Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

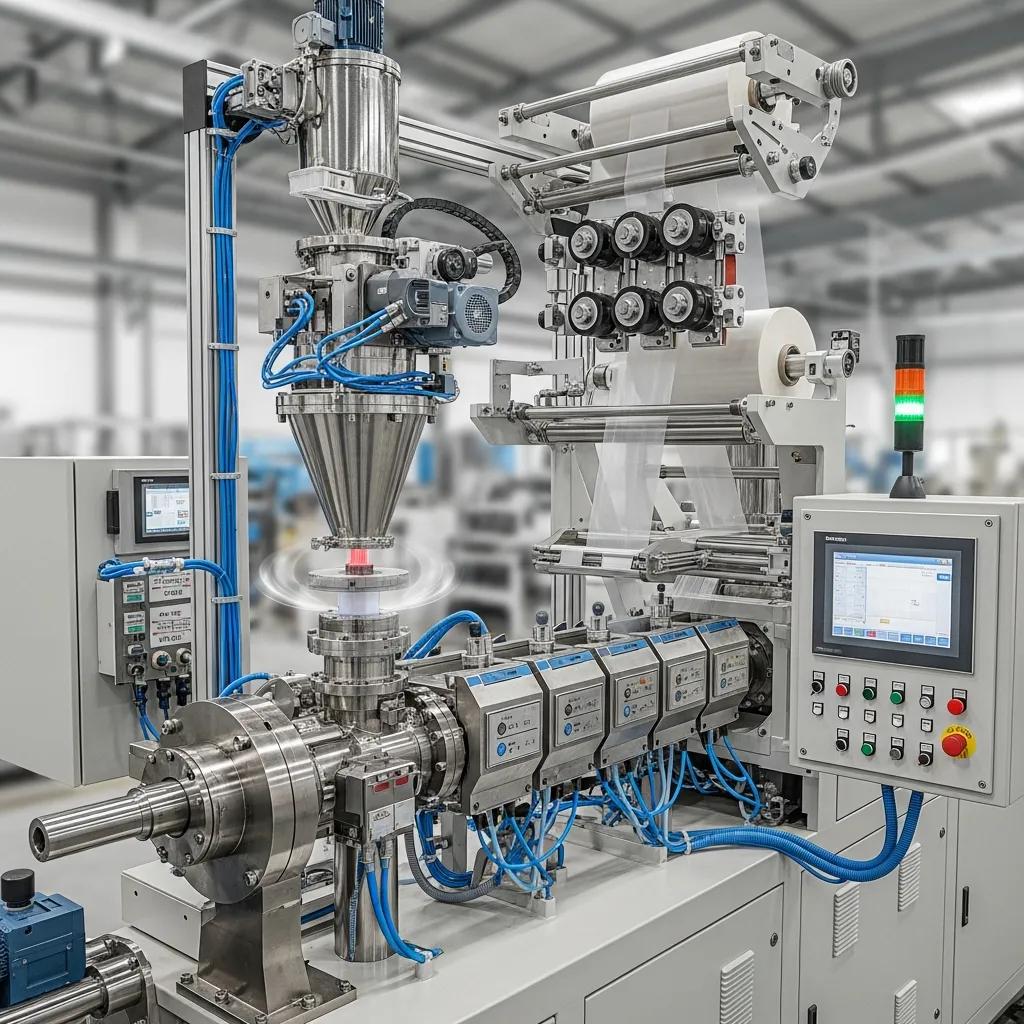

Blown film extrusion is the industrial process of converting thermoplastic resins into tubular film by extruding a molten polymer through a circular die and expanding it with controlled air, producing flexible packaging films and bags. This guide explains how blown film extrusion machines work, why Germiston-based manufacturers and packagers choose local production, and how to match machine types and features to production goals. Many businesses in Gauteng seek reliable, energy-efficient lines that handle HDPE, LDPE, and LLDPE with tight gauge control and low scrap rates; this article addresses those operational needs and offers practical buying guidance. Read on for a step-by-step look at commercial advantages, machine categories, key technologies, local supplier support, pricing drivers, and sustainable recycling integrations tailored to Germiston plastic film production.

Blown film extrusion machines let manufacturers control film properties—gauge, width, and material composition—close to their point of use, reducing per-unit cost and shortening lead times compared with outsourcing. Producing film on-site translates to faster iterations of film recipes, fewer logistics constraints, and immediate access to spare parts and service, which improves uptime and responsiveness for Germiston operations. Local production also enables tighter quality control and customization for carrier bags, agricultural film, and flexible packaging, which helps brands respond to market demands and regulatory changes. The next section outlines concrete examples of these commercial benefits to help buyers quantify savings and performance improvements.

Local plastic film production reduces dependency on overseas suppliers by cutting transit times and import risk, which lowers inventory carrying costs and shortens time-to-market for new SKUs. Manufacturers gain direct control over film gauge and additives, enabling consistent product performance and fewer rejects; this results in measurable material savings and improved first-pass yield. Immediate access to nearby service and spare parts increases line availability, while on-site customization supports product differentiation and small-batch runs. Understanding these operational advantages leads naturally into how specific extruder features deliver efficiency and cost-effectiveness.

These benefits demonstrate why many Germiston manufacturers prioritize investing in blown film capability, and they set the stage for examining the mechanical and automation features that enable those gains.

Blown film extruders improve efficiency through optimized melt management, inverter-driven motors, and automated control loops that balance throughput with film quality, reducing scrap and energy consumption. Precise temperature control and servo/inverter systems allow tighter process windows, which translate to lower start-up waste and higher run-to-run consistency for gauges and tensile properties. Automation reduces labour requirements for line adjustments and enables repeatable recipes for multilayer co-extrusion, improving cost-per-meter for produced film. With that operational background, the next section compares the main machine types available to Germiston buyers and explains which applications each serves best.

Blown film extrusion lines range from simple monolayer systems for basic bag production to complex multi-layer co-extrusion lines that combine different polymers for barrier, strength, or recycled-content layers; capacity and automation level determine suitability for different business scales. Small bench or lab extruders support R&D and short runs, while industrial lines deliver high throughput for continuous film production; material compatibility and screw diameter influence which resins each line processes efficiently. Below is a compact comparison to help buyers choose between monolayer, two- to seven-layer co-extrusion, and recycled-compatible configurations.

Different blown film line types fit specific production needs and materials.

| Line Type / Model Category | Layers | Typical Output (kg/hr) | Materials |

|---|---|---|---|

| Monolayer small-scale | 1 | 30–80 | HDPE, LDPE, LLDPE |

| Mid-tier industrial monolayer | 1 | 100–300 | LDPE, LLDPE, HDPE |

| Multi-layer co-extrusion line | 3–7 | 150–800 | LDPE, LLDPE, HDPE, PP, recycled blends |

Monolayer blown film lines are mechanically simpler and cost-effective for basic carrier bags, shrink film, and straightforward flexible packaging, providing acceptable mechanical properties with low capital investment. Multi-layer co-extrusion lines combine layers with distinct functions—such as a recycled regrind core with virgin surface layers—to deliver improved barrier, puncture resistance, and tailored mechanical performance while enabling sustainable content. Choosing between them depends on product requirements: monolayer lines favor simplicity and low running cost, while multilayer lines favor performance and recyclability strategies. When comparing options, buyers should consider whether they need barrier properties, printed surfaces, or recycled core layers, as that decision directly affects die design, downstream printing, and winding equipment.

HDPE, LDPE, and LLDPE each demand different processing windows: HDPE requires higher stiffness and controlled cooling, LDPE needs tight melt and gauge control to achieve low-thickness flexible film, and LLDPE benefits from optimized shear and die designs for toughness. Typical machine configurations indicate screw diameters and barrel heating zones that match resin melt characteristics; for example, smaller-diameter screws with specialized air rings help control cooling for thin LDPE film, while larger screws support higher throughput or reclaimed-content blends. Customers should specify desired film thickness, width, and end-use (carrier bags, agricultural film, shrink-wrap) when requesting machine recommendations, so the extrusion line can be matched to material and product targets.

Modern blown film extrusion lines incorporate several advanced features—automatic temperature control, rotary die heads, inverter speed control, and in-line quality sensors—that materially improve film uniformity, energy efficiency, and throughput. These technologies work together to reduce gauge variation, minimize start-up scrap, and enable precise layer distribution in co-extrusion lines; they also support integration with downstream flexo printing and winding systems. The table below maps common features to their operational benefits so buyers can prioritize specifications during procurement.

Key extrusion features and their impact on production performance.

| Feature | Benefit / Impact | Measurable Outcome |

|---|---|---|

| Automatic temperature control | Better melt homogeneity | Lower gauge variation, fewer rejects |

| Rotary die head | Improved film uniformity | Smoother winding and less edge trim |

| Inverter speed control | Match extrusion to haul-off | Stable film thickness and energy savings |

| In-line thickness sensor | Real-time feedback control | Immediate corrective adjustments |

Automatic temperature control maintains consistent barrel and die temperatures to ensure uniform polymer melt viscosity, which directly reduces gauge variation and surface defects across production runs. By stabilizing melt conditions, automatic control shortens start-up time and reduces the volume of off-spec film, improving first-pass yield and lowering raw material waste. Tight temperature regulation also enables repeatable recipes for different polymers and facilitates co-extrusion where interlayer adhesion depends on matched melt conditions. Understanding temperature control’s role leads naturally into how mechanical components like rotary die heads complement thermal management to improve film uniformity.

Rotary die heads distribute melt circumferentially and reduce die lip temperature gradients, which improves film concentricity and thickness uniformity; this mechanical optimization results in higher-quality winding and reduced edge trim. Inverter speed controls synchronize screw RPM, haul-off, and winder speeds to maintain stable draw-down ratios and precise film gauge, enabling quick adjustments for recipe changes and variable outputs. Together, rotary die heads and inverter drives enable smoother transitions between runs and support energy-efficient operation by matching motor loads to process demands. These mechanical and control synergisms are essential when integrating printed film operations or recycling feedstock into extrusion lines.

Plastic Bag Machine South Africa operates under Kingdom Machinery Co., Ltd. and supplies a portfolio of film production and downstream equipment including blown film extrusion machines, plastic bag making machines, flexo printing machines, and plastic recycling machines. The company emphasizes simple operation, reliable performance, easy maintenance, and timely after-sales service, providing local customers with equipment options and customization to match production requirements. For Germiston businesses seeking reduced lead time and lower procurement risk, the supplier offers consultation, line design input, and coordination for installation and commissioning in the Gauteng region. The following table clarifies the core services available and what customers can expect in scope and response.

| Service | Scope | Typical Value |

|---|---|---|

| Installation & commissioning | On-site setup and trial runs | Ensures correct line start-up |

| Operator training | Hands-on machine operation training | Faster ramp-up and safer operation |

| After-sales support & spare parts | Spare parts supply and technical support | Shorter downtime and predictable maintenance |

After-sales services include on-site training during commissioning so operators learn safe procedures and process recipes, scheduled maintenance packages to maintain uptime, and spare parts supply to minimize repair lead times. Remote diagnostics and technical guidance are also part of the support mix, allowing technicians to troubleshoot process variations quickly and reduce extended stoppages. The supplier’s emphasis on timely after-sales service helps Germiston customers maintain continuous operation and manage total cost of ownership. These support elements flow into how customers can request consultation or a formal quotation for a tailored line.

To request a consultation or quote, prepare basic production parameters: desired film width, target thickness range, primary resin(s), required output (kg/hr or m/min), and any downstream integration needs such as flexo printing or bag making. Providing samples or typical product specifications accelerates the consultation and helps suppliers suggest appropriate screw diameters, die sizes, and automation packages. Expect a structured quotation process that clarifies machine configuration, customization options, and lead time estimates; this preparation ensures suppliers can provide an accurate proposal for Germiston operations. With machine selection clarified, buyers can evaluate cost drivers which are discussed next.

These steps reduce ambiguity in procurement and improve the accuracy of vendor proposals.

Buyers frequently ask what materials can be processed, how much machines cost, and what site preparations are required; understanding these factors helps align expectations for performance, budget, and timeline. Material compatibility, automation level, and customization needs drive price, while electrical supply, floor loading, and ventilation influence site readiness and installation complexity. The next subsections answer the two most common technical and commercial questions concisely to support buyer decision-making in Germiston and greater Gauteng.

Blown film extruders commonly process HDPE, LDPE, LLDPE and, with appropriate screw and die design, polypropylene blends and recycled pellets; line configuration determines effective throughput and film properties. Recycled plastics can be incorporated as regrind or pellet feedstock when upstream recycling and pelletizing equipment ensure consistent particle size and low contamination levels. Process adjustments—such as modified temperatures, screw geometry, and increased degassing or filtration—help manage variability introduced by recycled content. Managing contamination and quality control is essential to maintain film appearance and mechanical properties when using recycled resins.

Machine cost is driven by capacity/output, number of layers (monolayer vs. co-extrusion), level of automation (sensors, in-line control), and customization for recycled-content processing or downstream integration; these factors define capital and operating expenditure. Rather than fixed prices, buyers should view tiers—entry-level monolayer lines for basic bags, mid-tier automated lines for consistent production, and high-end multilayer lines with inline sensors and higher throughput. Total cost of ownership considerations—energy consumption, spare parts, training, and maintenance agreements—often exceed purchase price in long-term planning. Understanding these cost drivers enables Germiston buyers to balance initial capital with expected production savings.

These cost insights prepare buyers to evaluate proposals and prioritize specifications that align with their commercial objectives.

Sustainable film production pairs recycling machines with extrusion lines to convert film waste into regrind or pellets, enabling closed-loop or partially recycled-content products that meet corporate sustainability goals and regulatory trends. Integrating washing, pelletizing, and extrusion requires quality control steps—contamination screening, moisture removal, and compatibilizers—to preserve film performance when using recycled feedstock. The environmental and commercial benefits of recycled-content film include lower raw material cost, improved sustainability claims for customers, and potential regulatory alignment; the following subsections explain equipment pairings and benefits in practical terms.

Recycling machines prepare used film by washing, drying, and pelletizing waste into a consistent feedstock suitable for film extrusion; this workflow is waste → cleaning → pelletizing → extrusion, with QC checks at each stage. Proper integration reduces contamination risk and stabilizes melt flow, enabling co-extrusion recipes that blend recycled and virgin layers for performance retention. Quality control measures such as sink-float separation and optical sorting improve pellet quality and reduce rejects in the extrusion process. Effective recycling integration therefore directly supports higher recycled content in finished film without sacrificing product quality.

| Equipment | Role | Benefit |

|---|---|---|

| Washing & separation | Removes contaminants and separates polymers | Cleaner feedstock reduces defects |

| Pelletizer | Converts regrind into uniform pellets | Consistent melt behavior in extruder |

| Drying & moisture control | Lowers moisture before extrusion | Prevents hydrolytic degradation |

Using recycled plastics lowers material costs and strengthens sustainability credentials by reducing virgin resin demand and landfill input, which benefits corporate social responsibility and regulatory compliance. Recycled content can also enable new market positioning for eco-conscious brands, though it may require formulation tweaks—such as compatibilizers or targeted layer placement—to mitigate changes in mechanical properties. Manufacturers should weigh trade-offs: some processing complexity and additional QC are necessary, but the net result can be reduced raw material spend and improved environmental impact metrics. Adopting recycled feedstock leads into operational planning considerations like supplier qualification and line configuration to maintain consistent product performance.

These benefits show why integrating recycling into film production is both commercially and environmentally advantageous for Germiston manufacturers.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.