Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

Flexible LDPE blown film machines are specialized film extrusion systems that convert low-density polyethylene resin into continuous tubing or lay-flat film for flexible packaging applications. This guide explains how blown film extrusion works, compares machine types from monolayer lines to multilayer co-extrusion plants, and describes the material properties that make LDPE a go-to polymer for retail bags, food contact films and industrial liners. Procurement and specification decisions hinge on technical variables—screw diameter, die head design, blow-up ratio, and auxiliary units such as corona treaters—so this article helps buyers translate product needs into machine specifications and ROI estimates. Readers will also find comparison tables, actionable lists for decision-making, and a concise overview of supplier capabilities available from Plastic Bag Machine South Africa (operating as Kingdom Machinery Co., Ltd.), presented as a practical example of customization and support options. By the end you will understand process mechanics, machine selection criteria, cost drivers and how downstream converting and recycling systems integrate into a robust flexible packaging line.

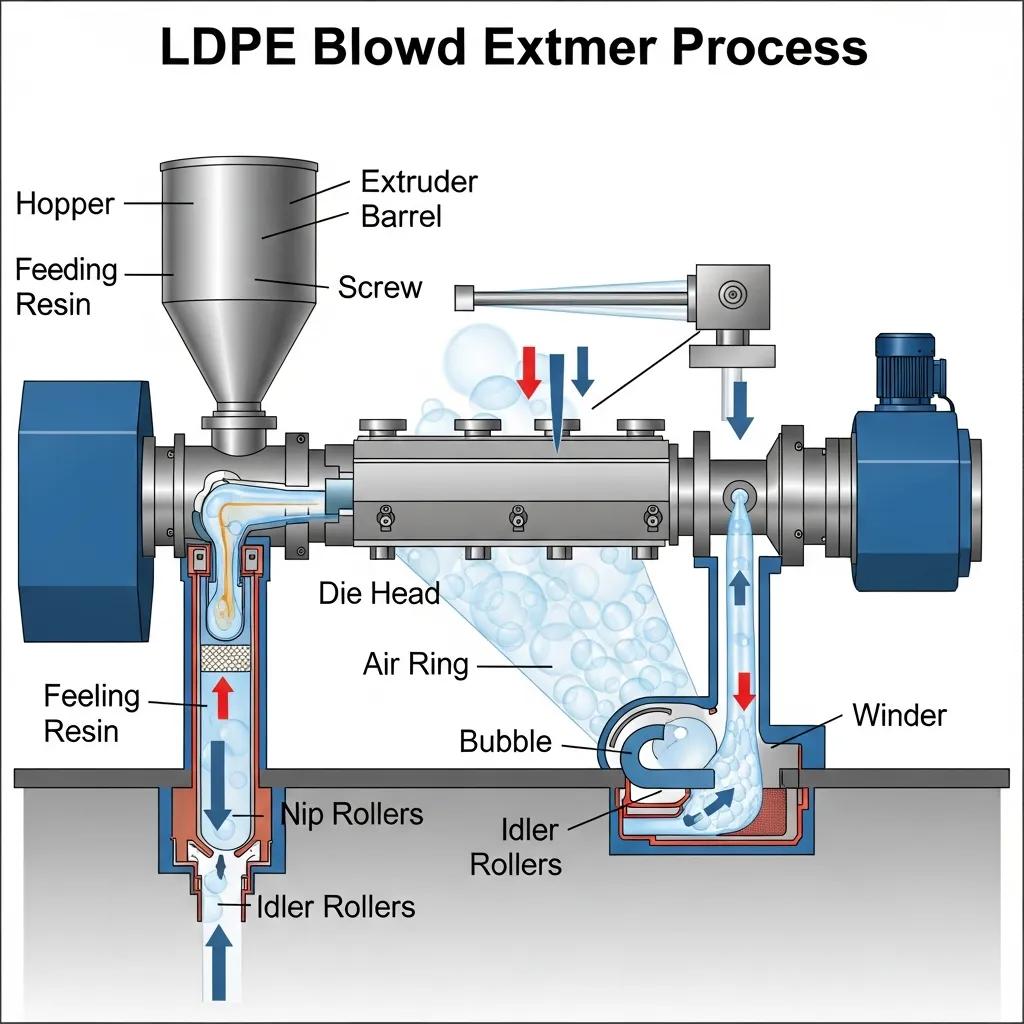

The LDPE blown film extrusion process melts polymer resin and extrudes it through an annular die to form a continuous tubular bubble that is cooled, collapsed and wound into rolls; this produces flexible packaging films with controllable thickness, width and mechanical properties. Process variables such as melt temperature, screw speed, blow-up ratio and air ring cooling determine film orientation, gauge uniformity and surface characteristics, delivering specific benefits like improved clarity or enhanced tensile strength. Understanding these steps helps buyers specify extruder L/D ratios, die types and downstream equipment for target products. The following numbered list breaks the process into concise steps for quick reference and to support featured-snippet style clarity.

The blown film extrusion process can be summarized in clear operational steps:

These steps show the main control points for film quality. The next subsection explains how bubble mechanics and process parameters produce different film properties.

Blown film extrusion creates film properties through bubble expansion, cooling rate and drawing which control molecular orientation and film thickness distribution. When the melt is extruded and inflated, the blow-up ratio defines transverse orientation while nip and haul-off rates influence machine direction orientation, together determining tensile strength and elongation. Cooling at the frost line locks in crystallinity and optical properties: faster cooling favors clarity but may reduce toughness, while slower cooling increases crystallinity and rigidity. Practical adjustments—higher blow-up ratio for better impact resistance or slower haul-off for thicker gauges—allow manufacturers to tune film for shopping bags, shrink films or heavy-duty liners.

These mechanisms connect directly to the equipment choices discussed next, where extruder and die specifications determine the practical control range for those variables.

A typical LDPE blown film machine comprises an extruder (screw and barrel), annular die head, air ring cooling system, bubble cage/eddy stabiliser, haul-off and winder, and optional auxiliaries such as corona treaters and gravimetric dosing systems. The extruder screw diameter and L/D ratio set melt throughput and shear history, while die design (annular or rotary) influences melt distribution and gauge uniformity. Ancillary systems—air rings for even cooling, precise haul-off drives for consistent film draw-down, and corona treatment for surface energy—complete the production chain and enable downstream printing and conversion. Machine control systems and automation level determine repeatability and operator workload, so buyers should match component specification to intended film grade and production target.

Selecting appropriate components requires comparing expected throughput and film targets, which leads into machine type choices and co-extrusion options covered in the next major section.

Blown film machines vary from simple monolayer lines suitable for standard bags to multilayer co-extrusion systems designed for barrier, seal or printable films; high-speed lines and lab-scale extruders fill specific production niches. Machine selection depends on required film function, output (kg/hr), gauge range and budget, so comparing configurations and typical outputs helps align capital expenditure with product goals.

Intro to the machine-type comparison table: this table contrasts common blown film line categories so buyers can match product needs to machine capability.

| Machine Type | Key Attribute | Typical Value / Application |

|---|---|---|

| Monolayer blown film machine | Simplicity and lower capex | 50–300 kg/hr; retail bags, simple liners |

| 3-layer co-extrusion line | Functional layer control | 100–500 kg/hr; seal/barrier/printable films |

| High-speed blown film line | Throughput and efficiency | 300–1000+ kg/hr; large-volume retail film production |

| Lab-scale blown film extruder | R&D and sampling | 1–20 kg/hr; product development, trials |

This comparison clarifies trade-offs among simplicity, performance and throughput. The next subsection contrasts monolayer and multilayer approaches in more detail.

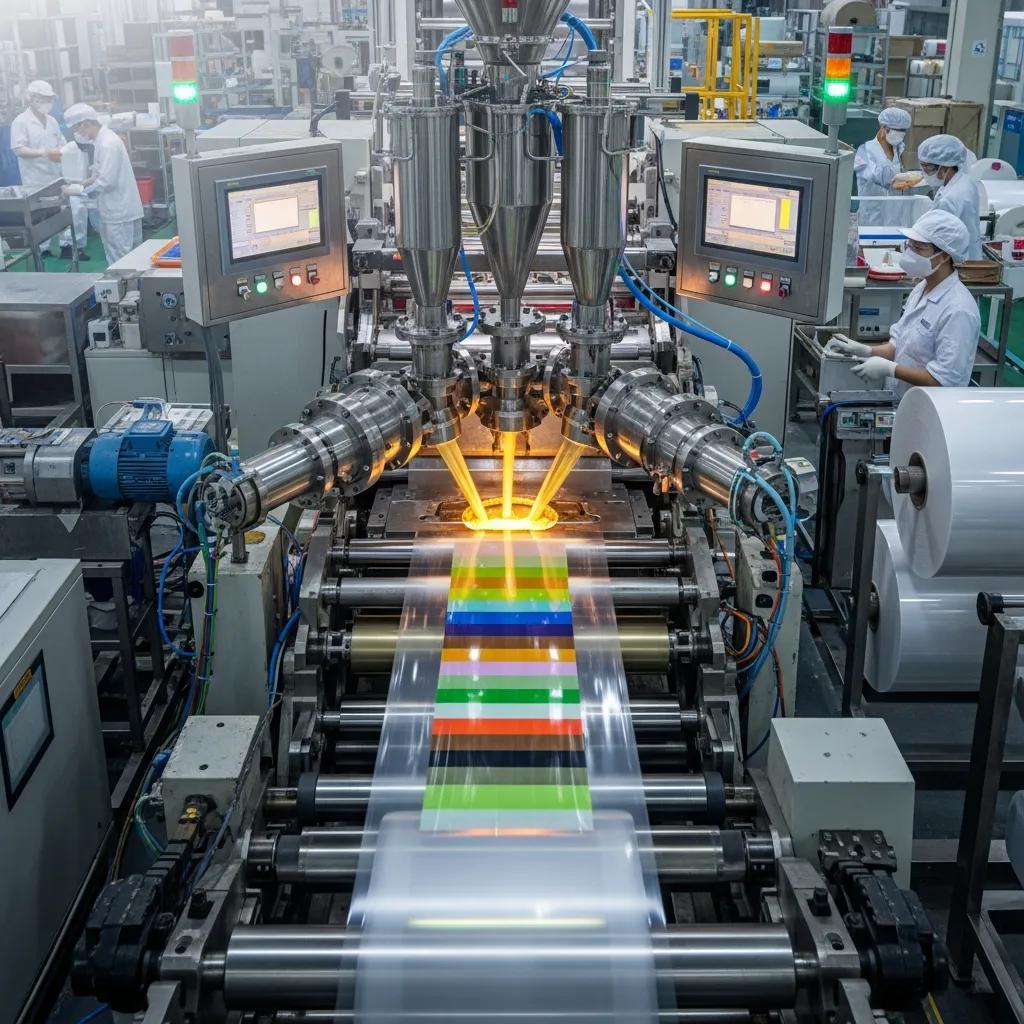

Monolayer lines extrude a single polymer composition, offering the simplest process, lower capital cost and straightforward recycling, which suits commodity bags and basic liners. Multilayer co-extrusion machines combine materials in distinct layers—typically sandwiching a core or barrier layer between sealant and printable surfaces—to provide tailored barrier properties, seal performance and printability without changing overall film thickness. The trade-offs include higher equipment complexity (multi-screw extruders, feedblocks or co-extrusion die heads), increased process control demand, and improved functionality that can reduce downstream processing. Choosing between them depends on product requirements: if barrier, seal or print quality is critical, co-extrusion generally outweighs the additional cost by enabling fewer later-stage treatments.

Understanding how layers function leads directly into the advantages multilayer designs bring to film performance, discussed in the next subsection.

Multilayer co-extrusion assigns functional roles to each layer—outer layers for printability and abrasion resistance, core layers for strength or barrier performance, and tie layers for adhesion between incompatible polymers—enabling films that balance cost and functionality. For example, combining an LDPE sealant layer with an LLDPE core improves sealability and puncture resistance while a thin barrier layer reduces oxygen transmission for food packaging. Co-extrusion also permits the targeted use of recyclate in non-critical layers to improve sustainability without compromising surface properties. Effective multilayer designs require precise melt flow balance, die engineering and gravimetric dosing to maintain consistent layer thickness and film performance.

These material and layer choices connect to the next section on LDPE properties and the practical applications that benefit from each multilayer strategy.

LDPE is a low-density polyethylene prized in blown film for its flexibility, good clarity, wide heat-seal range and ease of extrusion; these polymer-level attributes make LDPE suitable for films requiring soft hand, reliable heat sealing and decent optical performance. Compared with other polyethylenes, LDPE tends to offer higher elongation and better impact resistance but lower tensile strength and stiffness, so it is chosen where conformability and seal quality matter. The EAV-style table below compares LDPE, LLDPE and HDPE on core properties and typical packaging uses to guide material selection for specific products.

Intro to material comparison table: this table summarizes key material attributes and typical uses to help match polymer selection with product requirements.

| Polymer | Core Property | Typical Packaging Uses |

|---|---|---|

| LDPE | High flexibility, good sealability, clarity | Retail/shopping bags, food contact films, shrink applications |

| LLDPE | Higher tensile strength and puncture resistance | Stretch film blends, heavy-duty sacks, agricultural films |

| HDPE | Higher stiffness and opacity | Rigid liners, carrier bags with stiffer feel, industrial sacks |

This comparison shows why LDPE is often selected for consumer-facing, seal-critical flexible packaging. The next subsection lists specific product categories where LDPE blown films are commonly used.

LDPE blown films are widely used for retail and carrier bags, lay-flat tubing, food-contact films (fresh produce bags and bakery wraps), shrink films for packaging and thin-gauge bin liners that require flexibility and reliable seal performance. Typical film thickness ranges vary by application—shopping bags and lay-flat tubing often use 15–40 microns, food contact films may require tighter gauge control and clarity, while industrial liners use thicker gauges for durability. Printability and surface treatment compatibility determine whether outer layers need corona treatment, especially for branded retail packaging. Selecting the correct film gauge and machine configuration ensures the final product meets handling and shelf requirements.

Matching product specs to machine capability leads into a concise look at the polymer characteristics that make LDPE particularly suitable for these uses.

LDPE’s low crystallinity yields a soft, flexible film with high elongation and good impact resistance, which provides puncture tolerance and conformability to irregular loads. The polymer’s relatively low melting point and broad heat-seal window simplify processing on blown film lines and enable consistent seal strength across a range of converters and packaging machines. Optical properties can be excellent with appropriate cooling control, making LDPE suitable for clear packaging where product visibility matters. However, when higher stiffness, stronger tensile properties or superior barrier characteristics are required, formulators and machine specifiers often blend LDPE with LLDPE or add barrier layers in co-extrusion designs.

These material trade-offs inform customization choices and supplier conversations, which are the focus of the next company-specific section.

Plastic Bag Machine South Africa, operating as Kingdom Machinery Co., Ltd., specialises in manufacturing and supplying plastic bag production lines with a strong focus on Flexible LDPE Blown Film Machines for Packaging and related converting equipment. The company positions itself as a one-stop supplier offering customization, with dedicated R&D resources and in-house testing to match machine configurations to product requirements. Their operational capabilities include multiple production lines and a testing lab, and they emphasise quality control and specific warranty terms on selected components to support buyer assurance. The paragraph below briefly summarizes factual company differentiators that buyers should consider when evaluating suppliers.

Key factual capabilities and buyer-relevant assurances from the company:

These factual details indicate how the supplier’s production and testing infrastructure can shorten development cycles and reduce delivery risk, which leads into the next subsection that outlines specific customization choices buyers typically request.

Customization options commonly include layer configuration (monolayer up to multiple co-extruded layers), screw diameter choices to control throughput, optional auxiliaries such as corona treaters, automatic loaders, rotary die heads, and tailored winding systems for specific roll formats. Buyers should prioritise options that directly affect product performance—selecting co-extrusion capability when barrier or multi-function films are needed, or adding corona treatment for high-quality printing. Control systems and automation levels vary from semi-manual to fully automated PLC-based solutions, so specifying desired OEE targets and staffing constraints helps determine automation scope. Technical decisions should be driven by target film gauge, width, composition and downstream converting compatibility.

Kingdom Machinery communicates a structured quality approach including 100% final inspection during production to identify issues before shipment and a two-year warranty on specified components such as timer switches to provide component-level assurance. Their R&D and testing capacity—16 production lines and more than 30 testing devices—supports sample validation and process tuning prior to delivery, while reported fast sample and bulk delivery options reduce lead-time risk for pilots and production ramp-up. Global installation experience and a one-stop customization service help align machine configuration with buyer requirements and local converting workflows. These quality practices and delivery commitments aim to reduce commissioning time and ensure machines meet agreed performance targets.

Primary cost drivers for LDPE blown film equipment include machine specification (number of layers, screw size), auxiliary equipment (corona treaters, winders), automation level, and recurring operational costs such as energy consumption and material waste; understanding these elements is essential for ROI modelling. Capital expenditure correlates strongly with machine complexity—multilayer co-extrusion lines and high-speed units command higher capex but can deliver lower unit costs at scale. Operational cost elements like kWh/kg, material scrap rate and labour shift patterns determine per-kg production cost and should be included in any ROI calculation. The EAV table below presents key cost-driver components to structure a basic ROI analysis.

Intro to cost-driver table: use this table to identify and quantify components that should be included in ROI calculations.

| Cost Component | Attribute | Impact on ROI |

|---|---|---|

| Machine CapEx | Number of layers, screw diameter, automation | High — determines depreciation and financing cost |

| Energy Consumption | kW per hour and kW/kg throughput | Medium — affects running cost per kilogram |

| Material Cost | Price per kg of resin and scrap rate | High — dominates variable cost of production |

| Maintenance & Labour | Maintenance frequency, operator skill | Medium — affects uptime and OEE |

This structured view clarifies which inputs matter most in ROI models. The next subsection lists the primary factors that typically influence price and specification decisions.

Price is influenced primarily by the number of extruders/co-extrusion layers, die complexity and engineering precision, screw diameter and L/D ratio which set throughput capability, and the level of automation and auxiliary modules included. Additional price modifiers include the quality of control systems, surface treatment units like corona treaters, and enhanced winding or slitting systems for specific roll requirements. Supplier scale and production practices can also affect pricing—larger manufacturers with many production lines may offer more competitive unit prices through economies of scale. These variables should be ranked against expected production volumes to determine whether a higher initial investment will amortize through lower unit costs.

A simple ROI approach starts with estimated annual gross margin from film production minus annual operating costs, divided by the machine capex; expressed as: ROI (%) = (Annual Profit / CapEx) × 100. Required inputs include capex, expected annual throughput (kg), gross margin per kg (selling price minus material and energy costs), and annual fixed/variable operating costs (labour, maintenance, energy). Track KPIs such as OEE, scrap rate, energy per kg and throughput to refine the model and identify improvement opportunities. For practical decision-making, run sensitivity analyses on material price and downtime assumptions to understand payback periods under conservative and optimistic scenarios.

These actions bridge cost modelling and procurement lead times; supplier delivery performance can shorten ramp-up and improve effective ROI.

Flexible packaging production is rarely limited to blown film extrusion alone; downstream converting such as flexo printing, bag-making, slitting and recycling machines are essential to deliver finished products that meet branding, regulatory and functional requirements. Integrating these systems starts with matching web width, film tension control and surface treatment specifications between the extruder and downstream equipment to ensure print registration and reliable converting. Recycling machines that wash, shred and pelletize post-industrial or post-consumer film close material loops and can reduce virgin resin consumption when appropriate material quality control is applied. The list below summarizes how complementary equipment contributes to a full production ecosystem.

Bag making machines convert film into finished products by folding, sealing and cutting the web to produce formats such as carrier bags, flat bags and gusseted sacks; precise tension control and consistent film gauge are essential to avoid defects. Flexo printing machines add graphics and regulatory text, and rely on consistent surface energy—often achieved via corona treatment—for ink adhesion and print quality. Registration systems on printing presses require stable web path and minimal gauge variation, so extruder and winder choices directly affect print yield and scrap rates. Coordination between film production and converting teams reduces changeover time and improves first-pass yield.

Recycling machines—washing lines, shredders, extruders and pelletizers—process production scrap or post-consumer film into recyclate that can be reintroduced into blown film lines under controlled formulations. Closed-loop recycling reduces virgin resin consumption and material costs, but recyclate quality must be managed to avoid contamination and performance degradation; strategies include using recyclate in non-critical layers or blending with virgin resin. Equipment for sorting and washing increases upfront processing cost but enables higher-quality recyclate with predictable properties. Implementing recyclate requires coordination across film design, co-extrusion strategy and quality control to maintain product performance while improving sustainability.

This final technical linkage underscores how downstream and recycling equipment, combined with precise film specification, close the loop on efficient, functional flexible packaging production.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.