Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Plastic bag making machines convert polymer film into finished bags rapidly and with consistent quality, and choosing the right equipment is the single biggest factor that determines manufacturing efficiency and product profitability. This guide explains machine categories, the role of blown film extrusion and flexo printing, recycling and water-cooling solutions, cost drivers and realistic price bands, and how to set up a production line in Durban and KwaZulu-Natal. Many Durban manufacturers and entrepreneurs struggle with matching capacity to market demand, ensuring film quality for printing, and integrating recycled content while complying with local requirements; the right machine selection resolves those issues and improves ROI. Below we map the types of machines available locally, step through blown film extrusion and printing options, cover recycling equipment and pricing, and finish with practical setup and after-sales expectations for suppliers and service in South Africa. Throughout, keywords such as plastic bag machine Durban, blown film extrusion machine South Africa, and plastic recycling machine Durban are used to help buyers and planners find relevant options and make informed procurement decisions.

Plastic bag making machines available to Durban businesses span automatic and semi-automatic bag makers designed for T-shirt bags, side-seal bags, garbage bags, shopping bags and air-bubble/air cushion film production. These machines differ by automation level, material compatibility (HDPE, LDPE, LLDPE, biodegradable films), production speed and typical end-use. Knowing the basic categories helps buyers match equipment to volume targets and labor availability, which reduces waste and increases throughput. Below is a short enumerated list of common machine categories and one-line descriptions to aid quick selection and featured-snippet style clarity.

The main machine types include:

These categories highlight typical applications and immediately point to which machine families to evaluate next when selecting capacity and optional features for Durban production.

Different machine classes have distinct capacity, speed and material profiles, so the table below compares the most common types to help buyers decide which class aligns with their production goals.

| Machine Category | Typical Output (bags/hr) | Film Types Compatible | Automation Level | Typical Use Case |

|---|---|---|---|---|

| T-shirt Bag Machine | 1,500–6,000 | HDPE, LDPE, LLDPE | High (automatic cutting/sealing) | Retail carrier bags |

| Side-Sealing Machine | 1,000–4,000 | LDPE, LLDPE, biodegradable | Medium–High | Packaging, produce bags |

| Garbage Bag Machine | 800–3,000 | HDPE, thicker films | Medium–High | Refuse bags, industrial use |

| Air Bubble Film Machine | Variable (m²/h) | LDPE, LLDPE | Medium | Protective cushioning film |

This comparison clarifies which machine categories tend to fit specific market segments: high-speed automatic T-shirt machines for retail carriers, side-seal for flexible packaging, and garbage bag machines for thicker film applications. The next step is assessing automatic models and the detailed features that affect daily operation and maintenance.

Automatic bag making machines best suited to South African operations combine production capacity, energy efficiency and accessible service support to minimize downtime and maximize yield. Buyers should prioritize machines whose output matches forecasted order volumes while leaving headroom for growth, and prefer PLC-controlled systems for repeatable settings and easier troubleshooting. Reliability and local spare-parts availability are critical because prolonged downtime directly reduces revenue; insist on visible test records and clear maintenance schedules when evaluating vendors. Consider production footprint and labor; automatic machines reduce operator requirements but require trained technicians for preventive maintenance and adjustments, so plan staffing and training accordingly.

Assess service expectations and procurement checklists before purchase; ask about warranty scope, on-site commissioning, spare-part lead times and remote support options. These procurement criteria lead naturally into feature-level comparisons—cutters, sealing systems and in-line automation—which determine long-term operational costs and bag quality across different film materials.

Feature sets for common bag machine categories focus on cutter type, sealing method, speed ranges and optional upgrades such as PLC control, automatic splicing and in-line printing. T-shirt bag machines emphasize fast cutting and reinforced handle perforation, while side-sealing machines prioritize precise heat sealing and consistent gusset formation. Garbage bag machines require stronger sealing systems and higher-torque drives to handle thicker films. Optional upgrades like automatic film splicing, PLC recipe storage, and servo-driven motors improve efficiency and reduce scrap, but they also raise upfront cost.

Maintenance features matter: easy-access cutter assemblies, replaceable sealing bars and modular electrical cabinets reduce downtime and simplify repairs. Selecting compatible film ranges (HDPE vs LLDPE) determines bag strength and finish; therefore, match film grade to product requirements and choose machines with adjustable sealing temperature and dwell time for consistent output. Understanding these core features helps buyers compare machine proposals on technical merit rather than brand alone.

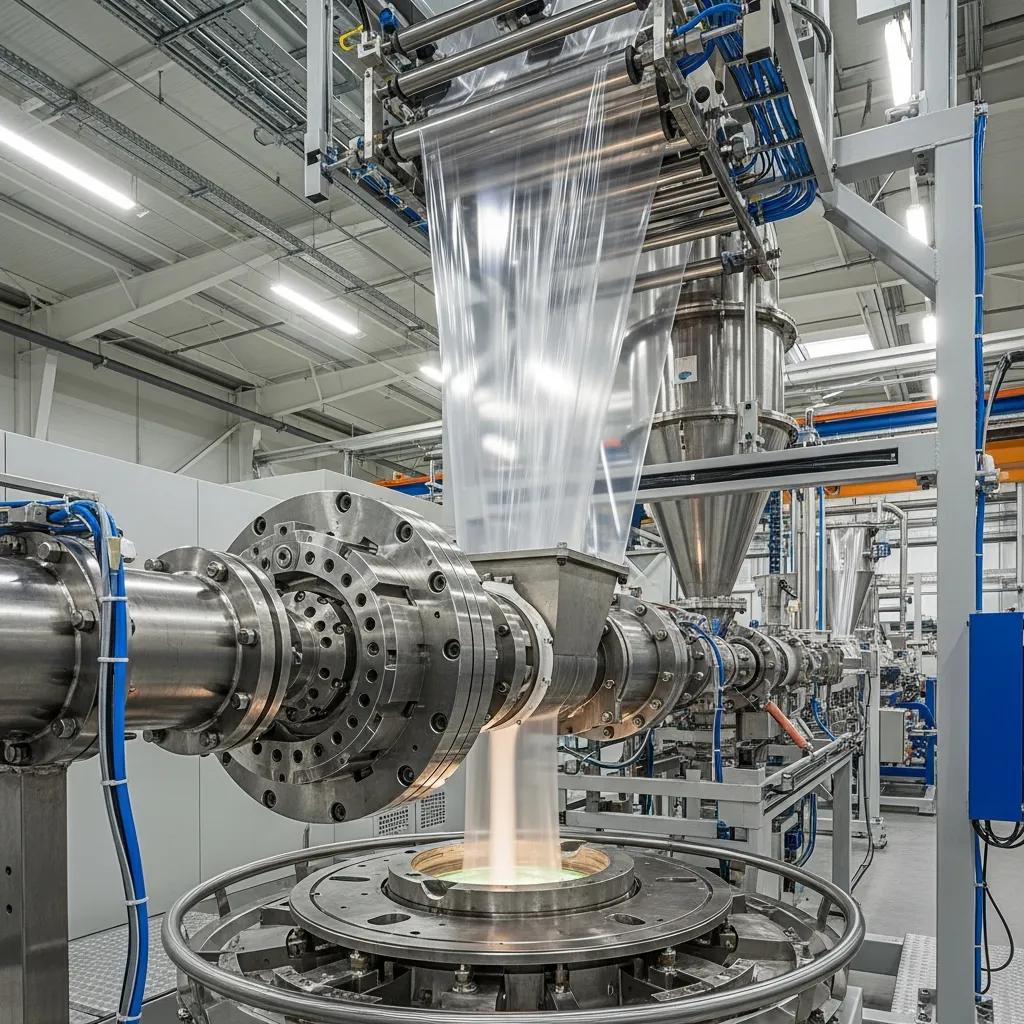

Blown film extrusion creates continuous plastic film by extruding molten polymer through a circular die and inflating it into a bubble, which delivers uniform film thickness, multilayer options and efficient material usage for downstream bag-making. The process improves film strength-to-weight ratios and enables co-extruded layers that combine barrier, stiffness and sealability properties, making it especially valuable for manufacturers who require custom film performance. Multilayer blown film systems support barrier layers or recycled content blends, while monolayer systems offer simplicity and lower capital cost, so the choice depends on product specification and recycling goals. For Durban manufacturers, blown film capability upstream of bag making simplifies supply chains, reduces film procurement costs and gives tighter control over film gauge and printability.

Below is a compact comparison of blown film extruder specifications to help buyers choose machines by screw diameter, film width and output capacity.

| Extruder Type | Screw Diameter (mm) | Film Width (mm) | Output (kg/h) | Typical Use |

|---|---|---|---|---|

| Monolayer Small | 45–65 | 600–1000 | 40–120 | Small retail bags |

| Co-extrusion 3-Layer | 75–120 | 1000–1600 | 200–600 | Branded retail, stronger film |

| Multi-layer (5+) | 90–150 | 1200–2200 | 400–1200 | Barrier films, high-capacity lines |

This specification table demonstrates how screw size and layer count scale output and film properties, guiding Durban buyers to match extruder capacity with their intended bag-making throughput. After understanding technical benefits, buyers often seek reliable suppliers and delivery terms.

For transactional needs, buyers in Durban can evaluate machines and support from established manufacturers such as Kingdom Machinery Co., Ltd., which supplies a range of plastic bag making and blown film extrusion equipment. Suppliers with dedicated R&D teams, one-stop customization services, fast delivery windows (standard machines often shipped within 15–30 days with samples available in as little as five days), and 24-hour online after-sales support can shorten time-to-production and lower integration risk. When sourcing equipment, request final inspection records, warranty terms such as two-year warranty coverage on timer switches where applicable, and clarity on spare-part logistics to ensure steady production in South Africa.

Blown film extrusion involves melting polymer in an extruder, forcing it through an annular die, inflating the melt into a bubble, cooling the bubble with air rings, collapsing it through nip rollers, and winding the layflat film onto rolls for downstream converting. This process yields uniform film gauge and allows co-extrusion for multilayer structures that target strength, sealing and barrier properties simultaneously. Benefits include reduced raw material usage per bag due to low gauge variability, improved mechanical properties from biaxial orientation, and flexibility to incorporate recycled or specialty resins for sustainability. Key control variables include screw speed, die gap and cooling rate, which together influence film clarity, tensile strength and sealability.

Understanding process steps and benefits helps manufacturers specify extruder features that directly impact downstream bag quality and print performance, which in turn affects brand appearance and material costs.

Durban buyers can access monolayer, co-extrusion and multi-layer blown film extruders that vary by throughput, layer count and automation features, with each class serving different production profiles from small runs to continuous high-volume lines. Monolayer extruders suit small converters needing simplicity and low capital, while co-extrusion units offer three or more layers for enhanced performance and recycled-content incorporation. High-capacity multi-layer machines support continuous production for large-volume retailers and industrial packaging. Lead time and installation considerations matter: choose vendors who provide commissioning, trial runs and local technical assistance to minimize ramp-up time.

When evaluating models, compare output (kg/h), layflat width, melt-blown die capability and the supplier’s commissioning support to ensure the extruder integrates cleanly with existing bag making and printing equipment.

Flexo printing machines for plastic bags in South Africa are available as off-line or in-line units that enable high-quality branding directly on film or on finished bags, improving perceived value and supporting marketing requirements. Flexo integrates into bag production either in-line with extrusion and bag making for continuous production or as an off-line process applied to pre-formed film or bags; in-line printing reduces handling and registration issues but requires synchronized line speeds. Local availability depends on supplier networks and service arrangements, so prioritize machines with accurate color registration, quick plate changes and proven print stability on polymer films. Choosing the right flexo configuration affects lead time for new designs and per-unit print cost, influencing the viability of short runs and frequent artwork changes.

Below are practical benefits and considerations when selecting flexo machines in Durban.

These points highlight why manufacturers weigh tradeoffs between flexibility, speed and cost when specifying flexo solutions for local bag production.

Flexo printing machines apply ink via flexible plates to create sharp, repeatable graphics on polymer films, enabling consistent brand presentation across bag runs. The process allows variable color counts, fine halftones and relatively fast setup when plates and color separations are prepared correctly, making flexo ideal for both retail branding and regulatory printing. In-line flexo reduces handling and can lower overall per-unit cost for high-volume runs, but off-line flexo offers flexibility for shorter runs and sharper color control for specialty jobs. Plate-making lead times and color-matching processes are crucial operational considerations that affect turnaround and inventory planning.

Good print integration improves finished bag value and reduces rework; manufacturers should request test prints on target film grades to validate ink adhesion and curing profiles before full-scale production begins.

Multi-color flexo printing machines range from simple two-color in-line units to full four-color or more presses with UV or solvent drying options, and each configuration affects setup complexity and running speeds. Two-color presses are cost-effective for logos and basic branding, while four-color (CMYK) setups enable photographic-quality images and greater design flexibility at the expense of higher capital and plate costs. Higher color counts increase makeready time and require stricter registration control, so choose multi-color options based on order mix—frequent small runs favor simpler setups, while steady high-volume contracts justify complex presses. Consider consumables availability and maintenance support locally when selecting multi-color configurations.

Selecting the appropriate color capability is a balance between desired print quality, throughput requirements and total cost of ownership, which includes plate costs, ink consumption and downtime for color changes.

Recycling machines supplied to Durban complement bag production by turning post-industrial or post-consumer scrap into regrind or pellets, with common equipment including granulators, washing lines, extruders and water-cooling pelletizers. Integrating recycling reduces raw material costs and supports compliance with environmental targets by enabling closed-loop use of rejected film and trimming waste. Water-cooling recycling machines are commonly used when pellet temperature control is critical to pellet quality and downstream processing performance. Suppliers often offer modular systems that match recycling capacity to the main extrusion line so that recycled content ratios can be adjusted based on product specs and supply of scrap material.

Below is an overview of recycling workflow components and how they link to blown film and bag making operations.

| Recycling Component | Function | Benefit |

|---|---|---|

| Granulator | Shreds scrap into flakes | Enables uniform feedstock for washing |

| Washing Line | Removes contaminants | Improves pellet quality and mechanical properties |

| Extrusion & Pelletizer | Re-extrudes and forms pellets | Produces reusable resin for film/extrusion |

This workflow demonstrates how recycling machines transform process scrap into a controllable feedstock that can be reintroduced to blown film lines, reducing virgin resin use and lowering material costs.

For buyers seeking supplier capabilities, look for partners who provide commissioning, testing devices and R&D support to validate recycled blends. Suppliers that advertise competitive pricing through large-scale production, have internal R&D labs and offer 24-hour online after-sales support can accelerate integration of recycling equipment into a Durban production facility while minimizing technical risk.

Water cooling plastic recycling machines stabilize extruded melt by passing strands through a controlled water bath or cooling trough before pelletizing, which reduces melt temperature quickly and improves pellet roundness and bulk density. The process chain typically runs shredding, washing, extrusion, water cooling and pelletizing; controlled cooling lowers thermal degradation and dust generation compared with air cooling, producing pellets with more consistent melt-flow properties. Water management—filtration and wastewater handling—is an operational consideration to maintain sustainable plant operation and meet local environmental standards. Properly cooled pellets feed more reliably into blown film extruders and improve film homogeneity and downstream bag quality.

Water cooling thus plays a direct role in producing consistent recycled pellets, enabling higher recycled-content formulations without sacrificing process stability.

When evaluating recycling machine suppliers for Durban operations, prioritize firms that demonstrate clear after-sales support, spare-part availability and testing capabilities rather than relying only on price. Leading suppliers provide commissioning, demonstrated performance data, and reference processes that show how recycled pellets perform in blown film and bag making lines. Buyers should request demonstrations, sample pellets processed under representative conditions and transparent warranty and spare-parts policies. Avoid selecting vendors who cannot provide installation support or evidence of quality control procedures during production.

Demanding these supplier capabilities reduces integration risk and ensures recycled material meets the mechanical and visual requirements of finished bags, which is essential for brand consistency and regulatory compliance.

Machine costs in Durban vary widely based on automation, capacity, printing integration and multilayer extrusion capability; typical price bands fall into entry-level, mid-range and high-end categories that reflect increasing throughput and feature sets. Key cost drivers include automation level (full PLC and servo systems increase price), print integration (in-line flexo raises capital and complexity), multi-layer co-extrusion capability and supplier support such as final inspection, spare parts and warranty coverage. Operational costs—energy, maintenance, consumables and downtime—also affect total cost of ownership and should factor into procurement decisions. Below is a structured approach to pricing tiers, cost drivers and a checklist for obtaining tailored quotes.

Common pricing factors to evaluate include:

Buyers should request detailed quotes that separate machine price from shipping, installation and commissioning, and consider suppliers that offer clear lead times and spare-part policies to avoid hidden costs.

| Price Tier | Typical Features | Key Cost Drivers |

|---|---|---|

| Entry-level | Basic monolayer extruder + manual bag maker | Simplicity, lower automation |

| Mid-range | PLC control, in-line bag maker, 2-color print | Automation, print integration |

| High-end | Multi-layer extruder, multi-color flexo, high throughput | Co-extrusion, high-capacity components |

This pricing breakdown helps set realistic expectations and supports ROI calculations based on production targets, scrap rates and operational expenses. For precise pricing, contact suppliers for tailored quotes and ask for sample lead times and warranty details.

For tailored procurement, Plastic Bag Machine South Africa and recognized manufacturers such as Kingdom Machinery Co., Ltd. list value propositions relevant to Durban buyers: rigorous final inspection during production with defective rates controlled between 1% and 3%, two-year warranty on timer switches, dedicated R&D and engineering teams, and one-stop customization from concept to mass production. These supplier attributes—combined with competitive pricing via large-scale production and fast delivery windows—can materially shorten time-to-market. Contact Plastic Bag Machine South Africa to request specifications, compare lead times, and obtain a tailored quote that factors installation and after-sales support into the total cost.

Automatic bag making machines in South Africa span price ranges that reflect capacity and features: entry-level automatic units aimed at small producers are comparatively affordable, mid-range systems with PLC control and modest printing capability sit in the middle, and high-end automated lines with co-extrusion extrusion and multi-color flexo are the most expensive. Lead times and shipping can add materially to landed cost, and buyers should factor installation, training and spare parts into the procurement budget. Exact prices depend on configuration; asking for line-item quotes and comparing total cost of ownership over a 3–5 year horizon yields the most meaningful comparison. Ensure quotes include commissioning, acceptance testing and after-sales response commitments.

To minimize procurement risk, request vendor-provided production benchmarks and final inspection records that demonstrate achievable throughput and quality metrics under conditions similar to your Durban facility.

Higher capacity machines require larger screws, stronger drives and more robust cooling and winding systems, which increase capital expenditure but lower unit production cost through economies of scale. Additional automation—such as servo drives, automatic splicing and recipe-based PLC control—reduces labor costs and scrap but raises upfront price and spare-part complexity. In-line printing and multi-layer co-extrusion add both capex and maintenance tasks, but they enable higher-value products and reduce upstream supply dependencies. Calculate breakeven by comparing annualized capital cost plus operating expenses against expected revenue per bag at forecasted volumes to determine realistic ROI timelines.

A simple ROI thought process pairs machine throughput (bags/day) with margin per bag, then divides net annual contribution into the total acquisition and commissioning cost to estimate payback months and years.

Starting a plastic bag manufacturing business in Durban requires site selection with adequate utilities (power, water, waste handling), choosing the right production line configuration (extrusion + printing + bag making), sourcing raw materials and arranging for installation, staff training and quality control procedures. Begin with a clear product mix—T-shirt carriers, shopping bags, garbage bags or protective cushioning—and size equipment to expected order volumes with some buffer for growth. Factor in recycling and water-cooling equipment early if your business plan includes recycled content, because these systems affect material sourcing and process flow. Secure supplier commitments for commissioning, spare parts and training to accelerate production ramp-up and reduce early-stage downtime.

Operational planning and regulatory compliance in KwaZulu-Natal are essential, so schedule test runs, quality acceptance and staff certification with the equipment supplier before full-scale launches.

A practical setup sequence starts with site assessments for power capacity, water supply and waste handling, followed by line layout planning that places extrusion, printing, recycling and bag forming in logical flow to minimize material handling. Next, procure equipment matched to target capacity, schedule delivery and on-site installation, and plan commissioning runs with supplier technicians to validate production parameters. Concurrently recruit and train operators and maintenance staff on standard operating procedures, preventive maintenance and safety. Finally, run pilot production batches to refine machine parameters, incoming material quality checks and quality control protocols before full commercial supply.

Scheduling supplier installation and training during delivery planning ensures quicker ramp-up and fewer early production interruptions.

Buyers should expect and demand clear after-sales services such as warranty coverage for key components, ready availability of spare parts, remote troubleshooting and timely on-site technical assistance, as well as operator training and preventive maintenance programs. Reputable suppliers differentiate by offering documented final inspection during production, R&D and engineering support for custom configurations, and online support capabilities for rapid troubleshooting. When selecting a supplier, request service-level agreements that specify response times, key covered items and spare-part lead times to align expectations and protect production continuity. These service commitments reduce operational risk and help maintain consistent product quality for Durban customers.

Plastic Bag Machine South Africa and established manufacturers advertise one-stop services, internal R&D labs and 24-hour online after-sales support; make these considerations part of procurement evaluations and include them in vendor scorecards when comparing proposals.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.