Plastic Bag Making Machines for Sale in Pretoria

Plastic Bag Making M

If you’re setting up a bag-production line in Randburg, this guide explains the machine types, key specifications, and local services that get production running quickly and profitably. You will learn which automatic plastic bag making machines suit different business scales, how blown film extrusion enhances film quality, and what to expect from flexo printing, pricing, financing, and after-sales support in Gauteng. Many manufacturers face choices about throughput, material compatibility (HDPE, LDPE, LLDPE or biodegradable blends), and integration with printing or recycling; this article addresses those decisions with practical guidelines. The guide also explains maintenance best practices and how to evaluate suppliers and service partners close to Johannesburg and Randburg. Read on for machine comparisons, structured specification tables, maintenance checklists, and concise buying guidance tailored for South African manufacturers and converters.

Plastic bag production lines in Randburg typically include distinct machine families designed for specific bag styles and throughput levels. Each machine type—T-shirt bag making machines, side sealing machines, shopping bag machines, garbage bag manufacturing machines and bio bag machines—uses a combination of sealing jaws, winders and cutting stations to convert film into finished bags at rates that range from low-volume starter lines to high-speed industrial output. Understanding these categories helps match production goals with capital and floor-space constraints while ensuring material compatibility with HDPE, LDPE, LLDPE or compostable resins. Below is a comparison table to clarify typical production ranges, footprint and common applications for each machine family; the table helps buyers quickly identify the right class of equipment for their facility.

| Machine Type | Typical Production Capacity | Material Compatibility |

|---|---|---|

| T-shirt bag making machine | 30–150 pcs/min | HDPE, LDPE, LLDPE |

| Side sealing bag making machine | 50–300 pcs/min | LDPE, LLDPE, biodegradable blends |

| Shopping bag machine | 40–200 pcs/min | HDPE, LDPE (printed film possible) |

| Garbage bag manufacturing machine | 100–600 pcs/min | LLDPE, HDPE, reinforced blends |

| Bio bag machine | 20–120 pcs/min | PLA blends, compostable resins |

This comparison highlights that machine selection depends primarily on throughput and material; higher-speed lines require more robust winding, stronger sealing jaws, and precise film handling. Selecting the correct family reduces waste and improves run-time efficiency, which leads into choosing the right machine for your scale and operations.

Matching machine families to business scale begins by defining target throughput, available floor space, and primary bag formats. Small start-ups often choose entry-level T-shirt or side-seal machines that balance lower capital cost with simple operation and limited staffing needs, producing tens to low hundreds of bags per minute. Medium-sized converters targeting retail shopping bags typically select mid-range shopping bag machines with in-line flexo print compatibility and moderate footprint, supporting higher margins through branded printing. Large manufacturers and contract packers usually invest in high-speed garbage bag manufacturing machines with reinforced sealing systems and automated winding to handle hundreds of pieces per minute. When planning a purchase, consider power requirements, operator training, and space for auxiliary equipment like a blown film extruder or flexo printing module to ensure smooth integration into a production line.

Biodegradable or bio bag machines are engineered to process compostable resins such as PLA blends and other biodegradable polymer formulations by adjusting extrusion and sealing temperature profiles and sometimes die geometry. These machines maintain consistent film temperature and controlled cooling to preserve mechanical properties while avoiding thermal degradation that can compromise seal integrity. Using biodegradable materials helps brands comply with evolving packaging regulations and meet consumer demand for sustainable options, but it also requires tighter quality control and possible third-party testing to verify compostability claims. For manufacturers, the incremental changes include calibrated sealing jaws, careful control of film thickness and tolerance checks—adaptations that ensure biodegradable bags perform reliably in retail and waste streams.

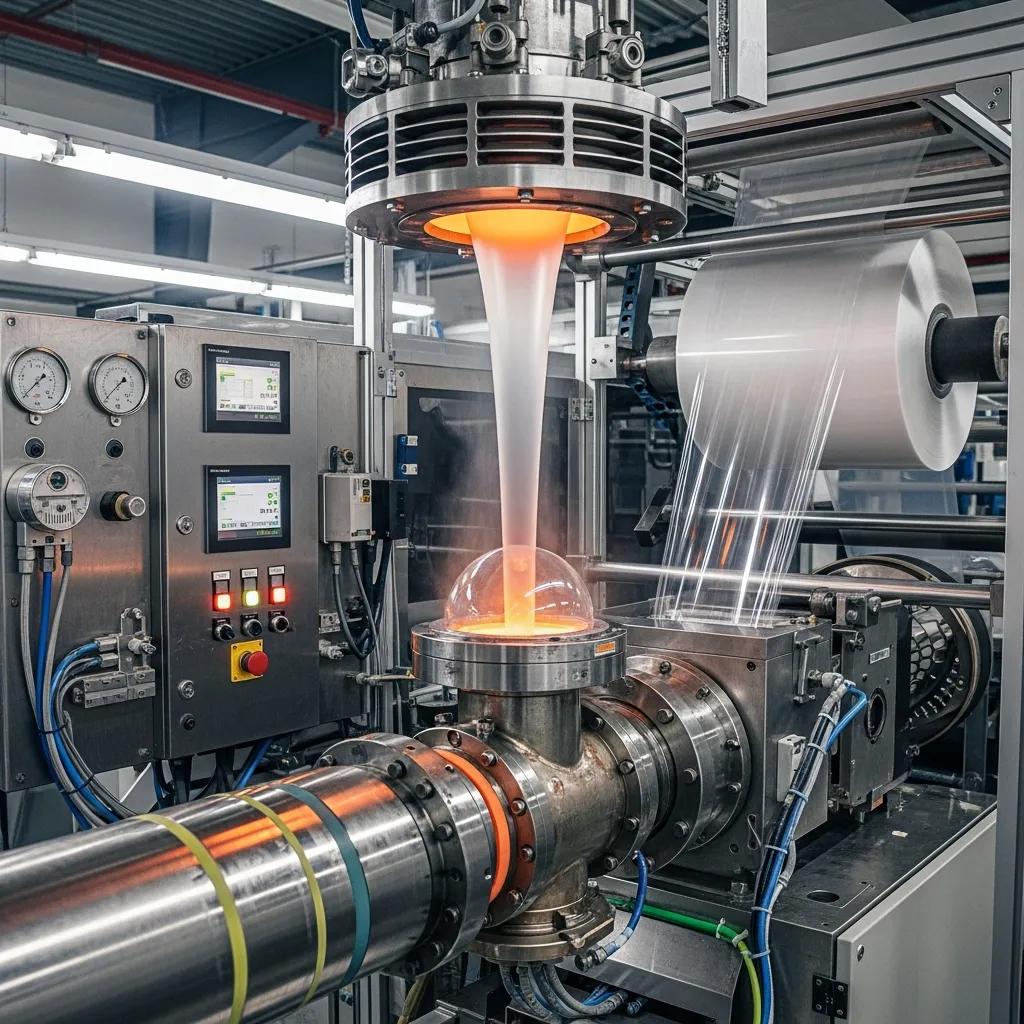

Blown film extrusion is the process of melting plastic resin and forming a tubular film by inflating a molten tube through a die and cooling it with an air ring; this method delivers uniform film thickness, superior tensile properties, and cost-effective multilayer constructions. The mechanism—extruder screw feeding, die head shaping, and a cooling ring controlling solidification—directly affects film clarity, strength, and gauge control, which in turn influence final bag performance and print quality. Multilayer co-extrusion enables combining functional layers such as a barrier or tie layer with structural and printable skins to meet specific product requirements, improving puncture resistance and sealing consistency. The table below compares monolayer versus multilayer extruder configurations to guide equipment choices for different product goals.

| Extruder Configuration | Film Width / Thickness | Production Speed | Material Compatibility |

|---|---|---|---|

| Monolayer extruder | Up to 1200 mm / 10–80 µm | Moderate | HDPE, LDPE, LLDPE |

| 3-layer co-extruder | Up to 1500 mm / 20–200 µm | Higher | Multilayer blends, barrier films |

| 5-layer co-extruder | Up to 2000 mm / 20–300 µm | High | Complex barrier + strength combinations |

This comparison shows that multilayer extruders increase flexibility for high-performance bags while enabling more reliable printing surfaces and barrier functions. Understanding these differences clarifies why producers aiming for branded, heavy-duty, or food-contact bags often prefer co-extrusion lines.

Critical blown film extrusion specs include screw diameter and L/D ratio, the design of the die head and air ring cooling system, and the control system for precise die gap and haul-off speed. A higher L/D ratio improves melt homogeneity, while an engineered cooling ring ensures consistent gauge and fewer defects like gels or thickness variation. Winding and layflat control directly impact downstream bag making by reducing web tension issues and improving registration for printing. Additional features such as pelletizers, melt filtration, and real-time thickness monitoring increase uptime and reduce scrap; these options are particularly valuable when integrating extrusion with high-speed bag making and flexo printing lines in Gauteng production facilities.

Multilayer film production combines functional layers into a single film structure so each layer performs a targeted role—outer print layer for aesthetics, middle structural layer for tensile strength and puncture resistance, and an inner tie or barrier layer for moisture or odor control. This architecture boosts overall mechanical properties without dramatically increasing material cost, delivering bags that resist punctures, retain prints better, and offer consistent sealing. For food-contact or heavy-duty applications, multilayer films allow fine-tuning of oxygen and moisture barriers while keeping the outer surface printable for high-quality flexographic graphics. Choosing multilayer over monolayer depends on a cost-benefit analysis tied to product needs; producers should weigh added equipment complexity and material sourcing against improved product performance and higher selling prices.

Sourcing a flexo printing supplier for film and bags in Johannesburg requires evaluating technical capability, spare-parts supply, and local service infrastructure. Flexo systems for film vary from in-line compact modules integrated with bag makers to full off-line presses for high-quality multi-color work; buyers should prioritize suppliers that provide plate-making services, ink compatibility guidance, and robust drying systems for faster line speeds. Local service is critical: access to replacement anilox rolls, plates, and knowledgeable field engineers minimizes downtime and protects print registration. Below is a checklist to evaluate suppliers and models, helping buyers shortlist vendors that match print quality, color capacity and service expectations.

Supplier checklist for flexo printing selection:

This checklist helps convert technical requirements into procurement questions that reduce risk and ensure predictable print quality and uptime.

Flexographic solutions range from basic 1–2 color in-line units for simple logo printing to multi-color in-line or off-line presses capable of full-color branding and continuous varnishing. In-line flexo integrated with a bag making machine reduces handling and preserves registration, while off-line presses offer greater flexibility for long-run, high-resolution work. Important considerations include plate technology, anilox cell volume for ink laydown, and solvent versus water-based ink systems that affect drying and environmental compliance. Choosing the correct configuration depends on run length, color complexity and whether print-on-demand or high-volume batch work is the primary business model.

Flexo printing transforms plain film into branded packaging that communicates product information, compliance labels, and marketing messages, thereby increasing perceived value and enabling premium pricing. High-quality printing enhances shelf presence and supports traceability through barcodes and regulatory marks, while functional inks (e.g., UV-resistant or scratch-resistant coatings) protect graphics under heavy use. For many retailers, printed bags serve as a mobile advertisement; for industrial users, print can include handling instructions and safety warnings that reduce misuse. Effective flexo printing therefore contributes directly to revenue-per-bag and can be a decisive factor when contracting packaging suppliers.

Machine pricing varies widely depending on automation level, print capability, multilayer extrusion integration, and whether recycling or pelletizing is included in the line. Entry-level single-head bag makers cost significantly less than high-speed multi-station lines that include in-line flexo printing and co-extrusion extruders. Other cost drivers include electrical control sophistication, servo drives, and the inclusion of quality-control sensors and automated winding systems. Below is a practical EAV-style table that outlines sample cost ranges and the main factors that influence those ranges, helping buyers set realistic budgets and evaluate ROI scenarios before requesting tailored quotes.

| Equipment Class | Typical Price Range (Indicative) | Primary Price Drivers |

|---|---|---|

| Entry-level single-head bag maker | Moderate | Basic automation, no printing |

| Mid-range shopping bag line with in-line flexo | Higher | Printing stations, servo controls |

| High-speed industrial garbage bag line with extruder | Highest | Multilayer extruder, high-speed winding |

Understanding these categories helps buyers decide which features are essential and where spending yields the best operational return.

Feature upgrades that markedly increase price include adding flexo printing stations, upgrading to multilayer co-extrusion, higher-speed specifications, and advanced automation such as servo-driven film handling and automatic roll changeovers. Printing and multilayer capability add both equipment cost and complexity for maintenance, but they often enable higher margins through premium branding and improved bag performance. When evaluating cost versus benefit, calculate expected production throughput, scrap reduction and potential selling price premium to determine the payback period for higher-spec machines. Vendors and suppliers typically provide financing or tailored quotes once specifications are finalized to reflect these trade-offs accurately.

Buyers in South Africa commonly use vendor finance, bank asset finance, leasing or structured installment plans to acquire manufacturing equipment while preserving working capital. Financing considerations include deposit requirements, loan term and local currency exposure; longer-term asset finance often aligns payments with expected revenue from the equipment. Speak with equipment suppliers to obtain indicative financing options and to receive a customized proposal that reflects the machine configuration, delivery timeline and expected commissioning support. For many purchasers, a staged investment—starting with an extruder and basic bag maker, then adding printing or recycling modules—spreads capital expenditure while scaling capacity.

Routine maintenance prevents downtime and preserves bag quality by keeping key meronyms—heating elements, timer switches, belts, sealing jaws and winders—in good condition. A structured maintenance cadence covering daily operator checks, weekly preventative tasks and monthly or quarterly inspections of critical components reduces unexpected stoppages. Prioritizing on-site spare parts inventory for items that frequently fail—such as timer switches, heating elements and belts—shortens repair times. The table below lists recommended spare parts and maintenance intervals to help managers plan inventory and service contracts.

| Component | Suggested Spare | Recommended Check Interval |

|---|---|---|

| Timer switches | 2 spares | Monthly functionality check |

| Sealing jaws | 1 spare set | Weekly alignment and wear check |

| Belts and drives | 2 spares | Weekly tension and wear check |

| Heating elements | 2 spares | Monthly temperature profile check |

A planned spare parts strategy combined with routine checks helps minimize production losses and maintains consistent bag quality, which leads naturally to defining where local service support should come from.

Daily operator checks should include verifying sealing temperature profiles, film tension, and visual inspection for contamination or wear; these short checks prevent small issues from escalating. Weekly maintenance should include lubricant application to bearings, belt tension adjustments and inspection of electrical connectors and heating elements. Maintain a prioritized spare-parts list—timer switches, belts, sealing jaws and heating cartridges—and keep critical items locally stocked to reduce lead times. Training operators in first-level troubleshooting and basic preventive maintenance increases mean time between failures and reduces reliance on external technicians for routine tasks.

When evaluating service partners in Gauteng and Randburg, prioritize response time, parts inventory and presence of field engineers who can perform on-site repairs and commissioning. Reliable suppliers advertise timely after-sales service, documented inspection regimes, and warranties on key components; some suppliers specifically offer two-year warranties on timer switches and a 100 percent final inspection before dispatch. Escalation procedures and agreed SLAs—such as guaranteed response windows for field engineers—are essential to minimize downtime and should be confirmed before purchase. Establish clear communication channels and maintain documentation of service visits to support continuous improvement of uptime and production stability.

Plastic Bag Machine South Africa serves as a local presence that offers one-stop solutions and ties several production capabilities—bag making machines, blown film extruders, flexo printing and recycling options—into coherent production lines for South African buyers. The company’s value propositions emphasize simple operation, dependable performance, easy maintenance, and timely after-sales service to reduce downtime and simplify training. Additional assurances include a 100 percent final inspection before shipment, two-year warranty coverage on timer switches and options for customization to meet specific production requirements. This combination of operational focus and practical guarantees helps manufacturers in Randburg and Gauteng get lines commissioned faster and run more reliably.

Plastic Bag Machine South Africa positions its offering around several buyer-centric advantages that address common manufacturing pain points. Simple operation reduces training time and staffing complexity by prioritizing intuitive controls and straightforward maintenance access. Perfect performance and easy maintenance are enforced through factory inspection protocols and a parts strategy that limits routine downtime. Timely after-sales service and warranty terms, including two-year warranty coverage on timer switches, provide tangible risk reduction for buyers; customization and a one-stop service approach let manufacturers commission lines built to specification rather than assemble disparate components.

South African converters and manufacturers benefit from faster commissioning, lower operating downtime and simplified after-sales coordination when choosing an integrated supplier model. Practical outcomes include more predictable production schedules and reduced staffing overhead because machines designed for simple operation require less specialized maintenance training. The company’s emphasis on customization and robust R&D support helps align equipment with local material availability—such as specific LDPE/LLDPE blends or biodegradable resins—so buyers can achieve targeted product specifications with minimal rework. For buyers planning a new line, requesting a tailored quote and discussing modular financing options is the next practical step to quantify expected ROI and delivery timelines.

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:008613088651008.

At Kingdom Machinery Co., Ltd., we pride ourselves on being a leading manufacturer of plastic bag making machines. Our commitment to quality and innovation ensures that our customers receive the best machinery tailored to their specific production needs. By choosing us, you are partnering with a company that has established itself as a trusted name in the industry.

Our extensive range of plastic bag machinery includes options for various applications, from shopping bags to biodegradable solutions. We understand the importance of efficiency and reliability in production, which is why our machines are designed for optimal performance, ensuring your business can meet market demands effectively.

Our plastic bag machines are engineered to provide numerous advantages, including ease of operation, low maintenance costs, and high productivity rates. These features make them ideal for businesses looking to enhance their manufacturing processes while keeping operational costs low.

Additionally, our machines are equipped with advanced technology that ensures consistent quality in production. With energy-efficient designs and robust construction, our equipment not only meets but exceeds industry standards, providing you with a competitive edge in the market.

We have had the pleasure of serving over 1000 satisfied customers across various regions, each with unique needs and challenges. Our commitment to customer satisfaction is reflected in the positive feedback we receive, showcasing the effectiveness of our machines in real-world applications.

From small start-ups to large manufacturing plants, our clients have successfully integrated our machinery into their operations, leading to increased productivity and profitability. These success stories underscore our dedication to providing tailored solutions that foster growth and innovation.

As a forward-thinking manufacturer, we continuously invest in research and development to bring the latest innovations to our plastic bag machines. This commitment allows us to offer cutting-edge technology that enhances production efficiency and reduces waste.

Our innovations include features such as automated controls, real-time monitoring systems, and environmentally friendly production processes. By adopting these advancements, our clients can not only improve their operational efficiency but also align with global sustainability goals.