Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Plastic bag making machines for sale in East London provide manufacturers and converters with the equipment needed to produce retail, shopping and specialty bags locally, reducing lead times and improving material control. This guide explains the common machine types, supporting film production technologies, printing options, and recycling equipment relevant to South African operations, with a brief commercial note that Plastic Bag Machine South Africa acts as a regional distributor and lead generation partner for established manufacturers. Many East London businesses face supply-chain delays and high import costs; choosing the right combination of blown film extrusion, automatic bag makers and complementary flexo printers solves those problems by enabling in-house film production, consistent quality, and faster turnaround. In the sections that follow we define available machine classes, explain how blown film extrusion integrates with bag lines, show where local buyers can source flexo printers, review recycling equipment and pricing drivers, and outline why Plastic Bag Machine South Africa is a practical partner for local installations. Practical checklists, comparison tables, and step-by-step procurement guidance will help you shortlist equipment for specific production needs and prepare accurate quote requests.

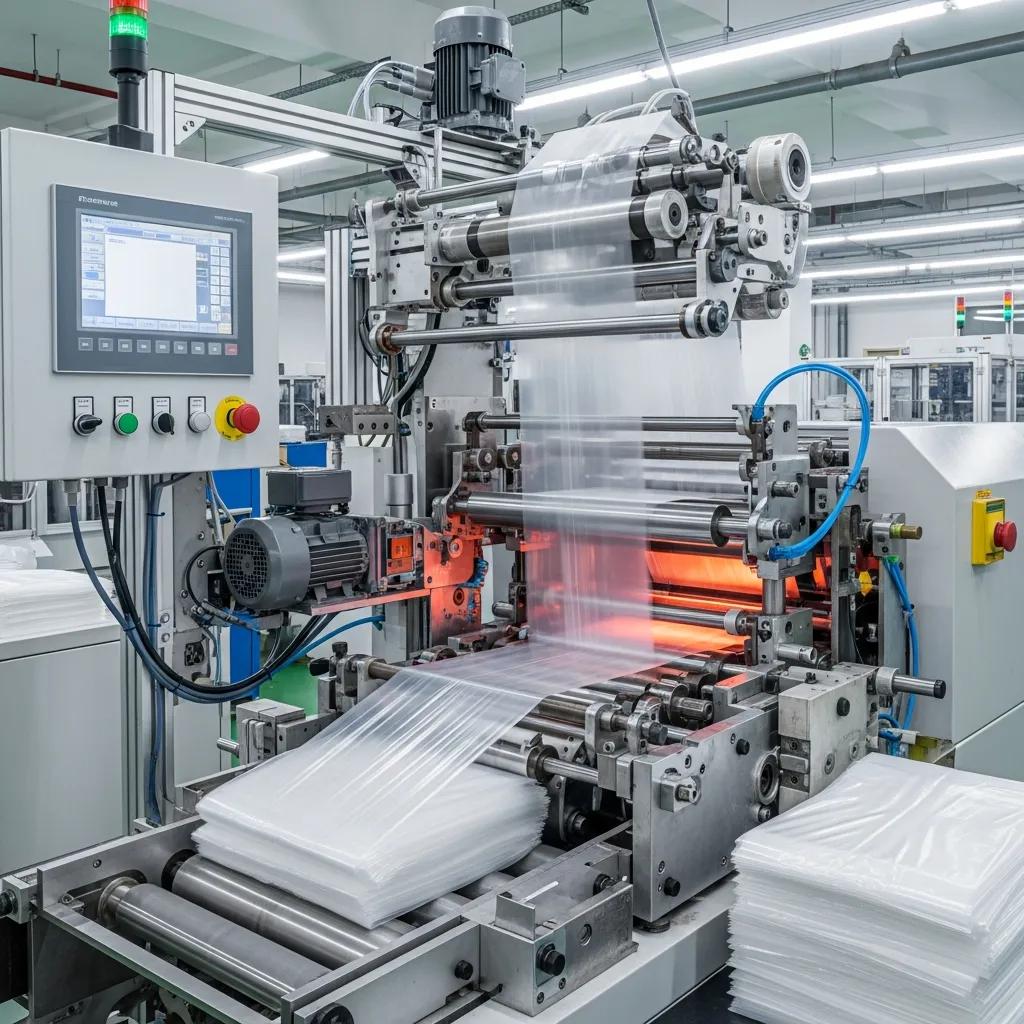

Plastic bag making machines available to East London manufacturers include specialised automatic lines for T-shirt bags, shopping bags, flat/punched bags and machines designed for biodegradable film; each machine class converts film into finished bags through sealing, cutting and optional printing or gusseting operations. These systems vary by automation level, throughput, and material compatibility, and selecting the right class depends on bag type, target production speed and chosen film (HDPE, LDPE, LLDPE, PLA or PBAT). Below we summarise principal machine types with their typical use-cases, then provide a comparison table to contrast capacity, automation and indicative price ranges for planning. After the comparison, we explore automatic T-shirt machines and biodegradable equipment in greater depth to highlight operational considerations and material handling differences.

This table compares common bag-making machine types, their core attributes and indicative value for East London producers.

| Machine Type | Key Attributes | Typical Value / Use |

|---|---|---|

| Automatic T-shirt Bag Making Machine | High-speed sealing and punching, compatible with HDPE/LDPE, PLC control | Ideal for retail and high-volume shopping bag production |

| Shopping Bag Making Machine (handle/patch) | Handles formation, reinforced seals, moderate speed | Suited for branded retail shopping bags and heavier films |

| Bottom Sealing Machine / Flat Bag Machine | Continuous sealing and cutting for flat bags and garbage bags | Efficient for general-purpose bags and refuse sacks |

| Biodegradable Bag Making Machine | Temperature-controlled extrusion and adjusted screw design for PLA/PBAT | Enables eco-branded bags and regulatory compliance for compostables |

These machine classes form the basis for most bag operations and help narrow technical conversations with suppliers. The next subsections detail how automatic T-shirt machines improve throughput and what features biodegradable bag equipment requires.

Automatic T-shirt bag making machines automate punching, sealing and stacking to achieve consistent high throughput, often measured in bags per minute, and significantly reduce manual labour requirements. These machines use PLC controls and servo-driven mechanisms to synchronise film feed, cutting and handle formation, which improves repeatability and reduces scrap rates; this automation also shortens changeover times between different bag sizes. Typical capacities depend on model and film thickness, but the key operational gains are reduced labour cost per bag and higher uptime through predictive maintenance routines built into modern control systems. Understanding these performance metrics helps manufacturers match a machine to production targets and downstream packing processes, which leads naturally to evaluating biodegradable-capable equipment and material handling concerns.

Biodegradable bag making equipment is engineered to process materials such as PLA, PBAT and other compostable resins by offering refined temperature control, tailored screw geometry and gentle melt handling to preserve polymer integrity. Machines intended for biodegradable films often include adjustable extrusion profiles and controlled cooling to avoid degradation while achieving target film strength and sealability; operators must be aware of different processing windows compared with HDPE or LDPE. Certification and labelling considerations also influence machine selection because consistent film thickness and seal performance are essential for achieving compostability standards at bag level. With these processing constraints in mind, manufacturers should specify material compatibility, thermal stability features and recommended production speeds when requesting quotes to ensure equipment meets eco-branding requirements.

Blown film extrusion produces the primary film feedstock that bag making machines convert into finished bags; an extruder melts polymer resin and forms a tubular film via a die and cooling ring, producing continuous bubble film that is collapsed and wound for downstream bag conversion. The core mechanism—melt extrusion, bubble inflation and controlled cooling—dictates film properties such as thickness, clarity and mechanical strength, which in turn determine bag performance for specific applications. Choosing between single-layer and multi-layer extruders depends on required barrier properties, mechanical strength and material cost optimization, with multi-layer systems enabling layer-by-layer formulations that combine HDPE/LDPE with barrier or tie layers. The table below compares typical multi-layer blown film extruder variants to guide selection for East London production lines and explain integration points with bag-making equipment.

| Extruder Variant | Typical Film Width | Thickness Range | Material Compatibility |

|---|---|---|---|

| 3-layer blown film extruder | 600–1200 mm | 10–80 microns | HDPE/LDPE blends, cost-effective films |

| 5-layer blown film extruder | 800–1600 mm | 8–120 microns | Improved barrier options, mix of recycled/resin layers |

| 7-layer blown film extruder | 1000–2200 mm | 5–200 microns | Advanced barrier and strength, co-extruded functional layers |

Understanding the extruder variant and film characteristics informs bag maker selection and final product specification. Next we address the benefits of multi-layer film and how extrusion lines integrate with bag-making production.

Multi-layer blown film extrusion machines combine different polymers in discrete layers to deliver tailored mechanical and barrier properties while optimising raw material costs through strategic layer composition. By placing a barrier layer between structural layers, manufacturers can achieve oxygen or aroma barriers without resorting to costly monolayer specialty resins, and by incorporating recycled content in core layers, they reduce material costs while maintaining surface quality. These layered structures also enable targeted performance—such as puncture resistance on the outside layer and sealability on the inner layer—supporting applications from retail bags to industrial packaging. Choosing layer counts involves trade-offs among equipment cost, film performance and complexity of operation, which leads naturally to considerations for synchronising extrusion output with bag-making throughput.

Integration between blown film extrusion and bag making lines typically involves coordinated winding, in-line printing or offline printing, and matched speed control so that film output aligns with bag maker demand and quality control systems verify thickness and print registration. Practical layouts include unwind stands feeding automatic bag makers or inline reel-to-reel arrangements with flexo printing units placed between extrusion and bag conversion, requiring compatible tension control and communication between PLC systems. Quality assurance benefits from online thickness gauges, vision systems for registration, and sample inspection points to ensure the extruder’s output meets bag specifications; these integration features reduce waste and enable just-in-time bag production. With integration considerations covered, buyers should next evaluate flexo printing options for branding and high-quality graphics.

Flexo printing machines for film and bag printing are available from regional distributors and specialist suppliers that serve packaging converters across South Africa, offering equipment ranging from basic 2-color units to advanced inline 6-color systems with varnish and lamination options. Flexo printing applies fast-drying inks via flexible plates and is valued for high-speed production, good color consistency and compatibility with a range of substrates, making it a common choice for branded shopping bags and promotional products. When sourcing flexo equipment in or near East London, buyer criteria should include color capacity, registration accuracy, substrate handling and available service support—this checklist helps you evaluate options before requesting demonstrations or quotations. After the checklist we summarise how flexo printing enhances branding and then review specific capabilities available locally.

Consider this buyer checklist to evaluate flexo printing options before supplier engagement.

This checklist helps prioritize features during supplier discussions and leads into a look at how flexo printing affects brand presentation.

Flexo printing machines improve brand presentation by enabling high-speed, repeatable color printing directly onto film or bag films, producing crisp logos, text and spot colors that elevate perceived product value. The flexo process accommodates a wide range of inks, including water-based and solvent systems, allowing converters to choose formulations compatible with substrates and regulatory requirements, while plate-making technologies ensure accurate artwork reproduction. Operationally, flexo printing affects run planning and changeovers—collecting artwork, making plates and setting registration take time—so efficient prepress workflows and skilled operators are important to maintain productivity. Understanding these trade-offs helps brand owners balance print quality, speed and cost when selecting a flexo supplier.

Flexo printing machines available to East London converters typically range from simple 2-color units for basic branding to full 6-color lines with varnish, lamination options and in-line die-cutting for finished bag production. Higher-color-count machines enable photographic-quality gradients and complex artwork, while varnish and lamination improve surface durability and perceived finish; each additional capability increases capital and operating costs, so buyers should match capabilities to market positioning. Local suppliers can often demonstrate samples or run trial jobs to prove registration and color fidelity on your chosen substrate, which is a recommended step before committing to purchase. After assessing printing, manufacturers should consider recycling equipment to close material loops and reduce raw material expenses.

Plastic recycling machines used in bag production operations include industrial shredders, granulators and pelletizers, each converting waste film into regrind, flakes or pellets suitable for reuse in blown film lines or as secondary content. The recycling process chain—shredding, washing/drying, granulation and pelletization—determines output quality and suitability for reintroduction into extrusion, and equipment capacity, automation level and ancillary systems drive price differences. Below is a comparison table showing typical recycling equipment types, capacity ranges and indicative price brackets to help East London buyers budget for closed-loop initiatives and evaluate ROI on recycled-content programs.

| Recycling Equipment | Typical Capacity (kg/hr) | Input / Output | Indicative Price Range |

|---|---|---|---|

| Industrial Shredder | 100–1000 kg/hr | Waste film → flakes | Mid-range capital cost |

| Granulator | 50–800 kg/hr | Flakes → uniform granules | Variable by rotor size |

| Pelletizer | 100–1000 kg/hr | Granules → pellets for extrusion | Higher capital cost due to added processing |

Investing in recycling equipment affects material cost and sustainability credentials, so purchasers must weigh capital expenditure against potential savings from reprocessed resin. The following subsections explain the sustainability benefits and the primary cost drivers that influence equipment pricing.

Plastic recycling machines enable manufacturers to convert scrap, offcuts and post-consumer film into regrind or pellets that lower raw material purchase volumes and reduce waste sent to landfill, supporting circular manufacturing models. The typical process—shredding to reduce size, washing to remove contaminants, and pelletizing to produce uniform feedstock—yields outputs that can be blended into blown film extrusion, decreasing virgin resin usage and stabilising material supply. Operational benefits include reduced raw material costs, improved control over input material streams and stronger sustainability messaging for brands; however, quality control and contamination management are essential to ensure recycled material meets film and sealability requirements. By integrating recycling into the production flow, converters gain both environmental and economic advantages that feed back into bag-making line specifications.

Key factors influencing recycling equipment price include processing capacity, automation level, inclusion of washing and drying systems, and the complexity of end-product polishing or pelletizing stages, with brand and after-sales support further affecting total cost of ownership. Higher-capacity units with automated feeding, advanced contaminant sorting and integrated water-treatment systems command premium prices but deliver lower per-kg processing costs and greater uptime. Buyers should also account for ancillary expenses such as installation, training, spare parts and energy consumption when calculating ROI. Evaluating these cost drivers alongside desired recycled-content targets helps determine the right equipment scale for East London operations.

Plastic Bag Machine South Africa serves as a local distributor and lead generation partner representing Kingdom Machinery Co., Ltd., offering a one-stop selection of plastic bag making machines including automatic T-shirt bag machines, shopping bag machines, bottom sealing machines, biodegradable bag machines, blown film extrusion lines, flexo printing units and plastic recycling equipment. The distributor emphasises simple operation, reliable performance, easy maintenance and timely after-sales service while providing customization options and a competitive pricing model supported by multiple production lines and global installations. For East London manufacturers seeking managed procurement and local support, this partner brings access to varied equipment types plus logistics and technical coordination relevant to installation and commissioning. The next subsections list the company’s UVPs in context and explain how local after-sales support benefits on-site manufacturers.

Plastic Bag Machine South Africa highlights several practical value propositions: straightforward machine operation that reduces training time, designs that simplify maintenance to lower downtime, and a strong R&D orientation enabling one-stop customization for specific production requirements. The distributor emphasises competitive pricing and fast delivery windows for samples and bulk orders, along with claims of significant global installations that underline production capacity and manufacturing scale. These UVPs translate into buyer benefits such as faster ramp-up of new production lines, predictable lead times for sample and bulk delivery, and the ability to request tailored machine configurations. Prospective buyers should request detailed technical proposals to confirm how these UVPs map to their specific production targets, which leads into how local service and after-sales support operate.

Local support and after-sales service reduce downtime through faster response times for spare parts, installation, commissioning and operator training, and they allow manufacturers to adopt service-level agreements that match production-critical schedules. On-site technician availability and remote support options help maintain uptime while structured training programs shorten the learning curve for new operators, increasing effective throughput. Regular maintenance contracts and access to replacement parts locally mean lower logistical delays compared with fully imported support models, and these factors together protect production targets and cash flow. Understanding the expected service scope and escalation procedures before purchase ensures alignment between supplier commitments and factory operational expectations.

Requesting a quote for plastic bag making machines is a structured process that starts with defining production targets, bag specifications and material choices, and ends with a tailored recommendation, quotation, lead time estimate and after-sales plan from the distributor or manufacturer. Providing clear inputs such as desired bag type, film material (HDPE/LDPE/PLA/PBAT), target output (bags per minute or kg/hr), print requirements and budget constraints enables more accurate proposals and reduces clarification rounds. Below is a numbered step-by-step process to request a customised quote and prepare for supplier evaluation, followed by guidance on what information to have ready to speed up responses.

This procurement sequence helps buyers gather comparable proposals and streamlines technical conversations; the next subsection provides a checklist of buyer inputs and expected turnaround times as part of the quote process.

To request a customised quote, prepare a concise specification package outlining bag dimensions, film type, target output rate and any required extras such as inline printing, perforation or stacking, then submit these requirements to your chosen distributor for assessment. The supplier will typically recommend machine configurations, provide formal quotations, state lead times and outline deposit and delivery terms; asking for sample lead times and bulk production windows is useful to validate scheduling expectations. For East London buyers, clarifying installation needs and local support expectations when requesting a quote ensures the proposal includes commissioning and training where necessary. Having this information ready shortens the quoting cycle and provides a clear baseline for comparing offers from multiple suppliers.

A concise FAQ set addresses typical buyer concerns such as pricing ranges, machine compatibility with biodegradable materials, local servicing options and lead times, and implementing such questions on your supplier page increases transparency and speeds procurement decisions. Common PAA-style questions include queries on machine capacity per shift, the feasibility of processing recycled feedstock, print registration tolerances for flexo units and the availability of local spare parts, and presenting these clearly helps both buyers and suppliers align expectations. Implementing an FAQPage-like format for public listings or RFPs improves featured-snippet eligibility and reduces repetitive enquiries during the quote phase. With clear FAQs and prepared specifications, East London manufacturers can efficiently progress from interest to installation with minimal delays.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.