cost of ownership; reliable spare parts availability and responsive service reduce downtime and improve lifetime ROI. Manufacturers should model scenarios for small and medium production scales to assess payback timelines and include sensitivity to material blends and end-customer pricing.

The following table provides a concise mapping of key cost and ROI attributes:

| Cost Factor | Description | Business implication |

|---|---|---|

| Capital expenditure | Upgrades for low-shear extruders and co-extrusion heads | Requires planning but enables premium product lines |

| Energy consumption | Modern drives reduce kWh per ton | Lowers operating expenses over machine life |

| Material strategy | PLA/PBAT blends and fillers affect cost | Balances performance and raw material expense |

| Service & warranty | Availability of parts and online support | Improves uptime and predictable maintenance costs |

These metrics help frame realistic financial expectations and support investment decisions in sustainable film production.

Kingdom Machinery Co., Ltd. (Operating as Plastic Bag Machine South Africa) markets blown film extrusion machinery and complementary equipment suitable for biodegradable film production, including bio bag machines and systems that integrate flexo printing and recycling solutions. Their portfolio emphasizes ease of operation, competitive pricing and fast delivery, with standard machines available within short lead times and post-sale 24-hour online support. For converters in South Africa seeking configurable lines for PLA, PBAT or starch-based films, suppliers that provide one-stop solutions—extrusion, printing, converting and recycling—simplify setup and optimize the production chain. When evaluating suppliers, prioritize proven process features like degassing, segmented heating zones and integrated drying systems that Kingdom Machinery highlights across its offerings.

Below is an EAV-style comparison to help technical buyers compare equipment types and material compatibility without relying on specific model numbers.

| Machine type | Compatible materials | Typical production notes |

|---|---|---|

| Monolayer blown film machine | PLA, PBAT, starch blends | Simpler setup, suitable for single-layer compostable bags |

| Multi-layer co-extrusion machine | PLA/PBAT combinations; barrier layers | Enables barrier/performance tuning with co-extruded layers |

| Bio bag converting line | Compostable films, printing and cutting | Integrated converting for bag making and finishing |

This table helps buyers match material needs to machine class and introduces the vendor context for follow-up discussions. Kingdom Machinery’s one-stop approach also extends to downstream equipment such as flexo printers and recycling machines to close the production loop.

Optimizing PLA and PBAT extrusion requires machine features that control shear, temperature and moisture while ensuring uniform melt quality. Recommended elements include screw and barrel designs with gentle compression ratios to minimize polymer chain scission, segmented heating zones for precise thermal profiling, and in-line dryers or dehumidification to reduce moisture-induced hydrolysis. Melt filtration and optional degassing ports remove volatiles that can cause defects, while accurate air ring control and chill profiling set film orientation and mechanical properties. Quality control features—such as thickness gauges, film optical inspection and automated tension control—help maintain consistent film attributes and reduce waste during production.

A short features list highlights core technical priorities for buyers:

These priorities flow into co-extrusion considerations, where multi-layer strategies address barrier and mechanical gaps.

Multi-layer co-extrusion machines enable combining biodegradable layers with specific functions—sealant, barrier and structural—to achieve performance parity with conventional films while retaining compostability in certified formulations. A typical multi-layer structure might place a moisture-resistant sealant layer next to a structural core and a thin barrier blend to improve oxygen or aroma barrier; materials and layer thicknesses are chosen to balance compostability, mechanical integrity and seal strength. Co-extrusion solves single-polymer performance limitations by allowing each layer to perform a dedicated role, and modern feedblocks and co-extrusion heads provide tight layer control for consistent film performance. Processing multi-material stacks requires careful attention to melt viscosity matching, thermal zones and layer encapsulation to avoid delamination and to preserve end-of-life properties.

Understanding multi-layer design leads to consideration of target applications where layered performance is essential, which we explore in the next section.

Films produced by biodegradable blown film machines serve a broad spectrum of commercial applications including compostable retail bags, food-contact packaging, agricultural mulch films and specialty retail and industrial films. Each application imposes different requirements for clarity, sealability, tensile strength and degradation profile, so manufacturers must tailor resin selection and film structure to end-use, whether that is high-clarity compostable film for produce packaging or thicker, more durable mulch films that degrade in-field. Converters often combine blown film production with flexo printing and bag-making to deliver finished products, creating cross-sell opportunities for integrated suppliers. Practical selection criteria include barrier needs, shelf-life targets, converting compatibility and end-of-life compostability certification.

The following table maps applications to typical film specs and example end-products to help manufacturers choose production targets:

| Application | Typical film specs | Example end-products |

|---|---|---|

| Compostable retail bags | 15–40 µm; good seal strength; high clarity | Shopping bags, produce bags |

| Food packaging | 15–100 µm; barrier-modified layers; printable surface | Fresh produce trays, bakery bags |

| Agricultural mulch film | 30–80 µm; controlled degradation; tensile strength | Mulch film rolls for crop rows |

This mapping helps converters choose formulations and machine settings appropriate for their target markets and sets the stage for a practical converter workflow.

Manufacturing compostable bags begins with resin selection—choosing PLA, PBAT or starch-based formulations that match required mechanical and compostability attributes—and continues through controlled extrusion and converting operations. The workflow includes drying and melting, blown film extrusion with correct orientation and thickness control, inline flexo printing compatibility for branding, and finishing steps such as bag cutting, sealing and perforation. Quality control checkpoints include seal integrity testing, compostability verification against standards, and optical inspection for clarity and print quality. Converters should maintain traceability of resin batches and document processing parameters to support claims and certification, ensuring that finished products perform in both use and end-of-life scenarios.

A concise converting checklist helps ensure quality and compliance:

These operational checks prepare producers for the distinct requirements of agricultural films discussed next.

Biodegradable mulch films reduce plastic persistence in agricultural fields by degrading after the cropping season, eliminating the need for retrieval and disposal associated with conventional polyethylene mulch. These films are formulated for controlled degradation rates, mechanical strength during the crop cycle and compatibility with soil biology; they often incorporate PBAT blends or starch-filled formulations tailored to agronomic needs. Processing mulch films requires wider film thickness ranges and attention to toughness, elongation and UV behavior, and producers must balance degradation speed with crop protection performance. Field trials and lifecycle assessments demonstrate agronomic benefits such as reduced labor for film removal and lower long-term plastic contamination, although successful adoption depends on matching formulations to local climate and soil conditions.

Understanding these application-specific trade-offs feeds into regional support needs for manufacturers in key markets like South Africa.

Kingdom Machinery Co., Ltd. (Operating as Plastic Bag Machine South Africa) supports sustainable plastic film manufacturing in South Africa by offering blown film extrusion equipment, bio bag machines and complementary solutions such as flexo printing and recycling machines tailored to local converter needs. Their value proposition emphasizes ease of operation, strong R&D, one-stop/custom solutions, competitive pricing and fast delivery for standard machines, contributing to reduced time-to-production for converters. The company also highlights quality inspection practices, a two-year warranty for timer switches, energy-efficiency features and 24-hour online service, which together help local manufacturers maintain uptime and meet production targets. For South African customers in cities such as Johannesburg, Cape Town and Gqeberha, working with a supplier that bundles extrusion, printing and converting can streamline supply chains and reduce integration complexity.

Local market dynamics in South Africa—driven by municipal waste management policies, procurement preferences for compostable packaging and buyer demand in urban centers—shape machine configuration and material choices for converters. Regulatory drivers may include requirements for compostability claims and growing retailer sustainability standards that favor certified biodegradable films, prompting manufacturers to focus on traceability and testing. Labor skill levels and operational scales influence machine complexity and automation: smaller converters often prefer user-friendly, easy-to-operate lines while larger producers invest in co-extrusion and automation for higher throughput. Machine suppliers must therefore offer configurable solutions that balance automation, operator training needs and cost-effectiveness to meet local conditions.

Understanding local needs leads to evaluation of after-sales support offerings, which directly affect machine uptime and ROI.

Effective after-sales support for blown film lines includes installation, operator training, spare parts availability, remote troubleshooting and warranty coverage, all of which reduce downtime and protect production schedules. Kingdom Machinery emphasizes 24-hour online service, quality inspection prior to shipping, and warranty coverage for specific components such as timer switches, which supports predictable maintenance outcomes. Training ensures local teams can operate and maintain sensitive drying and extrusion controls necessary for biodegradable polymers, while accessible spare parts and responsive support minimize lead times for repairs. These services together improve uptime and enable converters to meet delivery commitments and quality expectations for compostable film products.

For converters ready to explore equipment options and local support, suppliers with one-stop capabilities simplify procurement and integration. Kingdom Machinery Co., Ltd. (Operating as Plastic Bag Machine South Africa) can provide matched extrusion, printing and converting solutions for South African manufacturers seeking to scale sustainable film production.

The market for biodegradable film extrusion is expanding as demand for compostable packaging and sustainable agricultural films grows, driven by regulatory pressure, retailer procurement policies and consumer preference for lower-impact packaging. Current research indicates increasing interest in PBAT-based blends for flexibility and PLA for clarity, while material science advances are improving blend performance and cost-efficiency. Equipment-level innovations focus on energy-efficient drives, better automation for process stability, and improved co-extrusion heads for multi-layer biodegradable constructions. These trends suggest growing capital investment in machines that can handle a broader range of biopolymers and produce higher-performance, certified films over the next decade.

Understanding market growth and innovation helps manufacturers plan capacity and product roadmaps, which is explored in the following subsections.How Is the Global Biodegradable Films Market Growing and Evolving?

The global biodegradable films market is experiencing robust growth as brands and regulators accelerate the shift away from conventional plastics, with rising application penetration in packaging and agriculture. Key growth drivers include stricter packaging regulations, increasing retailer sustainability commitments, and consumer willingness to pay premiums for compostable packaging. Regions with strong regulatory frameworks and composting infrastructure see higher demand for certified films, while emerging markets present adoption challenges tied to collection and end-of-life systems. For South African manufacturers, these global signals imply growing local opportunity provided they can meet certification requirements and optimize production for cost-competitive compostable products.

This market momentum encourages technological innovation in materials and equipment, discussed next.

Innovations shaping sustainable film extrusion include improved biopolymer blends that enhance mechanical and barrier properties, energy-efficient servo drives and smarter process automation that reduce rejects, and advanced co-extrusion technology enabling thinner, multi-functional layers. Material innovation such as PBAT/PLA compatibilizers and bio-based barrier additives help close performance gaps with fossil-based films, while equipment advances in melt control and online quality measurement improve yields. Buyers should request features supporting moisture control, degassing and precise layer control from vendors and evaluate energy and automation options that lower total cost of ownership. These innovations collectively make biodegradable blown film production more competitive and scalable for manufacturers seeking sustainable product lines.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.