Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Plastic bag making machines convert polymer resin into finished bags used across retail, packaging, and industrial markets. This guide explains the machine classes relevant to Kempton Park manufacturers, how recycling equipment supports circular production in Gauteng, the automation features that raise throughput, and practical buying and maintenance considerations to optimise ROI. Buyers in Kempton Park and surrounding Gauteng areas need clear technical criteria—capacity, film type, print options, and integration with recycling—to choose the right line for their product mix and sustainability goals. The article maps machine types (extrusion, printing, bag making, recycling), compares cooling strategies and automation features, outlines pricing drivers, and provides maintenance best practices to keep uptime high. Throughout, you’ll find comparison tables, actionable checklists, and guidance on evaluating suppliers including how Plastic Bag Machine South Africa’s capabilities align with local buyer needs.

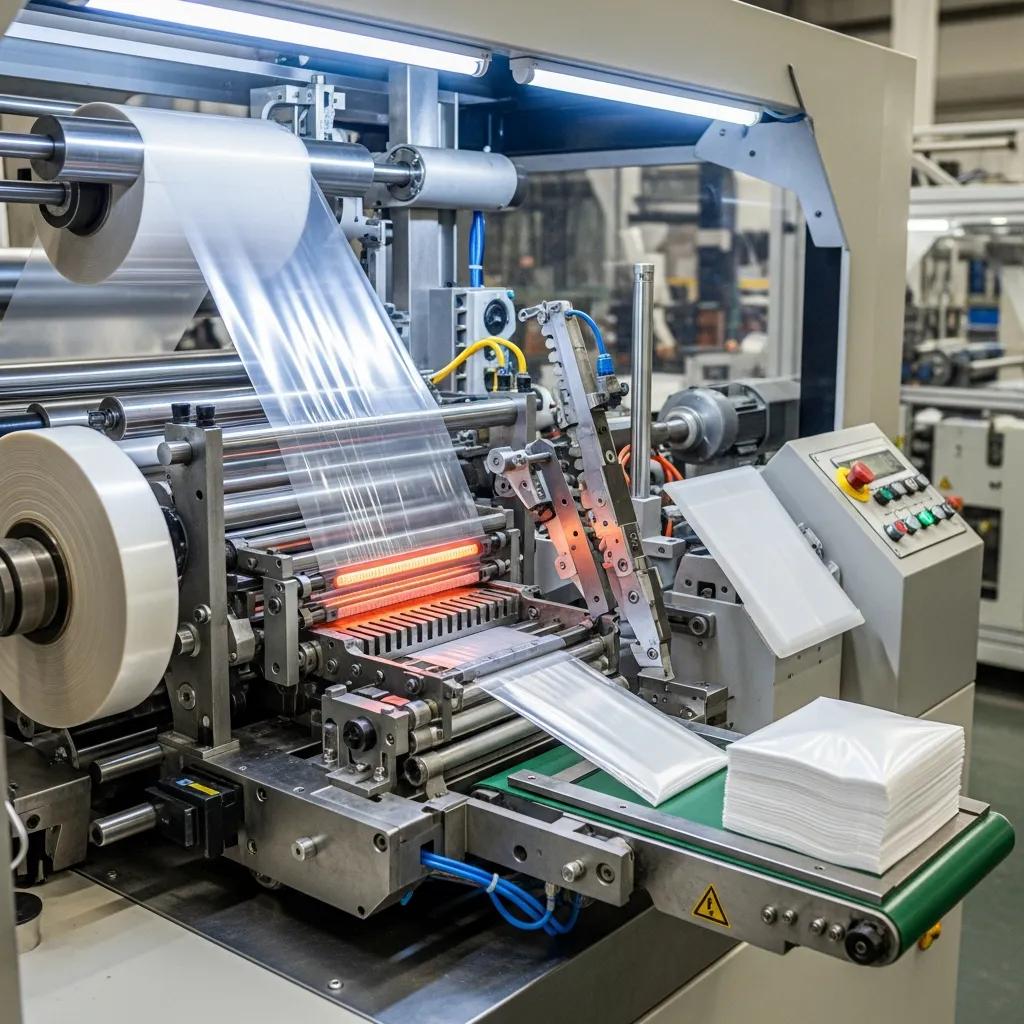

Plastic bag production lines typically include blown film extrusion to make film, flexo printing for brand graphics, and conversion machines to cut, seal, and stack bags. Each class performs a defined role: extrusion creates the film substrate, printing applies graphics, and bag-making machines convert film into finished SKUs. Choosing the right combination depends on raw material (HDPE/LDPE/LLDPE), desired bag type, throughput targets, and whether integrated recycling or printing is required. Below is a compact comparison to help identify which machine class matches specific production goals and common Kempton Park use-cases.

| Machine Class | Core Attribute | Typical Value / Application |

|---|---|---|

| Blown film extruder | Production capacity | 50–600 kg/hr; produces HDPE/LDPE/LLDPE film for bags |

| Flexo printing unit | Print color & width | 1–6 colors; up to 1600 mm web width for branding |

| Bag making machine | Sealing & cutting | T-shirt, side-seal, bottom-seal modes; up to 200 pcs/min |

| Recycling pelletizer | Reprocessing output | 30–300 kg/hr of regrind/pellets for reuse |

This table highlights how extrusion capacity maps to conversion speed and how print options influence final product value. The next subsection explains blown film extrusion in more technical detail, beginning with how melt flow and die design control film quality.

Blown film extrusion melts polymer resin and forces it through an annular die, inflating the extruded tube into a bubble that determines film thickness and orientation. The process controls film properties—tensile strength, clarity, and barrier performance—through screw design, cooling ring, and haul-off speed, making it central to producing HDPE, LDPE, and LLDPE films. Monolayer machines are simpler and cost-effective for single-resin films, while multilayer extruders combine materials (e.g., virgin and recycled content) to balance strength and cost. Understanding layer configuration and output (kg/hr), along with film width and thickness (microns), guides selection toward either mono or multilayer lines suited to grocery bags, shrink wrap, or heavy-duty sacks.

Blown film choices lead naturally into printing requirements because film quality affects ink adhesion and registration; the next subsection explains flexo printing integration and its trade-offs.

Flexo printing units apply water- or solvent-based inks onto the film web using rotating plates, enabling 1- to 6-color branding with high-speed registration. Print unit features to evaluate include color stations, drying systems, and registration tolerance—critical when producing retail bags with precise artwork and barcodes. Choosing between 2-color and 6-color units balances cost and marketing needs: two colors handle logos and simple designs affordably, while six colors allow full-process graphics that increase perceived value but slow effective line speed. Printing also affects downstream processes: more colors and heavier inks can require drying capacity and tighter tension control to avoid registration drift.

When considering combined extrusion and printing lines, manufacturers should weigh print quality against throughput impacts and determine if inline printing meets their volume and branding ambitions.

For buyers who want supplier recommendations or integrated solutions, Plastic Bag Machine South Africa offers a range of blown film extruders and flexo printing options and can provide quotations and equipment configurations tailored to Kempton Park production goals. Requesting a quote helps clarify lead times and module selections for your intended bag types.

Plastic recycling machines process production scrap and post-consumer material into reusable pellets or flake, enabling manufacturers to recover material costs and reduce landfill waste. Recycling equipment—granulators, washing lines, and pelletizers—stabilizes feedstock quality so recycled content can re-enter blown film extruders with predictable melt flow and mechanical properties. Integrating recycling supports regulatory compliance, lowers raw material spend when virgin resin prices rise, and strengthens sustainability claims that matter to brand-conscious retailers. Below is a short list of core sustainability benefits to highlight the practical value of recycling integration.

These operational benefits lead directly to choices about recycling technology—particularly the cooling method—which the next subsection compares to help determine the right fit for a Gauteng production environment.

Water-cooled recycling lines use wash tanks and water-ring pelletizers to rapidly cool melt, producing dense, uniform pellets while requiring water management and treatment systems. Air-cooled systems rely on forced-air conveyors or strand cooling and are advantageous where water resources are limited or where simplified wastewater handling is a priority. Water cooling typically yields slightly better pellet quality for high-throughput lines, while air cooling simplifies installation and reduces water treatment CAPEX. Maintenance and footprint trade-offs matter: water systems need filtration and sludge management, whereas air systems require robust dust control and longer cooling distances.

Choose water cooling for high-volume reprocessing with onsite water treatment; choose air cooling when water use must be minimised or when floor layout constraints make water tanks impractical. The following subsection summarizes benefits of integrating recycling equipment into existing lines.

Integrating recycling equipment close to extrusion and conversion lines captures scrap before contamination and enables immediate reuse, improving material yield and lowering per-bag resin cost. Practical benefits include stabilized resin blends when pelletized regrind is mixed with virgin resin at controlled ratios, reduced logistics for waste handling, and the ability to offer products with declared recycled content. Integration also supports traceability when combined with batch control and helps manufacturers respond quickly to material shortages. For many Kempton Park operations, the capital cost of a compact recycling line is recouped within months through material savings and avoided disposal fees.

Producers considering integration should evaluate: footprint and layout, target recycled content percentage, and whether supplier support includes commissioning and operator training. If you want a turnkey recycling-capable solution, Plastic Bag Machine South Africa lists recycling machines and configurable options and can prepare a tailored proposal on request.

Automatic plastic bag making machines unite film feed, cutting, sealing, perforation, and stacking into a continuous, programmable line that reduces labour and increases repeatability. Core automation elements—PLC controls, servo drives, and auto-stacking modules—create precise length control, fast changeovers, and consistent weld quality, raising throughput while lowering scrap. These features translate into predictable OEE improvements and reduced operator count; examples include consistent seal integrity for high-barrier bags and rapid SKU changeover for seasonal demands. The following table compares automation features with direct operational benefits to help quantify potential gains.

| Automation Feature | Attribute | Operational Benefit |

|---|---|---|

| PLC control | Centralised logic & recipe storage | Faster changeovers and repeatable production |

| Servo drives | Precision motion control | Accurate bag length and reduced material waste |

| Auto-stacking | Automated collection & packing | Lower labour and faster dispatch readiness |

| Touchscreen HMI | Operator interface | Easier troubleshooting and reduced downtime |

Understanding these automation components clarifies expected performance improvements and guides investment decisions, which leads into concrete efficiency examples in the next subsection.

Automation raises effective throughput by increasing uptime, reducing human error, and enabling higher line speeds while maintaining quality standards. Typical performance improvements include 15–40% higher output compared with semi-automatic lines, 20–50% reduction in labour hours per shift, and significantly lower reject rates due to consistent sealing and length control. Implementation requires operator training, initial tuning and commissioning, and spare-parts planning, but the resulting predictability simplifies scheduling and cost forecasting. These efficiency gains enable smaller manufacturers in Kempton Park to compete on delivery lead times and product consistency, particularly for customers demanding regular supply.

Quantifying expected ROI depends on current labour costs, scrap rates, and desired capacity; the next subsection outlines which bag types are supported by automated lines and the specific modules that enable them.

Automatic conversion machines can produce a wide spectrum of bag formats—t-shirt (vest) bags, side-seal carrier bags, bottom-seal grocery bags, gusseted sacks, and specialist formats—by switching sealing bars, dies, and feed configurations. Each bag type requires distinct film width, perforation options, and sometimes additional equipment such as punching or handle attachments, so machine modularity is important for flexible production schedules. T-shirt bags are common in retail, side-seal bags suit lightweight packaging, and bottom-seal bags provide strength for heavier contents; selecting the right modules ensures quick SKU changes and reliable output. Buyers should assess cycle speed for each bag type and confirm whether the supplier provides changeover kits or modular upgrades.

Choosing equipment that supports the required bag formats directly impacts machine ROI and the ability to expand SKUs without purchasing new capital equipment.

Selecting a reliable supplier requires evaluating warranty terms, after-sales support, spare-parts availability, and proven delivery lead times for Kempton Park logistics. Buyers should prioritise suppliers offering clear commissioning, operator training, and documented parts lists so maintenance and uptime expectations are realistic. Local availability of technicians or remote support and spare-parts stock reduces downtime risk and improves long-term TCO. Use a checklist when vetting suppliers to compare service levels, warranty commitments, and production capacity alignment with your planned volumes.

Plastic Bag Machine South Africa positions itself to meet local buyer needs by emphasising quality assurance, R&D, one-stop services, and production capacity. The company highlights 100 percent final inspection with defective product rates controlled between 1 and 3 percent, a two-year warranty on timer switches, and dedicated R&D teams for product, structural, software, and circuit engineering. Their production footprint includes multiple production lines and an internal laboratory with testing equipment, enabling customised solutions from prototype to mass production. For buyers seeking competitive pricing, configured quotes can clarify options and lead times.

When evaluating offers, ask for references, machine acceptance criteria, and sample output to verify performance under your operating conditions. The next subsection outlines how these supplier capabilities translate into local success stories.

Plastic Bag Machine South Africa offers a one-stop service model that covers customised product development, logos, labels, packaging solutions, and end-to-end production transition support. Their stated unique value propositions include strict quality assurance with low defective rates, strong R&D capabilities across product and software domains, significant production capacity with many assembly lines, competitive pricing through large-scale production, and fast delivery timelines for samples and standard machines. These features address common procurement pain points for Kempton Park manufacturers—particularly when buyers need tailored equipment and reliable lead times. Requesting a quotation from the company helps align technical specifications with local production and sustainability targets.

Manufacturers that integrate appropriate extrusion, printing, and recycling modules report measurable improvements such as reduced scrap rates, lower material spend, and faster order fulfillment cycles. For example, integrating a recycling pelletizer with a blown film extruder can reduce virgin resin purchase by a predictable percentage, and automating conversion can decrease manual packing labour while increasing throughput. Localised case improvements typically centre on material yield, defect reduction, and faster SKU changeovers achieved through combined supplier support and operator training. When considering a supplier, request anonymized performance metrics or production samples to corroborate claimed benefits and to replicate similar outcomes in your plant.

Concrete metrics and verified runs help buyers forecast payback periods and decide between different equipment configurations.

Machine cost varies widely based on class, capacity, level of automation, and included options such as inline printing or recycling integration; budget ranges typically reflect these variables rather than a single market price. High-level cost bands depend on whether you need a compact mono-extruder with a simple bag maker, a full multilayer film line with flexo printing, or an integrated line including recycling and automation. Buyers should treat published ranges as preliminary and request bespoke quotes because configuration choices have the largest impact on final price. The table below summarises the main factors that influence cost to guide initial budgeting.

| Cost Driver | What It Affects | Typical Impact on Price |

|---|---|---|

| Machine type (mono vs multilayer) | Extruder complexity | Significant — multilayer raises cost |

| Automation level | PLC, servo, auto-stacker | Moderate to high — improves throughput |

| Printing options | Number of colors, drying system | Adds cost per color station |

| Recycling integration | Wash, pelletizer or granulator | Adds CAPEX but reduces OPEX over time |

Understanding these drivers allows buyers to prioritise which features deliver the greatest value for their production goals, which leads into the next subsection on specific factors in more detail.

Several attributes change price materially: the number of extruder screws and barrels (which increase throughput), multilayer capability (coextrusion heads and layer distributors), number of printing stations, and the presence of servo drives and advanced HMI controls. Additional add-ons such as automatic bag stacking, cutting dies, and inline recycling modules each have incremental costs but can reduce total cost of ownership through labour savings or material reuse. Lead times and custom engineering also increase cost if unique tooling or special materials are required. Buyers should build an itemised specification and request quotes based on the exact configuration to avoid surprises.

These price factors influence the decision to buy new or used equipment, which the next subsection addresses.

New machines come with factory warranties, predictable lead times for spare parts, and the latest automation and safety features; they typically cost more upfront but lower risk and maintenance unpredictability. Used machines offer lower initial capital outlay but carry higher risk of hidden wear, limited or expired warranty support, and potential scarcity of replacement parts for older models. Consider total cost of ownership: factor in warranty scope, expected uptime, retrofit needs for modern controls, and service support availability. For many buyers, lightly used, well-documented machines with available spare parts and the option for supplier commissioning provide a middle ground between cost and risk.

Careful inspection and, ideally, trial runs or sample production on used equipment reduce purchase risk and ensure you meet production quality standards.

Consistent maintenance and quick troubleshooting protocols preserve throughput and reduce unplanned downtime across extrusion, printing, and conversion equipment. A structured maintenance program covers daily checks, weekly lubrication and alignment, monthly inspections, and a stocked spare-parts plan for critical wear items. Quick diagnostics for common faults—film thickness variation, sealing faults, or print registration drift—allow operators to resolve many issues without waiting for specialist service. The list below summarises routine checks operators should perform before each shift to catch issues early.

Daily tasks should include verifying extrusion melt temperature profiles, checking cooling ring performance, confirming print registration stability, and inspecting sealing jaws for residue or wear. Weekly tasks expand to include alignment checks, lubrication of gearbox and bearings, tightening of electrical connections, and inspection of vacuum and pneumatic lines. Monthly tasks should cover full mechanical inspections, verification of safety guards, and a parts inventory check for critical spares like heaters, cutters, and seals. Maintaining a documented log of maintenance actions and production anomalies supports trends analysis that can pre-empt failures and inform spare-parts ordering.

A disciplined maintenance cadence reduces emergency service calls and supports consistent product quality, which is why many suppliers include commissioning and training in their service packages.Common Issues and How to Resolve Them Efficiently

Many recurring production problems are solvable with methodical diagnostics: inconsistent film thickness often stems from screw wear or die lip damage, sealing faults may result from misaligned jaws or incorrect temperature settings, and printing registration drift usually traces to web tension or plate wear. A simple troubleshooting matrix helps operators isolate causes: check mechanical alignment, verify set-points in the PLC, inspect consumable components, and escalate when repairs require machine downtime or component replacement. When escalation is necessary, documented fault logs and production samples help supplier technicians replicate and resolve issues faster.

Use a structured Issue → Likely cause → Quick fix → When to escalate workflow to empower operators to solve routine faults while retaining clear escalation triggers for specialist service.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.