Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

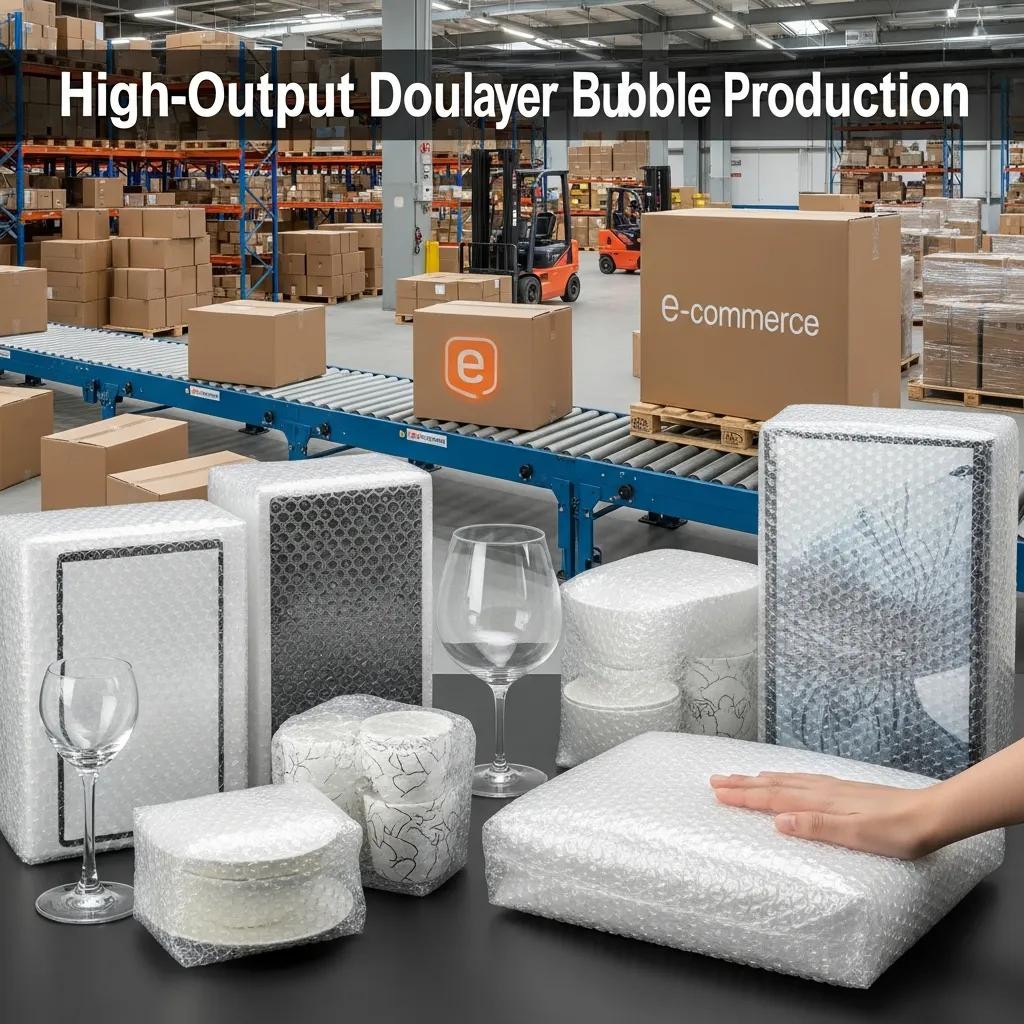

High-output double layer bubble film production refers to continuous blown-film extrusion systems that form two bonded layers of air bubble film for cushioning and packaging, delivering higher throughput and lower cost per square metre than single-layer alternatives. This guide explains how double layer bubble film machines work, why two-layer construction improves cushioning and puncture resistance, and how to match machine specifications—such as output capacity, film width, and material compatibility—to production goals. Readers will learn the core components and step-by-step production process, the efficiency and quality advantages of high-output systems, relevant technical specifications, and how bubble film production serves South African packaging industries. Practical operating and maintenance best practices are included to support continuous 24/7 production and minimise downtime. The article also outlines purchasing considerations and the value propositions offered by specialist suppliers to help procurement teams and operations managers evaluate bubble film extrusion machinery for e-commerce, industrial packaging, and local manufacturing.

A double layer bubble film machine is a blown film extrusion system that co-extrudes or laminates two polymer layers around an inflated bubble to create bonded, air-cushioning film with consistent bubble geometry and enhanced mechanical properties. The mechanism combines molten polymer extrusion, bubble inflation through a die/former, air-ring cooling to stabilise bubble shape, and lamination or nesting of a second layer to deliver improved puncture resistance and cushioning performance. The value is a finished roll that balances high throughput with consistent bubble size and film thickness, reducing material waste and improving pack integrity. Understanding these mechanics helps operators choose machine features—such as screw design, die head precision, and PLC controls—that directly influence capacity, film uniformity, and energy efficiency. Below, the core machine components and a step-by-step production workflow explain how these elements interact to produce reliable double layer bubble film.

Double layer bubble film extruders comprise modular components that each influence throughput, film quality, and process stability: extruder(s), precision die head and forming ring, air ring/cooling system, nip/lamination station (if co-extruded or nested), winding unit with tension control, and a PLC control panel for automation. The extruder screw and barrel determine melt homogeneity and throughput; a fully matched screw geometry lowers shear and improves output. The die head and forming ring control bubble inflation and symmetry, directly affecting bubble consistency and final film strength. The air ring and cooling system stabilise the bubble surface temperature, which impacts film clarity and adhesion between layers. The winding unit and tension controls determine roll quality and repeatability for downstream conversion. Each component forms a meronymic relationship to the system: extruder → provides melt; die head → shapes bubble; air ring → cools and stabilises; winding unit → finishes the product; and PLC → coordinates all subsystems for 24/7 operation.

The production process starts with material feed and melt preparation, progresses through bubble forming and cooling, and finishes with lamination (if applicable) and winding into finished rolls for distribution.

Raw LDPE or blends (including recycled LDPE) are dried and fed to the extruder, where controlled temperature profiles and screw speed produce a uniform melt; this melt is then forced through the die head to form a tubular film.

Air inflation and the air ring set bubble diameter and thickness, while controlled cooling and nip settings stabilise the film and enable bonding between layers for double-layer constructions.

The intricate process of forming a double-layer film involves precise control over cooling and lamination, a concept further elaborated by early research into blown film extrusion.

Double Layer Blown Film Extrusion Process

Blown film is extruded as a continuous tube which is air cooled, collapsed, and wound onto a roll as a double layer of film. Such film, if heat sealed and perforated, makes a roll of bags. There are many factors that affect blown film extrusion. Therefore, using expert system to evaluate blown film extrusion processes becomes an attractive subject.

Expert system for blown film extrusion, 1991

Winding tension management and roll handling complete the process to ensure consistent roll density and minimal defects for automated packaging lines.

Continuous monitoring via PLC reduces downtime and enables stable 24/7 production, which is essential for maintaining high output and predictable unit costs.

Manufacturer / supplier of plastic bag production equipment including blown film machines, plastic bag manufacturing machines, flexo printing machines, plastic recycling machines, and bubble film machines. Double Layers Air Bubble Film Machine — continuous 24/7 operation; processes LDPE and recycled LDPE; available in various widths and power options.

High-output double layer bubble film production delivers improved throughput, lower cost per unit area, and superior product performance through two-layer construction that increases puncture resistance and cushioning. The reason this configuration works is that the second layer distributes impact forces and secures bubble geometry, while high-output machine design lowers energy and labour cost per kilogram of film produced. For buyers and operations teams, the practical benefits include faster ROI through higher kg/h capacity, more consistent roll quality for automated packaging, and greater flexibility in processing blends of virgin and recycled LDPE. The combination of efficiency and performance enables manufacturers to supply e-commerce and industrial markets with robust protective packaging while optimising production economics.

Different benefit categories and metrics are useful when comparing machine choices and understanding expected returns.

This EAV table quantifies typical efficiency and cost advantages across machine classes to help procurement teams evaluate ROI and per-unit costs.

| Machine Class | Attribute | Value |

|---|---|---|

| High-output double layer | Typical output capacity | 60–120 kg/h |

| High-output double layer | Cost per m² (relative) | Lower vs single-layer systems |

| Conventional single-layer | Typical output capacity | 20–60 kg/h |

The table highlights that double layer, high-output machines commonly exceed conventional single-layer throughput and deliver lower relative cost per square metre. These efficiency gains translate to measurable savings in energy consumption, labour hours, and material handling for continuous production environments.

High-output systems reduce per-unit costs through higher continuous throughput, improved line uptime, and reduced manual intervention; these factors together lower energy and labour cost per kilogram and per square metre of film produced. Matching machine capacity to demand reduces overproduction and inventory carrying costs, while consistent roll quality reduces scrap and rework from downstream conversion. Energy efficiency also improves with optimized screw and barrel designs that deliver throughput with reduced specific energy consumption per kg. Example calculations often show a meaningful reduction in cost per roll when moving from lower-speed single-layer lines to high-output double-layer extruders due to compound savings across materials, power, and labour.

Double layer bubble film improves mechanical performance by combining layers that resist puncture, distribute impact, and maintain bubble geometry across the roll, resulting in better protection for fragile goods and more consistent performance on automated packing lines. Two-layer construction allows tailoring of each layer—one for strength and one for surface properties—so the finished film achieves both toughness and good printability or sealing characteristics. This architecture also reduces the incidence of bubble collapse and improves edge strength during handling and automated bagging, translating to fewer damaged shipments and higher customer satisfaction.

The combination of efficiency and performance makes double layer films an attractive option for e-commerce fulfilment centres and manufacturers seeking predictable protective packaging performance.

Technical specifications centre on output capacity (kg/h), film width range, bubble diameter, screw and die dimensions, and power consumption. These parameters determine how a machine fits production targets and plant electrical/infrastructure constraints. For example, higher screw diameters and optimized L/D ratios increase throughput but require more power and larger floor space; wider die heads enable broader film widths but may reduce achievable line speed for a given output target. Material compatibility—specifically LDPE and recycled LDPE blends—also affects required melt temperature profiles and filtration strategies. Optional features such as flexo printing integration, laminators, and advanced PLC controls expand product capabilities but add to lead times and capital cost.

Buyers should evaluate specs in the context of expected daily throughput, product mix, and energy availability to select the best-fit machine configuration.

| Model | Output Capacity | Film Width Range |

|---|---|---|

| Compact two-layer | 60–80 kg/h | 600–1000 mm |

| Standard high-output | 80–120 kg/h | 800–1600 mm |

| Heavy-duty high-output | 120+ kg/h | 1200–2000 mm |

This comparison provides a quick view of how machine classes vary in output capacity and width, which supports matching a production line to market demand. Consideration of power and footprint should follow once the capacity and width envelope are established.

For commercial enquiries and specific machine configurations, consider available product classes and service scope described by specialist suppliers. Manufacturer / supplier of plastic bag production equipment including blown film machines, plastic bag manufacturing machines, flexo printing machines, plastic recycling machines, and bubble film machines. Double Layers Air Bubble Film Machine — continuous 24/7 operation; processes LDPE and recycled LDPE; available in various widths and power options.

Output capacity, film width, and power consumption form the triad of selection criteria that influence production planning and operational cost-effectiveness. Output capacity aligns with demand forecasts and inventory strategies; oversizing capacity increases capital cost while undersizing risks missed orders. Film width determines how many finished packaged units per roll are possible and affects downstream conversion efficiency. Power consumption affects operating expenses and may require electrical upgrades for higher-capacity machines. Balancing these parameters requires scenario modelling: match expected kg/h to daily production goals, calculate energy cost per kg, and evaluate how width impacts roll change frequency and labour.

LDPE and blends with recycled LDPE are commonly processed on double layer bubble film machines, but recycled content introduces variability that must be managed through pre-processing, filtration, and process control adjustments. Best practices include consistent pellet sizing, robust filtration to remove contaminants, moisture control, and stabiliser/additive strategies to compensate for melt index variability. Higher recycled content may require slower screw speeds, modified temperature profiles, and tighter monitoring of melt pressure to maintain bubble stability and interlayer adhesion. When implemented correctly, recycled LDPE usage lowers material costs and supports sustainability goals without sacrificing film performance for many cushioning applications.

Double layer bubble film production supports South African packaging needs across e-commerce, electronics protection, appliance shipping, and industrial component cushioning by supplying locally produced protective materials that reduce lead times and shipping costs. Local production diminishes reliance on imported rolls, enabling faster response to demand spikes from Johannesburg, Cape Town, Gqeberha, and Soweto distribution hubs. The flexibility to process recycled LDPE aligns with growing sustainability preferences in the local market while supporting cost-sensitive packaging operations. Manufacturers can configure film width and bubble size to match common regional product dimensions and shipping practices, improving material utilisation and eliminating excess packaging waste.

This local production capability strengthens supply chain resilience and supports just-in-time packing strategies for retailers and manufacturers.

Double layer bubble film is particularly useful for e-commerce parcel cushioning, protection of electronics and glassware, interleaving between stacked products, and as a protective wrap for appliances and industrial components. Different applications require different bubble diameters and film thicknesses; smaller bubbles and thinner films suit lightweight items and void fill, while larger bubbles and thicker two-layer films protect heavier, fragile goods. Choosing the correct specification reduces product damage during transit and improves packing speed on automated lines where bubble consistency and roll handling are critical.

Current market trends in South Africa show rising e-commerce volumes, increased interest in recycled-material packaging, and demand for local suppliers who can deliver quickly to minimise supply chain delays. These drivers elevate the importance of flexible production lines that can run 24/7 and process LDPE blends with recycled content. Local manufacturers value short delivery lead times and reliable after-sales support to keep lines running and meet fluctuating order patterns. Suppliers that can offer custom widths and rapid machine delivery enable domestic converters and packers to respond to market shifts without prolonged procurement cycles.

Choosing an equipment supplier involves evaluating quality assurance, customization capabilities, delivery timelines, and after-sales service to reduce buyer risk and ensure long-term production stability. Plastic Bag Machine South Africa positions itself as a lead-generation partner and supplier with offerings that align to buyer concerns: simple operation, reliable performance, easy maintenance, and timely after-sales service. Their stated advantages include rigorous inspection and warranty commitments that reduce procurement risk and support continuous operation. Presenting these value propositions alongside technical guidance helps buyers make decisions that prioritise uptime and predictable production economics.

Plastic Bag Machine South Africa highlights several explicit commitments that address common buyer risks: 100 percent final inspection to ensure machines leave the factory tested, a two-year warranty on timer switches to protect critical control components, and a strong R&D and engineering team that supports customization and problem solving. These elements collectively reduce commissioning issues and shorten ramp-up time on site. Timely after-sales support and spare-parts availability are essential for continuous 24/7 production, and formal inspection plus warranty coverage mitigates early-life failure risks that can disrupt high-output lines.

Emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service. For buyers seeking one-stop solutions from innovation to mass production, these supplier capabilities align with expectations for reliable equipment procurement.

Plastic Bag Machine South Africa states standard delivery windows and customization services designed to meet local market urgency: standard machines are delivered within 25–30 days, while customised units require 30–60 days depending on specification complexity. The company’s R&D and engineering team can modify screw profiles, die configurations, and automation packages to match customer demands, which helps local manufacturers avoid long import lead times that can stall production ramp-up. Fast delivery and on-the-ground after-sales responsiveness reduce downtime risk and support rapid scaling for seasonal demand or new product launches.

Operational discipline and preventive maintenance are essential to sustain high-output 24/7 production while minimising unplanned downtime. Best practices combine consistent raw-material quality controls, standardised start-up and shut-down procedures, tight process parameter control for melt temperature and bubble stability, and scheduled preventive maintenance for screws, die lips, air rings, and winding systems. Operators should rely on PLC monitoring for early alarms and maintain spare-part inventories for critical wear items. A structured maintenance schedule reduces the probability of catastrophic failures and supports predictable production planning.

The following operational checklists, maintenance table, and troubleshooting guidance provide practical steps to keep machines running at designed capacity.

Introductory maintenance schedule table below helps planners set spare-part levels and service intervals.

| Maintenance Task | Frequency | Typical Time Required |

|---|---|---|

| Visual inspection and cleaning (die lip, filters) | Daily | 15–30 minutes |

| Winding unit check and tension calibration | Weekly | 30–60 minutes |

| Screw and barrel inspection | Monthly | 2–4 hours |

Operators should implement standardised start-up checklists that verify material feed, screw and barrel temperatures, and PLC parameter baselines before inflation begins; controlled ramp-up of screw speed and inflation ratio stabilises bubble formation and prevents collapse. Typical parameter ranges for stable bubbles depend on material MFI and screw design; monitoring melt pressure and surface appearance helps detect inconsistencies early. For troubleshooting, common quick fixes include adjusting inflation air volume, re-aligning die lips, cleaning filters, and balancing winding tension; when issues persist, consult engineering support for deeper inspection of screw wear or die distortion.

Preventive maintenance supports uninterrupted high-output production by scheduling part replacements before failure and stocking critical spares such as screws, die lips, filters, and timer switches. A recommended spare-parts inventory prioritises high-wear items that could halt production if unavailable; items like timer switches and critical sensors should be stocked given their operational importance. Monthly and quarterly inspections of the extruder, die head, and winding systems should include dimensional checks, alignment verification, and lubrication schedules. Professional service intervals for in-depth inspections and reconditioning depend on operating hours and material abrasiveness but should be planned proactively.

Emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service. Manufacturer / supplier of plastic bag production equipment including blown film machines, plastic bag manufacturing machines, flexo printing machines, plastic recycling machines, and bubble film machines. Double Layers Air Bubble Film Machine — continuous 24/7 operation; processes LDPE and recycled LDPE; available in various widths and power options.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.