Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Polokwane manufacturers and converters looking to start or scale plastic bag production need clear, local guidance on machine families, process flow, and purchasing considerations. This guide explains the core machine categories used in Polokwane — blown film extrusion, flexo printing and converting, and recycling equipment — and shows how each contributes to reliable bag making and product quality. Many small and medium producers struggle with matching production targets to machine throughput and with ensuring local service and spare parts; this article offers practical steps to calculate demand, compare equipment, and prepare a specification checklist. You will learn what machine types are available locally, where to source reliable suppliers in Limpopo, how blown film extrusion and flexo printing operate in a production line, how recycling machines enable sustainable feedstock, and exactly which specifications and after-sales arrangements to prioritise when buying. Throughout, target terms like plastic bag machine Polokwane, blown film extrusion, flexo printing machine, and plastic recycling machine are used to help you find appropriate equipment and plan a conversion-ready production line.

Plastic bag making in Polokwane relies on three main machine families that cover film production, printing/decoration, and conversion plus on-site recycling. Blown film extrusion machines produce tubular film rolls that are the raw substrate for most bags; flexo printing machines add branding and graphics to film before conversion; converting and bag-making lines (cutters, sealers, and winders) convert printed or plain film into finished bags. Recycling granulators and pelletizers reprocess production scrap and post-industrial waste into regrind or pellets that can be blended back into extrusion to reduce costs and waste. Understanding these families helps buyers map production flow from resin to finished bags and select complementary equipment that fits capacity, product type, and sustainability goals.

This quick comparison helps match machine families to intended outputs and throughput ranges:

| Machine Family | Typical Output (bags/min or kg/h) | Typical Use-case |

|---|---|---|

| Blown film extrusion machines | 1–40 kg/h film output (depends on die and layers) | Produce layflat tubular film for grocery, carrier and bin liners |

| Flexo printing machines | 10–200 m/min web speed (printer-dependent) | Apply multi-colour logos and branding to film rolls before converting |

| Bag converting & sealing lines | 20–400 bags/min (varies by bag type) | Cut, seal and form carrier, T-shirt, and flat bags from film rolls |

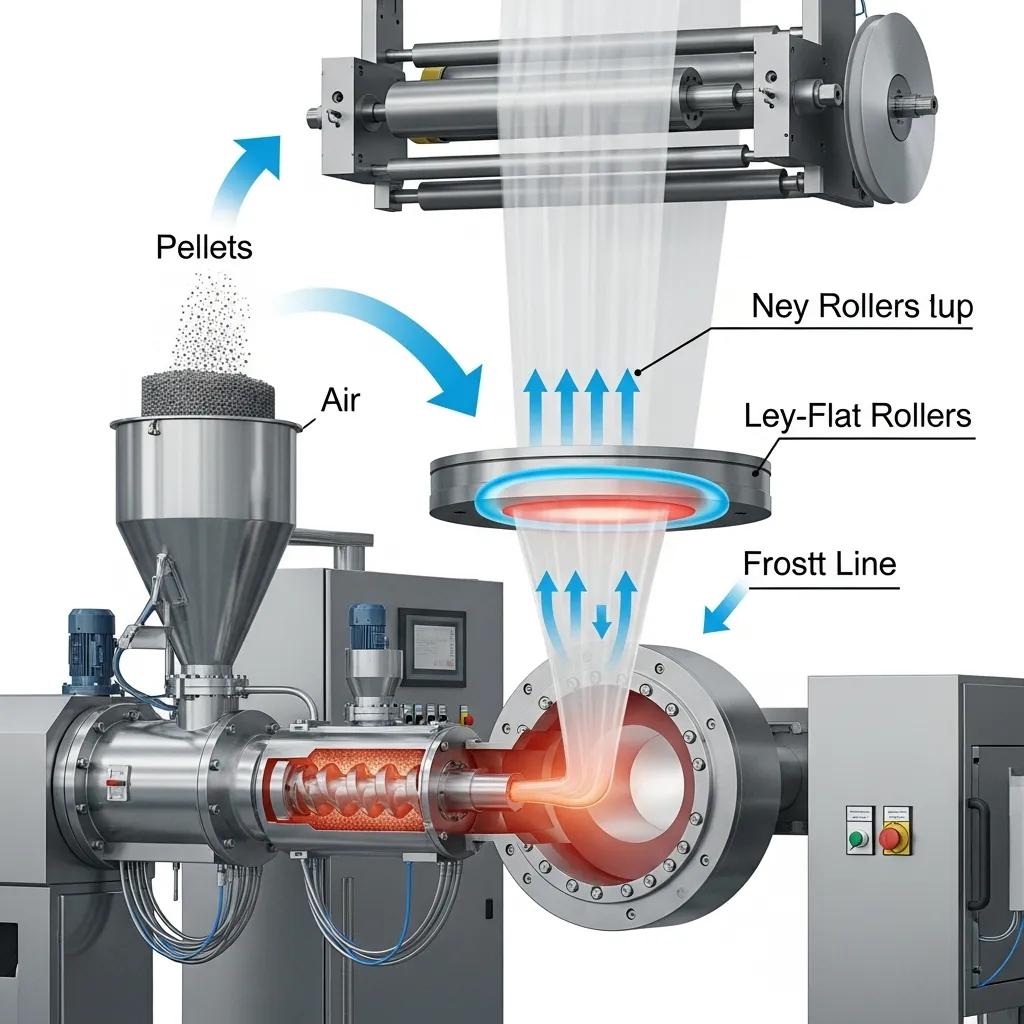

Blown film extrusion machines create continuous tubular film by melting polymer resin, forcing it through a circular die, and inflating a bubble that sets film thickness and width. The extruder unit, die head and cooling ring are meronym components that together determine bubble stability and gauge control; a winder or rewind station collects film into rolls for downstream converting. Converters include slitters, heat-sealers, and cutter units that form bag shapes and add handles or gussets, while printing units—often flexo stations—apply inks and varnishes before final finishing. Knowing where each machine sits in the line clarifies investments: extrusion upstream, printing midline, and converting/finishing downstream, enabling buyers to plan utilities and floor layout accordingly.

These functional roles set up the next comparison between blown film and flexo printing technologies and when operators should integrate them into a single line.

Blown film extrusion focuses on producing the polymer film substrate, controlling film gauge, layflat width and layer structure, while flexo printing focuses on surface decoration and colour registration on that film. Extrusion advantages include flexibility in material blends and multilayer coextrusion for barrier or strength; flexo printing advantages include high-speed, low-cost per impression and the ability to print variable artwork at scale. When to choose combined lines versus standalone machines depends on volume: integrated extruder-plus-printer lines reduce handling and enable inline quality control for high-volume producers, whereas standalone extrusion feeding off-line printing and converting offers flexibility for smaller runs and varied print jobs. Understanding these trade-offs guides decisions about plant layout and capital allocation.

After mapping machine families and functions, many buyers will want supplier quotes, specifications and demonstrations to match machines to production targets; local equipment dealers and distributors in Limpopo can provide tailored proposals, technical datasheets and on-site demonstrations to help validate throughput and compatibility.

Finding reliable suppliers and service partners in Limpopo requires verification of technical competence, spare-parts support, and logistics capability for installation and commissioning. A credible supplier should provide technical datasheets, references or case studies, on-site commissioning and training options, and clear spare-parts lead times. Assessing local service capability and warranty terms reduces downtime risk, and checking whether suppliers offer demonstration runs or test film production helps confirm machine performance before purchase. Considering transport, crane or forklift requirements, and local electrical and civil preparations ensures installations go smoothly in Polokwane’s facilities.

When evaluating prospective suppliers, use the following verification and inquiry checklist to prioritise credible partners:

Buyers should approach manufacturers, authorised distributors, and experienced resellers that specialise in packaging machinery and can support integration across extrusion, printing and converting. Prioritise suppliers who demonstrate systems knowledge across film extrusion lines, flexo printing stations and rewinding/finishing equipment and who can coordinate delivery and installation logistics in Limpopo. Ask suppliers for training plans, a spare-parts list with typical lead times, and details of any offered maintenance contracts or local technicians, as these elements influence total cost of ownership and uptime. Evaluating suppliers on these criteria helps ensure you select partners able to support production ramp-up and long-term reliability.

Start by calculating your production targets (bags per day/week), then translate those targets into required film output, machine throughput and shift patterns. Specify film characteristics—material type (LDPE, HDPE, LLDPE), gauge range and layflat width—and match them to extrusion die size and extruder throughput. Confirm utility requirements (power, compressed air) and floor space including access for maintenance, and evaluate modularity for future upgrades such as adding flexo printing stations or a pelletizer. Comparing total cost of ownership rather than headline price ensures decisions account for energy consumption, spare parts, training and expected ROI.

This selection framework sets up the technical explanation of blown film extrusion next, where we describe process steps and practical operating considerations relevant to Polokwane operations.

Blown film extrusion is a process that melts polymer resin and converts it into a tubular film through an extruder and circular die, with controlled cooling and winding to produce rollstock suitable for bag making. The process works by forcing molten polymer through the die, inflating the extruded tube into a bubble whose diameter and cooling rate determine film width and gauge consistency. This method yields films with balanced mechanical properties and allows multilayer coextrusion for strength or barrier layers, making it versatile for carrier bags, bin liners and other formats. Precise control of extrusion parameters and bubble stability results in consistent film thickness and lower scrap rates, which directly affects production yield and material cost.

A concise process list clarifies the core steps operators will encounter in production:

These steps show where quality control checkpoints belong — specifically at viscosity control, bubble stability, and winding tension — which prepares the line for integration with printing and converting equipment.

For buyers seeking machine options, local suppliers in Polokwane can advise on appropriate extruder sizes, die configurations and multilayer capability to match your product mix and budget; request machine specifications and compatibility options directly from suppliers to confirm electrical, automation and footprint requirements.

In practice, blown film extrusion requires careful setup of screw speed, melt temperature and die lip adjustments to control film gauge and mechanical properties relevant to bag performance. Operators monitor bubble stability, frost line height and thickness variation using inline gauges and process control systems to maintain consistent output and reduce waste. Local conditions such as ambient humidity and temperature can influence cooling and bubble behaviour, so climate-aware adjustments and enclosure or air-conditioning of the line may be necessary in some facilities. Quality control checks at regular intervals—thickness sampling, tensile tests and visual inspection—ensure the film meets conversion requirements for sealing and printing.

Maintaining these controls ensures consistent film quality that downstream flexo printing and converting equipment can reliably process, which is examined in the following subsection.

Blown film extrusion offers versatility in film thickness and layer structure, enabling manufacturers to produce films tailored for grocery, retail and bin-liner applications with variable strength and barrier properties. The process is cost-effective for medium to high-volume production due to efficient material usage and relatively low capital per unit of throughput when optimised for continuous operation. Blown film lines also support coextrusion to combine virgin and recycled material or to add barrier layers without separate lamination, improving production flexibility and reducing steps in the value chain. These operational benefits make blown film extrusion a practical foundation for Polokwane plastic bag factories focused on scalable, adaptable production.

Understanding flexo printing benefits next will show how printed film increases market value and how to combine printing with extrusion.

Flexo printing machines use flexible plates and fast-drying inks to transfer artwork onto flexible films at high speeds, providing a balance of print quality and production efficiency suitable for bag printing. Flexo excels on polyethylene films used for bags because plates and low-viscosity inks adapt well to film properties and allow quick changeovers for different print runs. Advantages include relatively low per-piece printing cost at scale, relatively fast setup for repeat jobs, and good colour consistency when proper colour management and pre-press procedures are used. Choosing flexo makes sense when customers require branding, regulatory text or multi-colour designs that add perceived value to the finished bag.

Key practical benefits are:

Flexo printing uses plates mounted on rotating cylinders, an anilox roller to meter ink, and quick-drying solvent or water-based inks formulated for film adhesion; plate-making and ink formulation are core pre-press tasks that determine final image quality. Suitable substrates include blown or cast polyethylene films commonly used for carrier and retail bags, and print quality depends on surface treatment (corona or plasma) to improve ink wetting. Typical applications include full-colour retail bags, promotional packaging, and printed film for branded carrier or grocery bags; printers tune anilox line screens, plate durometers and drying stations to achieve required dot gain and colour density. Good pre-press workflows and inline registration control enable consistent results across long rolls and multiple production shifts.

Local converters in Polokwane can improve print quality through controlled pre-press checks, colour management protocols and finishing options like lamination or varnish to increase durability and tactile appeal. Regular maintenance of anilox rollers, plate cleaning and register calibration prevents common defects such as streaking or poor colour density, and consistent substrate treatment ensures reliable ink adhesion. When integrating flexo with converting lines, coordinate print drying capacity and rewind tension to avoid set-off or blocking on stacked rolls. These operational practices help manufacturers deliver printed bags that meet brand expectations and withstand handling in distribution.

Recycling machines—granulators, wash lines and pelletizers—convert production scrap, trimming waste and post-industrial material into regrind or pellets suitable for blending with virgin resin, enabling closed-loop or partial-recycle production strategies. These machines work by size reduction, contaminant removal and sometimes extrusion-pelletizing to create usable feedstock with controlled melt-flow characteristics. Integrating recycling equipment reduces feedstock costs, diverts waste from landfill and supports sustainability claims when managed with appropriate quality controls and traceability. Proper contamination control and testing are essential to ensure recycled content meets mechanical property targets and regulatory or customer requirements.

Introductory note: This table shows common recycling equipment, their typical input materials and the usable output types they produce for reintegration into extrusion processes.

| Recycling Equipment | Input Material | Output Type / Usage |

|---|---|---|

| Granulator | Trim scrap, edge trim | Regrind flakes for direct blending or feed into pelletizer |

| Wash line | Contaminated film scrap | Clean flakes suitable for pelletizing or direct reuse |

| Pelletizer / Extruder | Clean regrind or mixed flake | Recycled pellets blended with virgin resin for extrusion |

In Polokwane facilities, recycling equipment often functions either as an on-site pre-processor for high-volume converters or as a local service provided by recycling partners that accept post-industrial scrap. Granulators reduce film and cuttings to uniform flakes, while wash lines remove contaminants that would otherwise affect melt properties, and pelletizers standardise feedstock for extrusion. By establishing contamination control, labelling and material segregation protocols, converters can ensure recycled output meets melt-flow and strength specifications for targeted bag grades. These practices enable producers to plan blending ratios and maintain consistent product quality when using recycled content.

Practical integration typically places granulation and initial separation close to the converting line to minimise transport of scrap, followed by washing and pelletizing either on-site or at a nearby facility depending on scale. Blending ratios of recycled pellets with virgin resin commonly begin conservatively (e.g., low percentages) and increase as quality control validates performance; melt-flow index and tensile testing guide acceptable ratios for strength-critical applications. Process adjustments—higher melt temperatures, modified screw profiles or gentle cooling—may be required to accommodate regrind variability. Establish a quality assurance loop to sample recycled batches, record provenance and track performance to ensure long-term consistency.

When purchasing, prioritise specifications that directly impact your production targets: machine output rate, film width and gauge range, power consumption, footprint and automation level. Assess total cost of ownership including energy use, spare parts availability, expected downtime and training support; local after-sales service and spare parts lead times in Limpopo materially affect uptime and should influence supplier selection. Verify compatibility with recycled feedstock if you plan to blend regrind, and confirm electrical, compressed air and civil requirements before committing to a purchase. A thorough procurement checklist ensures you order machines aligned with product types, production scale and local serviceability.

Use this checklist-style list to make final purchase comparisons more objective and snippet-friendly:

After evaluating technical specs, compare these specifications across shortlisted machines using the table below to fast-track decision-making.

Introductory note: The table below summarises purchasing specifications buyers should compare and the typical expected ranges to use as a reference when requesting quotes.

| Specification | Consideration | Expected Range / Note |

|---|---|---|

| Film width | Required layflat width for bag types | 200–1200 mm typical (varies by application) |

| Film gauge | Thickness range needed for product strength | 10–120 microns common for LDPE/LLDPE bags |

| Output rate | Material throughput aligned to demand | 20–400 bags/min or 1–40 kg/h film as applicable |

| Power & Utilities | Electrical phase, kW and air requirements | Confirm site-specific supply and safety margins |

Request machine datasheets that specify mechanical output (bags/min or kg/h), film gauge tolerance, layer count for extruders, print station colour capacity and automation features like PLC control and servo-driven components. Ask for information on consumables and recommended spare inventories—belts, heater bands, anilox rollers—and include training packages in the procurement negotiation. Translate your production targets into required runtimes and maintenance intervals to calculate spare parts and service contract needs. These specification checks reduce ambiguity in proposals and support apples-to-apples comparisons among suppliers.

Local service arrangements should cover installation, commissioning, operator training and preventive maintenance schedules, and buyers should confirm average spare-parts lead times and options for expedited delivery. Establishing a planned spare-parts inventory—critical wear items and fast-moving spares—reduces potential downtime, and negotiating a service-level agreement or maintenance contract provides predictable support for production-critical lines. Train in-house technicians during commissioning to handle first-line troubleshooting while relying on supplier technicians for complex repairs. Prioritising these after-sales factors ensures resilient production capability in Polokwane and helps protect your investment over time.

For buyers ready to proceed with quotations or demonstrations, contact suppliers directly through their official sales channels to request specifications, machine availability and demonstration options; keeping these procurement conversations focused on specifications and service will maximise the value of supplier proposals.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.